Chapter 15

ROOFING

Introduction

Terminology

Standards

Roof Construction

Roof Coverings

Fire Protection

Underlays

Thermal Insulation

Shading

Roofing Accessories

Flashings

Waterproofing

Introduction

Roofing plays a very important part of a building, not only aesthetically but structurally. It is important that a roof, whether flat or pitched, is designed and installed correctly. Rain and wind can play havoc with a roof that has been installed badly or to the incorrect manufacturers’ specification; for example, the incorrect pitch, the incorrect application, or poor workmanship.

With an age of diversity in the building Industry and the abundant choice of design and materials, one tendency has become very clear; the increasing complexity of the geometry of buildings, and more especially of roofs. It is therefore simple to deduce that defects increase in direct proportion to this increase in complexity of geometry of the surfaces of buildings; i.e. at the intersections of different planes and materials. Notwithstanding certain roofs suit only certain designs.

Added to this is the increasing lack of properly skilled artisans in erecting roof structures and the fitment of the desired roof coverings, associated fittings and accessories; highlighting the need for taking extra care in both design and construction, when it comes to roofing.

It is also an element which requires the supervision of an engineer. Local authorities will not issue occupancy certificate to a building without an Engineer’s certificate that the roof complies with the standards as laid out in the National Building Regulations.

One must consider that a roof has numerous functions other than aesthetics that need to be taken into account in the design and erection process:

- Protection from sun, wind and rain.

- Strength and stability

- Durability

- Control of heat gain and loss – insulation

- Prevention of condensation

- Fire protection and prevention

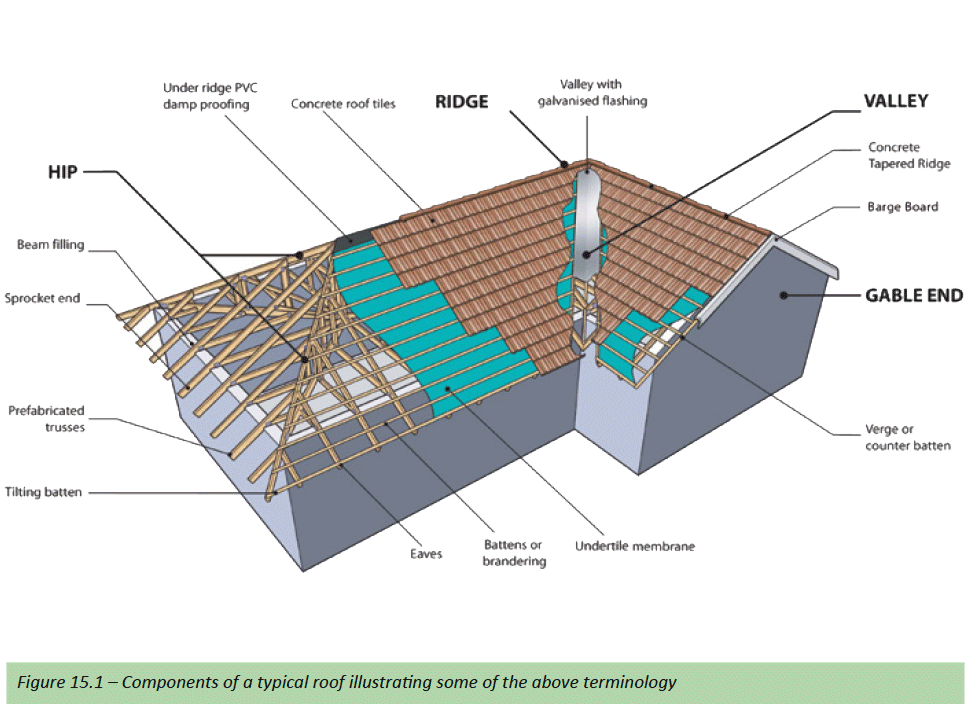

Terminology

Apex

The top of a truss (roof) where the two chords (rafters) meet.

Barge board

A barge board is a sloping roof trim fixed in lengths along the edge of a gable to cover the exposed timbers or as some describe as an ornamental board along the gable end of a roof.

Batten

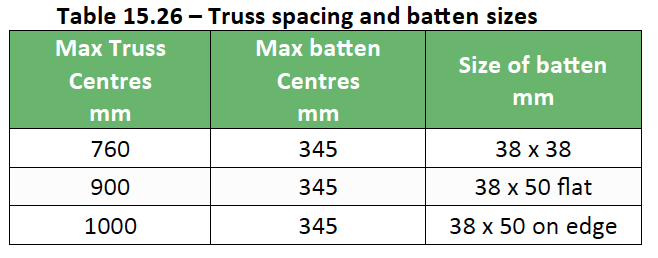

Pieces of timber usually SA pine 38mm x 38mm or 38mm x 50mm laid and nailed across the top chords of the truss at 90° at a spacing to suit the roof covering but less than 540mm onto which the roof covering is fixed or hooked and typically used in roof slate or tile applications (see brandering).

Beam filling

See Superstructure

Bottom chord

The part of the truss that forms the bottom edge that joins the two heel joints and supports the ceiling – also called the tie-beam.

Bracing

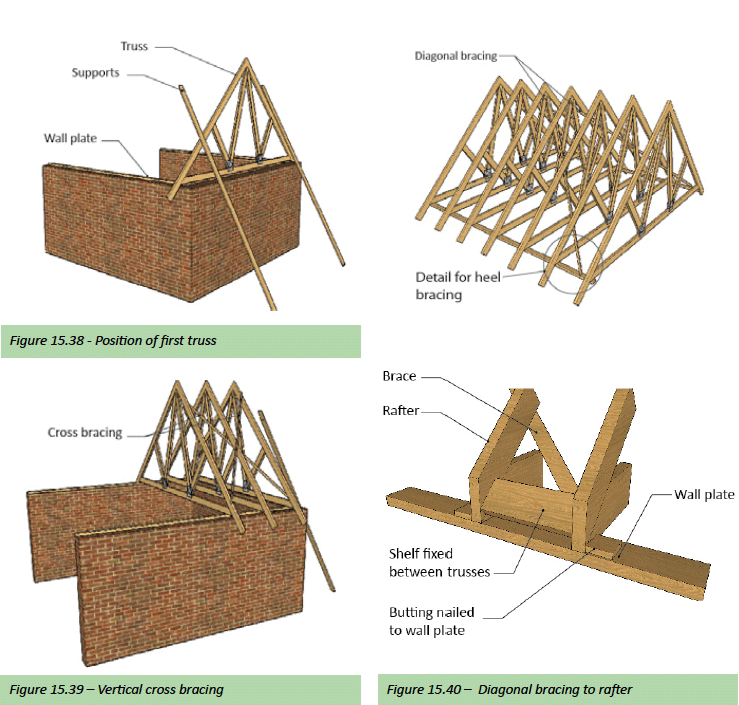

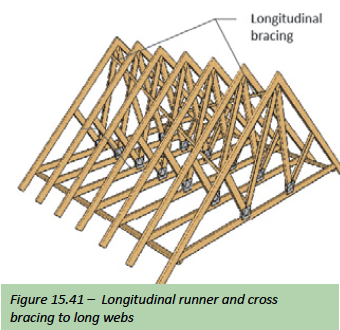

The members fixed to several adjacent trusses usually at a 45° angle to make the roof stable and to prevent buckling of compression members.

Brandering

Same as battens but fixed to the bottom chord to support the celling (see batten).

Double Pitch

Trusses where the top chords (rafters) slope up to the apex at the same angles (pitches) from both ends of the truss.

Dual Pitch

Trusses where the top chords slope up to the apex at two different angles (pitch) from each end of the truss.

Dutch hip

A hip end where the end slope does not reach the apex but the top part of the hip forms a small gable; also called a louver hip.

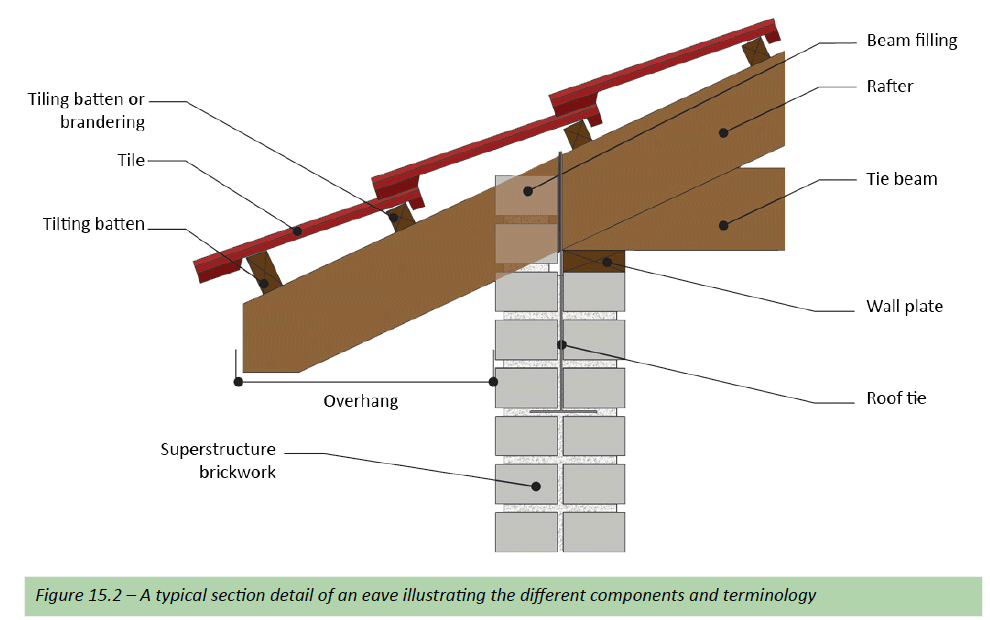

Eave

The under part of a sloping roof that overhangs a wall or a vertical surface (see overhang).

Fascia

A board or similar trim set on edge along the eaves to cover the rafter ends (sprocket ends) and can also carry a gutter, or a simple horizontal band that projects slightly from the wall surface below the edge of the roof.

Gable

A gable is the triangular upper part of a wall at the end of a pitched roof. There are different types of gable ends, and these relate to different architectural styles for example, Cape Dutch.

Gablet

Small gable on the roof slope, usually formed by a valley set.

Girder truss

A truss (single or multiple ply) used to support other trusses.

Hanger

A U shaped bracket made of light gauge galvanised mild steel used to support trusses on a girder or beam.

Heel

The truss end joint where the top and bottom chords connect, or where the end web joins the bottom chord in stub and mono-pitch trusses.

Hip

A hip is an outer intersection between two sloping surfaces of a pitched roof – water flows away from a hip.

Hurricane clip

A light gauge galvanised mild steel angle bracket used to fix two timber members at 90° to each other.

Insulation

Insulation in roofing is a material used to prevent heat loss and/or heat gain through a roof. The insulation membrane can also provide fire protection as well as a control against condensation (if correctly installed) in sheeted roof applications.

Jack rafter

The smallest end part of a hip corner construction using only single pieces of timber (loose rafter).

Jack Truss

The mono pitch trusses of the hip which are supported at the high end by the hip girders.

Mono Pitch

A truss where there is only one rafter slope.

Nib

Extensions of the bottom chord past the truss end, usually to support the truss in brickwork or on a truss hanger.

Overhang

The part of the truss top chord that extends past the truss heel. Measured horizontally from the truss heel, but from the outside wall face of the building.

Pitch

The angle of a roof as measured off a horizontal plane.

Plumb Cut

Top chord (rafter) overhangs are usually cut off vertical, to allow the fixing of fascia boards and/or a gutter at the roof truss ends (sprocket ends).

Polynesian

Trusses with a pitch change in each top chord from a lower pitch to steeper pitch going from heel to apex.

Portal frame

A frame of two columns with one horizontal roof beam between them, or two sloping rafters that join in the middle.

Purlin

These are pieces of timber usually SA pine 76mm x 50mm laid and nailed at 90° across the trusses or beams onto which the roof covering is fixed and typically used in sheeted roof applications.

Rafter

A sloping roof beam, usually from eave to ridge. The term rafter is also applied to all types of trussed rafter, the sloping beam of a portal frame, and the principal rafter of a truss – also known as the top chord.

Roof and roofing

A roof can be defined as the upper structure for and covering of a building, and roofing as the materials which form that covering.

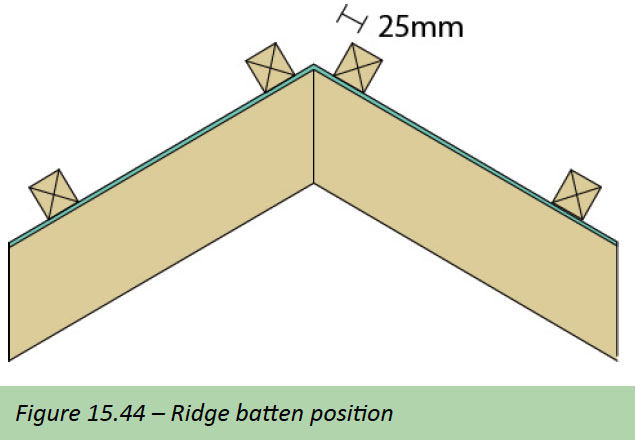

Ridge

The horizontal line on top of a pitched roof (the apex) usually covered, for example with ridge tiles.

Spacing

The distance between the centres of two of the same elements, i.e. trusses.

Span

The span is the distance between two supports (usually walls) onto which a truss or beam rest.

Stub end

Also called a stub heel; where the top and bottom chords are some distance apart and connected by the first truss web.

Tie beam

The bottom horizontal member of a roof truss equal in length to the span of the roof – also known as the bottom chord.

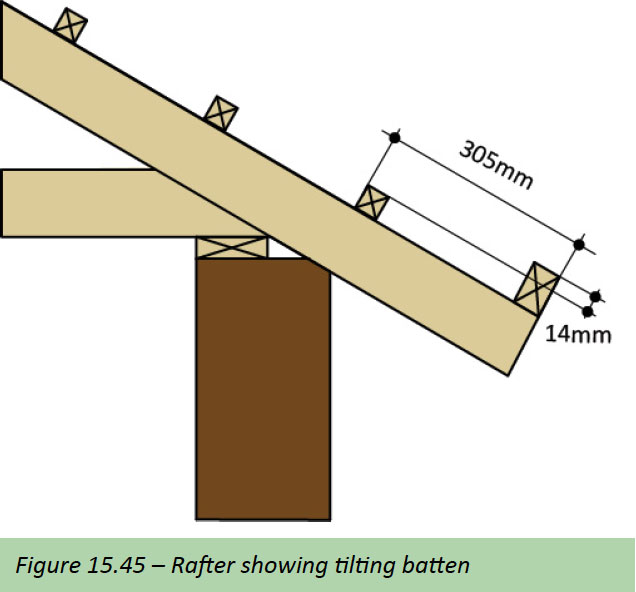

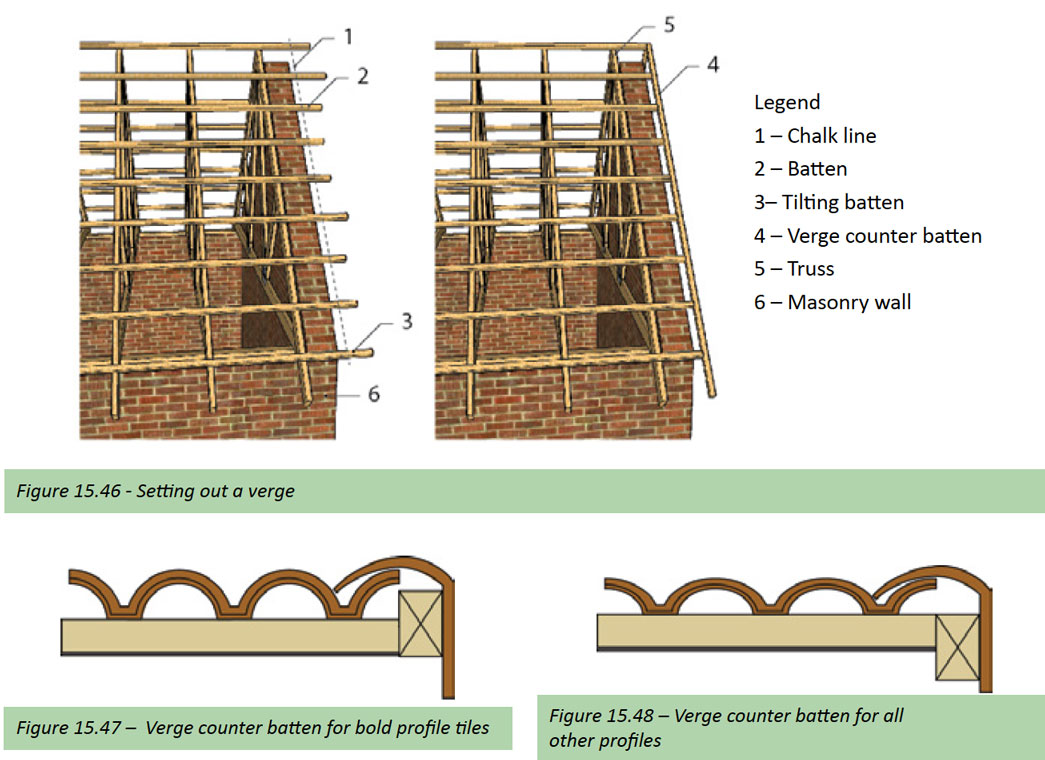

Tilting batten

Also known as a tilting fillet; the tilting batten is the last batten at the bottom edge of the rafter. It is larger than the battens and usually 76mm x 50mm and sometimes cut to triangular shape in cross-section. It lifts the end of the last tile or slate.

Top chord

Also called a rafter; the part of a truss, which forms the top edge usually at a slope and has the battens or purlins fixed to it to carry the roof covering.

Truss

A truss is a rigid structural framework of timbers or steel members bridging a space with each end of the truss resting on some form of support, usually walls. The trusses provide support for battens or purlins which in turn support the roof covering, e.g. roof tiles. Trusses are often prefabricated and brought to site, but can also be built on site.

Underlays

Underlays can be fitted under the tiles or roof covering to assist with waterproofing should the concrete tile or other roof covering fail; the underlay can also act as an insulating membrane or vapour barrier. An underlay in roof tile applications is also used to prevent dust from entering the ceiling/roof space.

Valley

A valley is an inner intersection between two sloping surfaces of a pitched roof – water flows towards a valley.

Vapour barrier

Impervious barrier that prevents the passage of water vapour through building components.

Verge

The sloping edge of a pitched roof above a gable. A verge can overhang or be flush with the wall.

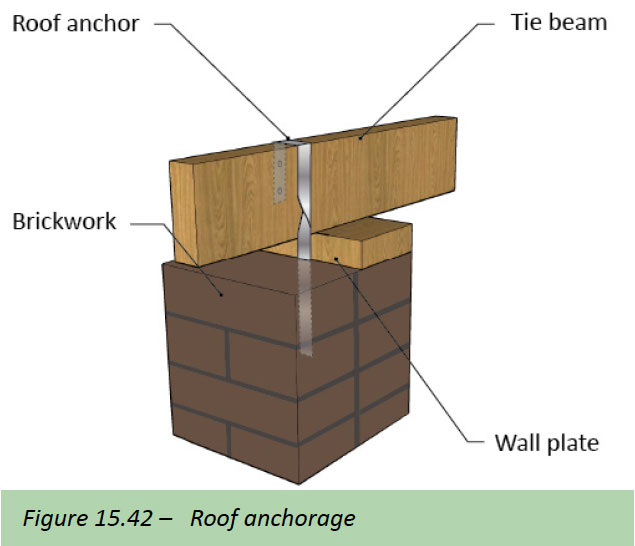

Wall plate

A piece of timber usually SA pine 76mm x 38mm placed flat on top of the supporting wall (completed brickwork) on the inside skin acting as a flexible and bearing surface for the trusses or beams to be placed and fixed and to spread the load.

Webs

The truss members that connect the top and bottom chords together.

Standards

SANS 10400 establishes general requirements for satisfying the National Building Regulations issued in terms of the National Building Regulations and Building Standards Act, 1977 (Act No. 103 of 1977), and some of these requirements that are deemed to satisfy the following parts of such Regulations of Part L: Roofs are highlighted below:

L1 General Requirement

The roof of any building shall be so constructed that it will:

- a) Resist any forces to which it is likely to be subjected

- b) Be durable and waterproof

- c) Not allow the accumulation of any rainwater upon it surface, and

- d) As part of a roof and ceiling assembly provide adequate height in any room immediately below such assembly.

LL3.3

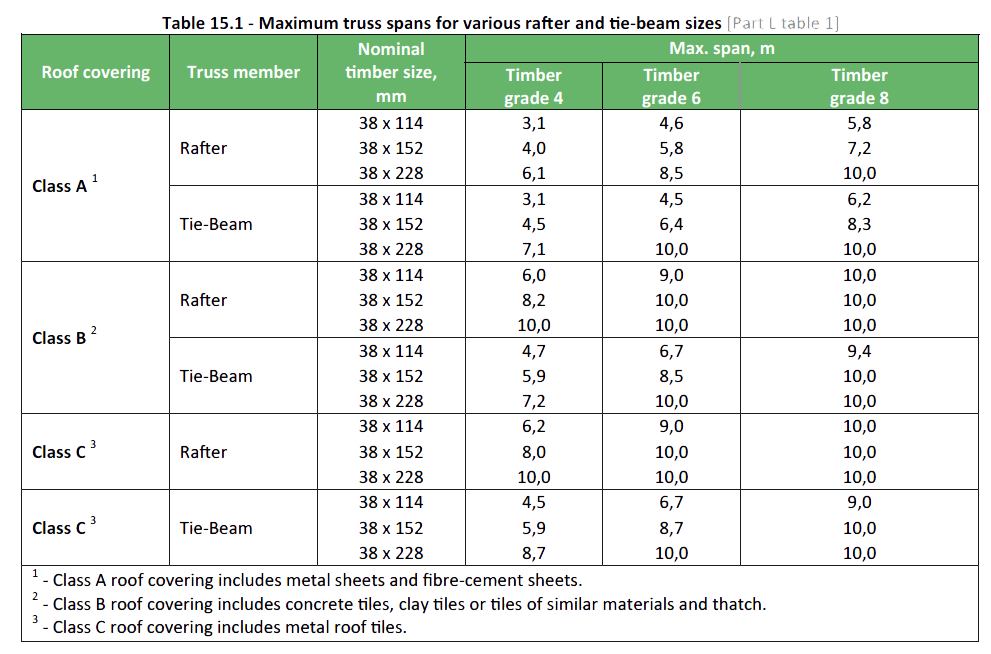

The requirements of subrules LL3.4 and LL3.5 shall apply only to single or double pitched Howe-type trusses, with a span of not more than 10 m, supported at heel joints only and having bays of equal lengths of not more than 1.5 m.

LL3.4

- (a) Where the roof covering is of the class given in column 1 of Table 11.1 the size of rafter (top chord), tie-beam (bottom chord) and the grade of timber to be used shall be selected from such table in such a way that the desired truss span does not exceed the relevant figure for maximum truss span given in column 4, 5 or 6, as the case may be.

- (b) All web members shall be not less than 38 mm x 114mm Grade 4 timber.

- (c) Where rafter and tie-beam sizes are to be determined from Table 15.1, the slope of the roof shall –

- (i) be not less than 15° nor more than 30° for Class A or Class C covering; and

- (ii) be not less than 17° nor more than 35° for Class B covering.

Commentary

Table 15.1 may seem confusing or even incorrect since the same nominal timber sizes appear to be capable of supporting either a Class A (light) or a Class B (heavy) roof covering and in the case of the heavier covering, greater truss spans are permitted. This apparent anomaly is negated when this table is read in conjunction with subrule LL3.6 (see below), as the centre-to-centre spacing of trusses supporting Class B roof covering is limited to a maximum of 760 mm compared with 1400 mm for Class A roof covering. The load per truss for a roof supporting a Class B covering is therefore less than that for a truss supporting a Class A covering.

It would appear from the table that in certain cases the use of a better grade timber is of no advantage as it does not lead to any increase in the maximum span that is permitted. The figures have been included in order to complete the table but the restriction on span is artificial in the sense that it is not directly related to the capability of the timber. The fact that no span of more than 10m has been included in the table serves only to draw attention to the fact than any roof supported on walls complying with the rules contained in Part K of SANS 10400 is restricted to a maximum span of 10m. It is also important to note that the values quoted in this table should only be used subject to the further limitations that –

- (a) the truss configuration is that of a Howe-type truss (see fig.15.4) and the maximum span is limited to 10 m;

- (b) the slope of the roof is –

- (i) more than 15° and less than 30° for Class A or Class C roof covering; or

- (ii) more than 17° and less than 35° for Class B covering.

LL3.6

The centre-to-centre spacing of trusses relevant to the roof covering to be applied shall not exceed:

| Class A | |

| Sheets, either metal or fibre cement | 1400mm |

| Class B | |

| Concrete tiles, clay tiles or tiles of similar material | 760mm |

| Metal tiles | 1050mm |

Roof Construction

Outline

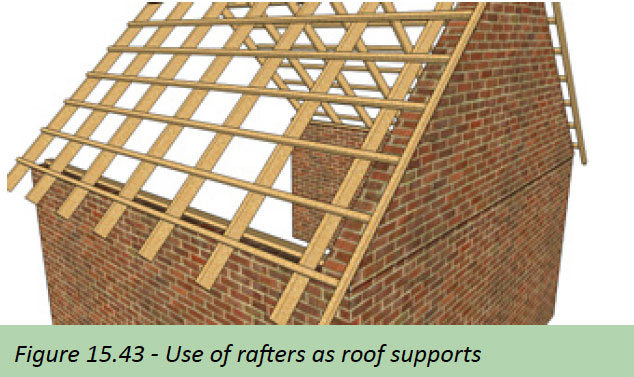

Roofs used in domestic and small commercial buildings are usually constructed by using timber roof trusses and/ or rafters and in certain applications timber poles. While in larger commercial and Industrial buildings, portal frames or girders using steel are more commonly used.

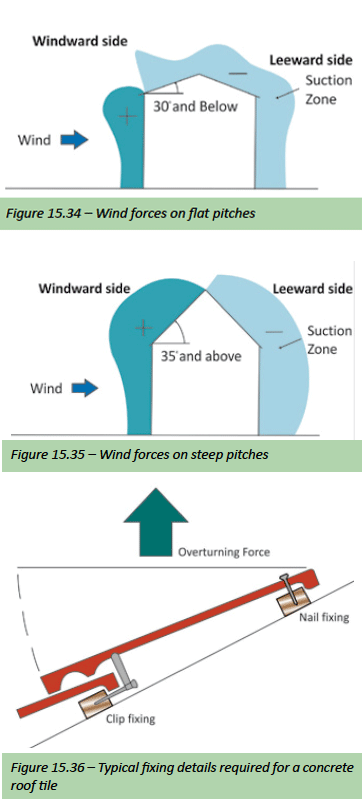

The need for taking care in the design, the construction and erection of roofs and fixing of the roof covering is essential to insure water penetration into the interior of the building is avoided. There is an absolute requirement in roof construction to prevent water reaching the interior of a building and where two kinds of rainfall intensity need to be considered:

- Rain falling vertically

- Rain driven by wind

Both categories contribute to the total quantities of rainwater needing disposal, but the second category particularly affects the weather tightness of lapped roofing, such as tiles and slates, and even the direction and extent of lap of larger sheets; with many manufacturers recommending the use of underlays, fixing of tiles etc. in these applications.

One must remember that rain falling while the wind is blowing affects pitched roofs more than flat (and walls even more so), it is therefore important to consider ones geographical location, associated weather patterns and not only your desired roofing requirements when deciding on an appropriate roofing design. Roofs can be flat or pitched and are made up of a variation of elements, types and shapes.

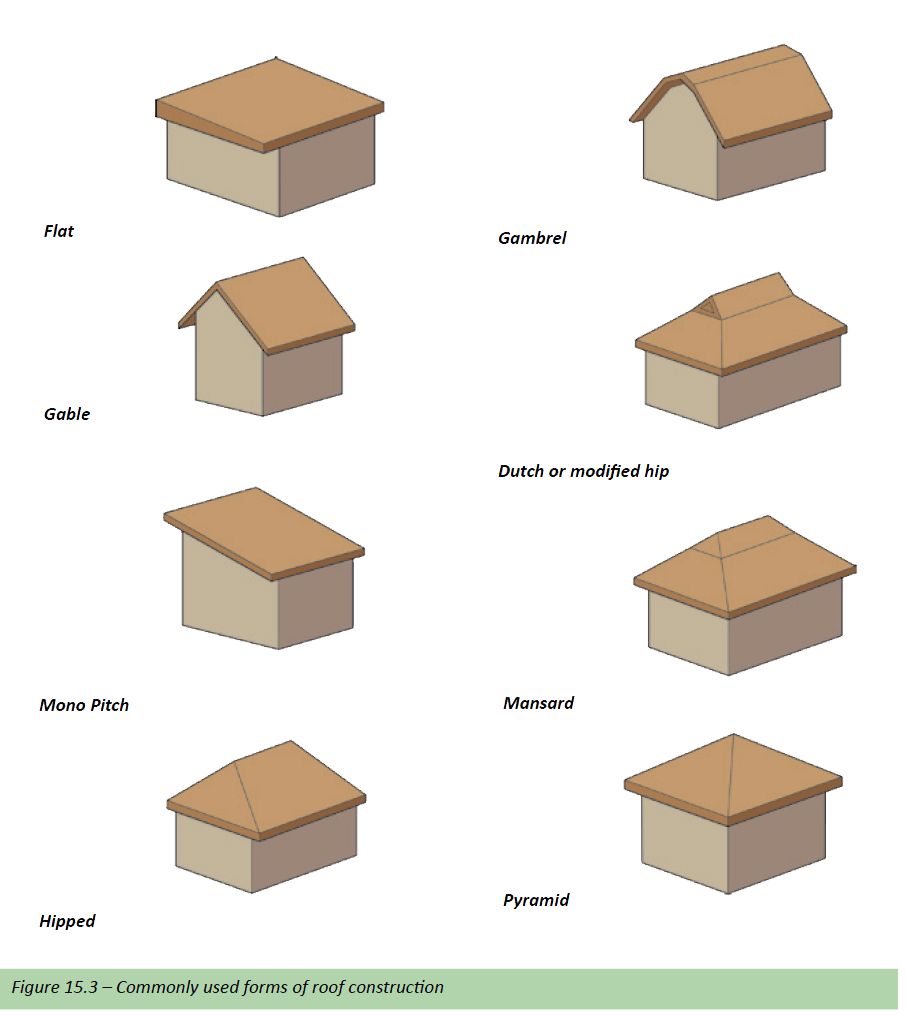

Roof Forms

The most commonly found forms of roof construction include the following:

Roof trusses

A roof truss is a coplanar (forces lying in the same plane) assembly of structural members made from timber or steel joined at their ends. The diagonals form triangles, producing a rigid framework. Triangulation is the fundamental concept behind the design of a roof truss; a triangle is the only multisided geometric figure that is rigid and will not move or rotate provided a structural member doesn’t bend or a connection (join) fail.

Roof trusses act like beams and support a roof and all imposed loads. A roof truss consists of top and bottom chords and a system of webs. The slope of the top chord (the pitch) can vary as required to suit the roof form, design and roof covering.

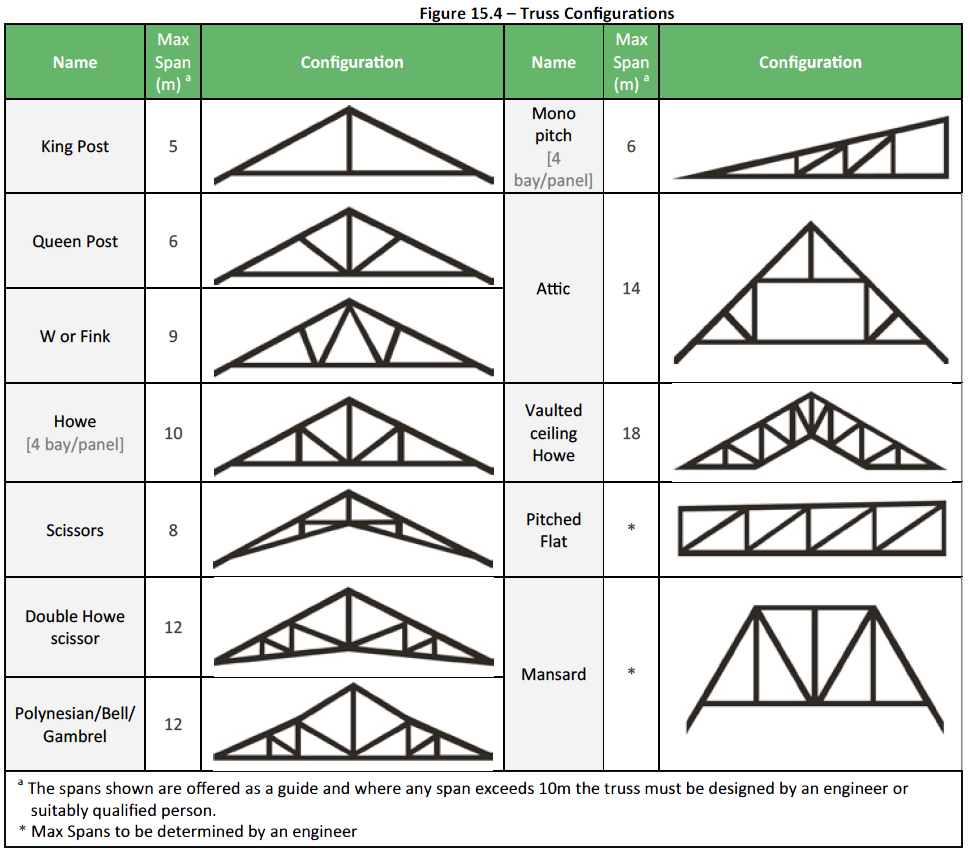

Truss Configurations

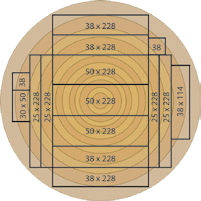

Some of the more commonly used truss configurations are illustrated in figure 15.4 below.

Timber Trusses

Timber trusses are widely used in the construction of roofs and for all types of buildings. They can be easily erected on site, are relatively easy to handle and can span the width of most buildings without interior load-bearing walls being required.

Site made trusses

Roof trusses manufactured on site must comply with the minimum “deemed to satisfy” requirements for nailed and bolted trusses of SANS 10400 or be designed by a professional engineer or other competent person.

Some local authorities will require an engineer’s certificate for the roof truss construction before issuing an occupancy certificate and similarly some financial institutions won’t make final payment without an engineer certifying the roof construction.

The requirements of the National Building Regulations are that the truss, single or double pitch, shall be a ‘Howe’ type truss (see figure 15.4) with a span not exceeding 10m for double pitch trusses and 6m for single pitch trusses.

The trusses must be supported at heel joints only and have bays of equal lengths not greater than 1.5m.

Then depending on the class of roof covering, the size of the rafter (top chord), tie-beam (bottom chord) and the grade of timber to be used it must be selected from table 15.1 in such a way that the desired truss span does not exceed the relevant figure – see LL3.4 under standards above.

For more on timber grades and sizes see the next sub-section on materials.

The spacing of site made roof trusses must be in accordance with SANS 10400 Part L: Roofs – LL3.6 – as described under standards above.

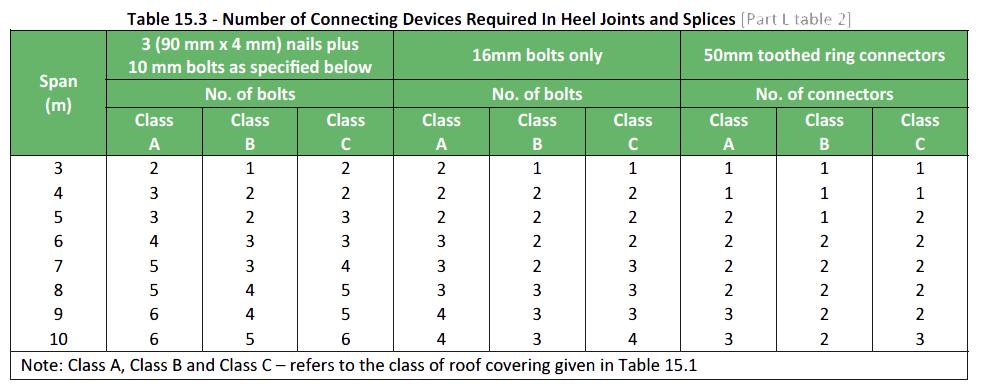

The number of connecting devices to be used at each intersection between two members at any heel joint or any splice in a site made truss shall be determined from table 15.3. In the case of any joint other than a heel joint or splice, one 10mm bolt plus four clinched 90 x 4mm nails shall be used.

To ensure a high standard of finish, it is essential that the roof structure is properly constructed. Poor workmanship and warped timber will reflect on the finished product and may result in deflection and distortion of the roof.

- Select a level surface to work on.

- Set out the first truss according to the span and pitch of the roof.

- Mark out the timber for the various members of the truss and cut accurately.

- Assemble the truss by nailing and bolting through the two thicknesses of timber and clinch the nails over on the reverse side – (see table 15.3).

- The bolts must have a washer on the nut end as the cup head pulls tight into the timber.

- The completed truss can now be used as a jig for the construction of the remaining trusses of the same size.

Prefabricated trusses

A network of prefabricated timber roof truss manufacturers can be found throughout South Africa. These fabricators operate under licence to suppliers of nail-plate connectors and use computer design programs devised by professional engineers. These fabricators are trained and equipped to offer advice and solutions for any shape of roof, any pitch or span for new structures, or to match existing roofs and since they are carefully engineered and factory built, prefabricated trusses have a consistent, reliable quality.

For the purposes of municipal approval (when required), design calculations can be issued, together with the appropriate roof layout, truss diagrams and any explanatory notes that may be needed.

When placing orders with a truss fabricator, or when a quotation is required, the fabricator must be provided with the following minimum information or given a detailed roof drawing covering the following:

- Overall span of roof

- Eaves overhang

- Pitch of roof

- Cantilever distance (if any)

- Roof covering

- Ceiling materials, plus any special loads

- Geyser position and capacity

- Other details which may affect the design e.g. solar panels

In most instances the truss fabricator would make a site inspection prior to manufacture of the trusses, to ensure dimensions and building work match that of the drawings originally provided.

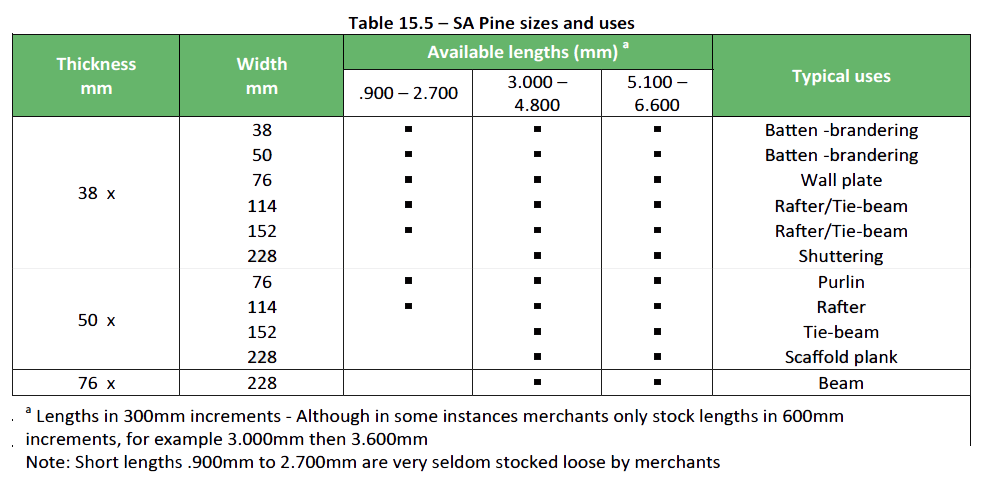

Materials

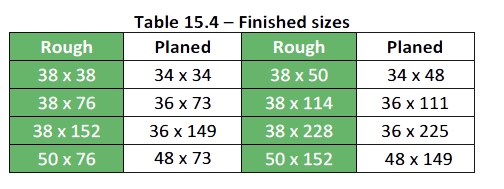

Structural timber suitable for all normal building work is covered by SANS 1783-2004, which defines visual stress grades and mechanical stress grades. The compulsory grading of timber prescribes that under grade structural sized timber is clearly marked with black crosses (known as black cross) on both ends to distinguish it from graded timber bearing the appropriate SANS mark for the various visual grades.

In order to obtain the permissible stresses, stress grades are adjusted by means of the appropriate modification factors which relate to the specific conditions of use. Structural timber can be used to its full safe load-bearing capacity, and hence more economically, in engineered structures if it is stress-graded. S5 is the most commonly used on site timber; and S7 or mechanically graded timber is used for engineered designed prefabricated trusses.

Finishes

Timber is available in three different types of finish, to suit specific applications;

- Rough Sawn or

- Sized or

- planed

Rough sawn timber (RGH)

Timber sold as rough has no further planing done to it after milling; also known as fine sawn. Structural sizes 38×152,

38×228, 50×152, 50×228 and 76×228.

Sized timber

Structural sizes 38×38, 38×50, 38×76 and 38×114 are generally sold as “Sized”. These products have been planed slightly to a consistent size to allow accurate truss manufacture and exact framing of buildings. The afore mentioned sizes are generally planed to 36×36, 36×47, 36×73, 36×111.

Planed timber (PAR)

Is a smooth finish which suits certain applications e.g. exposed trusses requiring painting. Planed timber has to be ordered as the process involves rough or sized timber, placed in a planing machine which then planes each side of the timber. As planing reduces the size of timber a decrease in strength can be expected.

Generally, the SABS allow a +3 -2mm tolerance on the thickness of rough sawn, kiln dried SA Pine. The lengths could be up to 50mm longer than that stated. 0.900 to 2.700 metre lengths are referred to as short lengths and 3.000 to 6.600 metre lengths as long lengths; which are also priced differently to that of short lengths. Lengths longer than 6.600 metres are available as finger- jointed timber.

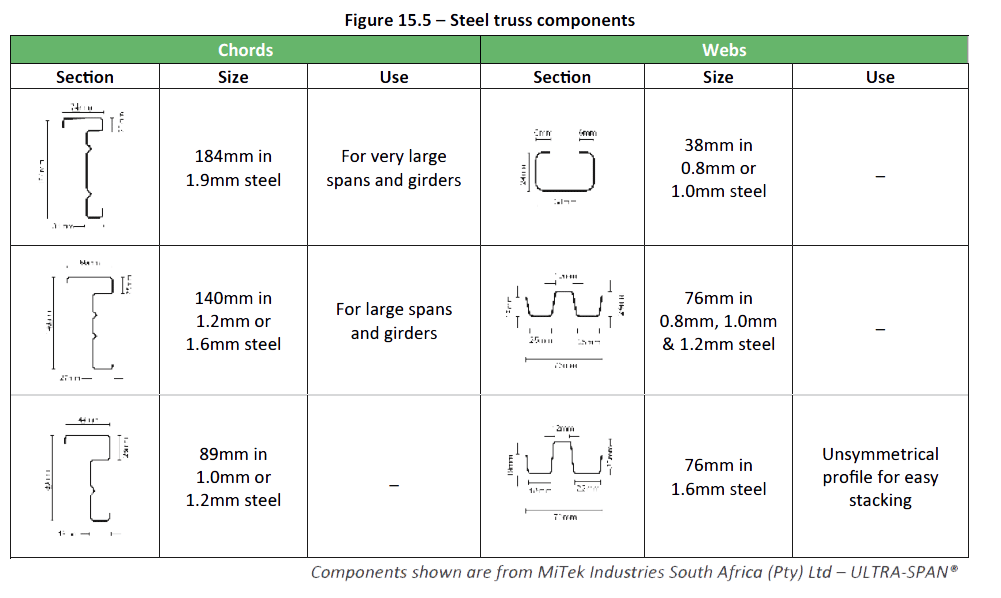

A number of steel truss systems are available for roof construction. Included are roof trusses, open-web joists and space frames. Open-web joists are a type of truss. They are light-weight structural members made from steel angles and bars. They, like other trusses, are end bearing and can span long distances in roof construction. Space frames are a three dimensional truss system. They provide a structural frame that spans in several directions and over large areas with a minimum number of vertical supports (columns). Steel trusses consist of top and bottom chords and a system of webs. Steel trusses are manufactured using galvanized mild steel and depending on the system and manufacturer.

the material sizes and thicknesses differ quite considerably. Steel trusses are designed and usually prefabricated although for low-cost housing or geographically remote projects steel trusses can be supplied in kit-form and assembled on site. The biggest advantage of using steel is that it is lightweight and compact which improves handling and erection on site and is economical to transport. Another is the span capability of steel where clear spans of up to 40metres are possible. Lastly steel is non-combustible and is more suitable for certain applications. Some examples of steel truss components showing sizes are illustrated below:

Rafters and Beams

The difference between a rafter and beam in roofing is a matter of description and use. A rafter is a sloping roof beam typically in timber, which is fitted from eave to ridge and used in place of roof trusses for aesthetic reasons by design or purpose. Whereas a beam can be described as a structural member that carries a load and can be in timber or steel. Rafters can also be described as girders, joists or bearers, the latter describing supports for a suspended floor. Beams can also be used to carry timber trusses or poles and are then built into the structure (walls) of the building and/or spanned between columns to support a roof. Materials used for rafters and beams Timber Laminated beams Laminated beams can be used for beams and rafters as their properties provide to carry greater loads and spans (up to 15 meters) than that of normal structural pine and are available in the following popular sizes – these sizes can vary slightly from manufacturer to manufacturer.

- Thickness: 35, 45, 70, 102, 140 mm

- Depth: 147, 231, 297, 330, 363. or up to 990 mm in 33 mm multiples

- Finish: PAR. or Fine Sawn

- Use: Internal & External Use. (Should be specified)

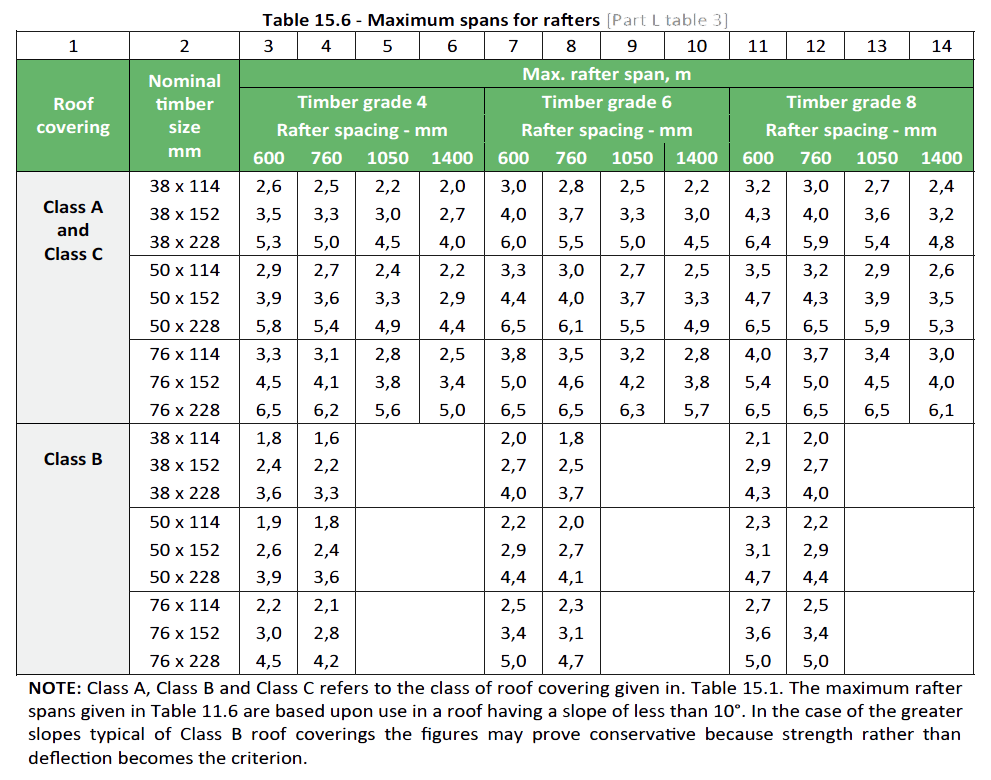

Rafters

Extract from SANS 10400 Part L: Roofs

Where rafter construction is used in place of roof trusses and the roof covering is of the class given in column 1 of Table 15.6 the size of rafter and grade of timber to be used shall be selected from such table in such a way that the rafter span does not exceed the relevant figure for maximum rafter span given in columns 3 to 14, as the case may be. Where rafter spacing differs from that in Table 15.6, intermediate values of maximum rafter span may be interpolated within the range of values given, for the relevant timber grade.

Steel

Steel is an alloy of carbon and iron, which is hard, tough, elastic, and capable of resisting various stresses and loads. Mild steel is the most popular steel used for general structural beams used in roofing. Steel sections come in a number of different shapes and sizes and the most popular sections used in roofing are the I-Beam; Channel; Angle Iron and T-Section. We have only highlighted these components very briefly in the section as timber is the more commonly used material used in residential and smaller type commercial buildings.

Note: For more on steel sections and sizes see Metalwork section.

Timber Poles

Commonly referred to as ‘Gum’ poles from the Eucalyptus (Gum) tree from which poles are cut. (Eucalyptus – Grandis/Saligna)

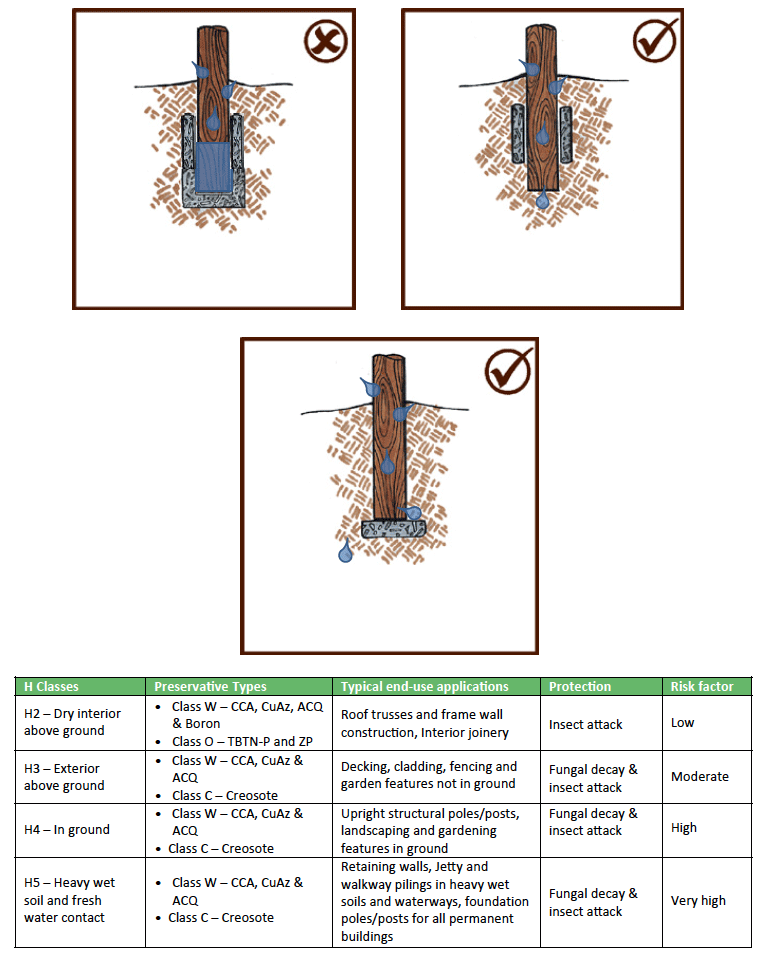

Round poles are typically used, for the timber frame construction of thatched roofed buildings. They are of course used for many other applications e.g. Props, fencing, bearers, pergolas etc. Timber poles and associated products are available untreated but are usually treated in one of the following:

- Creosote or

- CCA or

- TBTO (Tanalised) or

- Flambor (preservative and fire retardant (Boron based preservative)

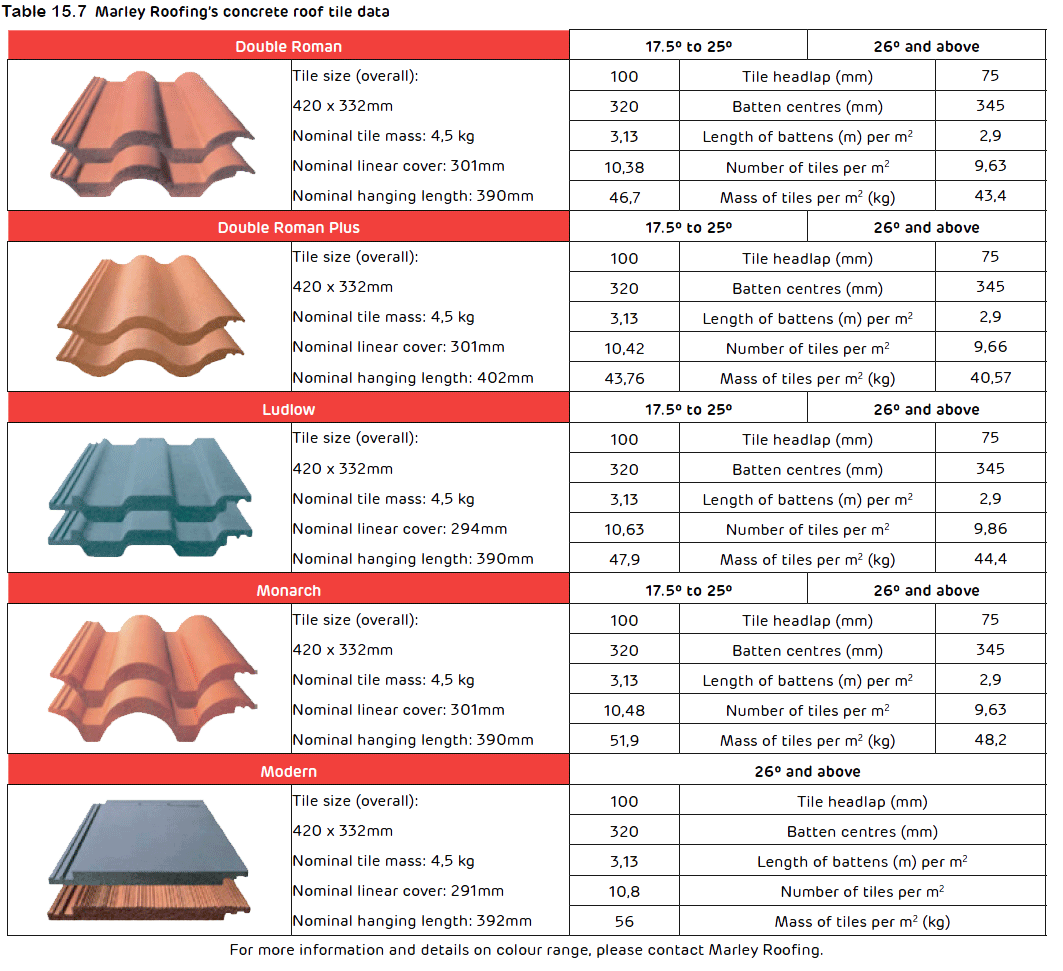

Benefits of Marley Roofing’s Concrete Roofing Solutions

- Longer lasting – Marley Roofing’s concrete roof tiles continue to strengthen over time and this is why concrete roofs that were constructed more than 40 years ago are still intact today.

- More variety – The raw materials and pigments used in the manufacture of roof tiles lend themselves to a number of distinctive tile designs to choose from

- Strength and durability – Moisture, which can undermine other building materials through rust or rot, has no weakening effect on Marley Roofing’s concrete roof tiles.

- Low maintenance – Marley Roofing’s concrete roof tiles are inert and compact, meaning that they won’t lose their key properties over time and therefore require less cleaning or repainting.

- Affordability – Double Roman “Plus” is a lightweight roof tile which does not compromise the properties or quality of the product, catering for the needs of the price-conscious customer.

- Eco-friendly – Marley Roofing’s roof tiles are recyclable and manufactured through environmentally-conscious processes to reduce the environmental impact through all stages of the roof tile’s lifetime.

- Energy Efficient – Superior thermal efficiency is obtained through insulated concrete.

Nail lengths for different tile profiles

- Monarch – 90mm

- Double Roman – 75mm

- Double Roman “Plus” – 75mm

- Ludlow – 63mm

- Homestead – 63mm

- Modern – 50mm

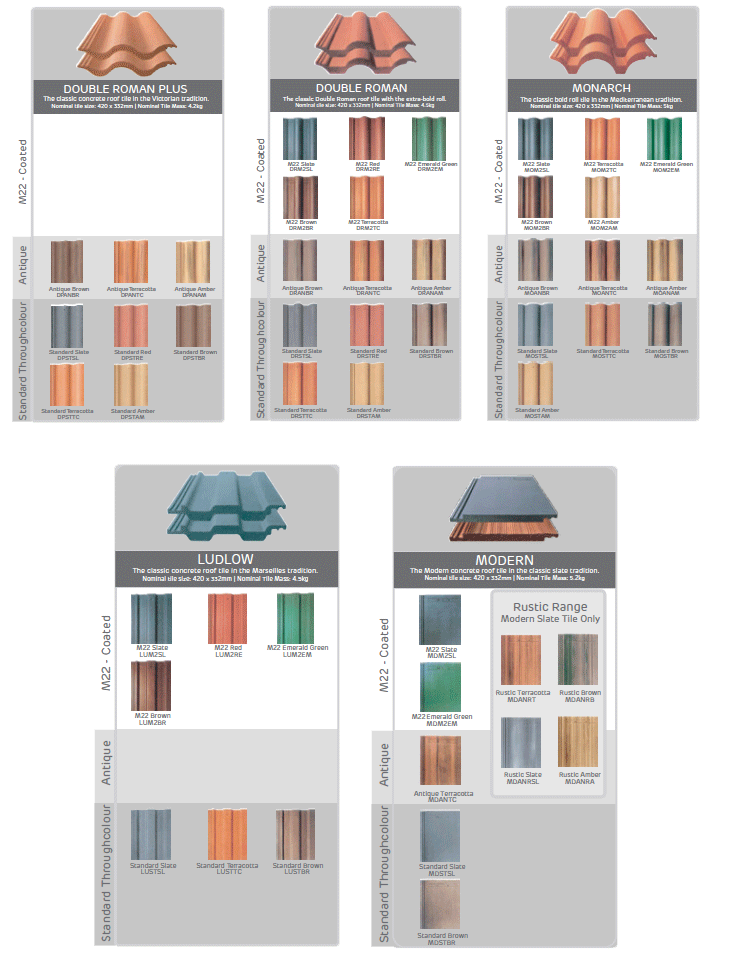

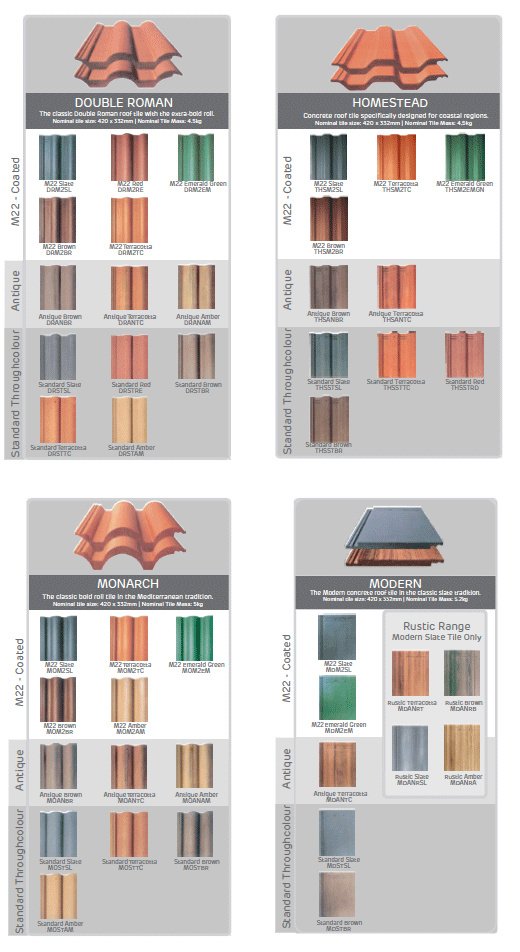

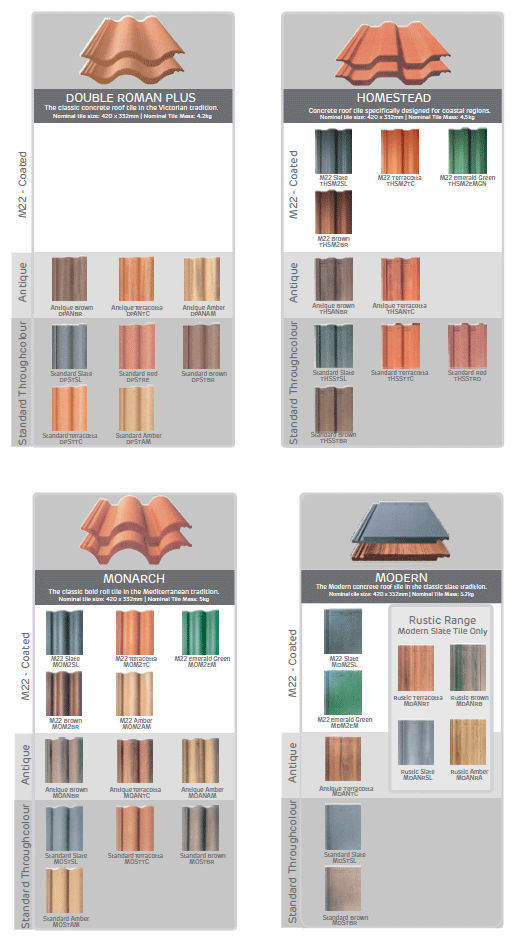

Inland Tile Range

KwaZulu Natal Tile Range

Western Cape Tile Range

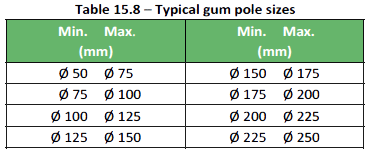

Round Poles are available in the following diameters from nominal Min. diameter to Max. diameter.

Available in lengths starting at 1.800m up to 7.800m – in 600mm increments. Longer lengths are available up to 13.000m

Slabbed and split poles

Saplings/Laths

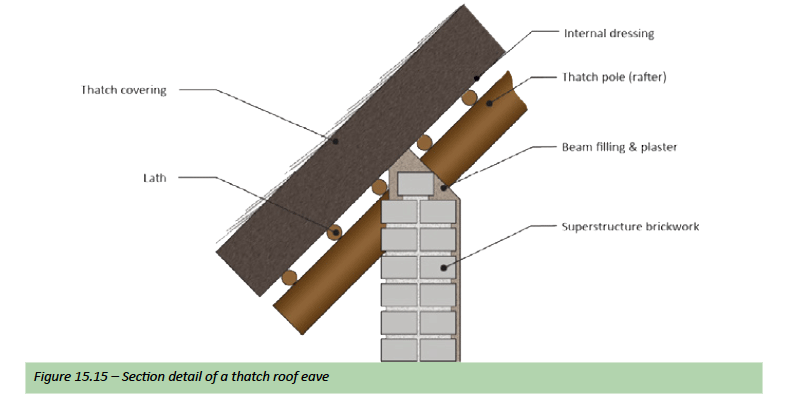

Laths or saplings serve the same purpose as battens and are used for tying/fixing thatch in thatch roof applications; also used for fencing and decorative applications. Available in diameters from 15mm up to 30mm; and in lengths from 1.800m up to 4.500m.

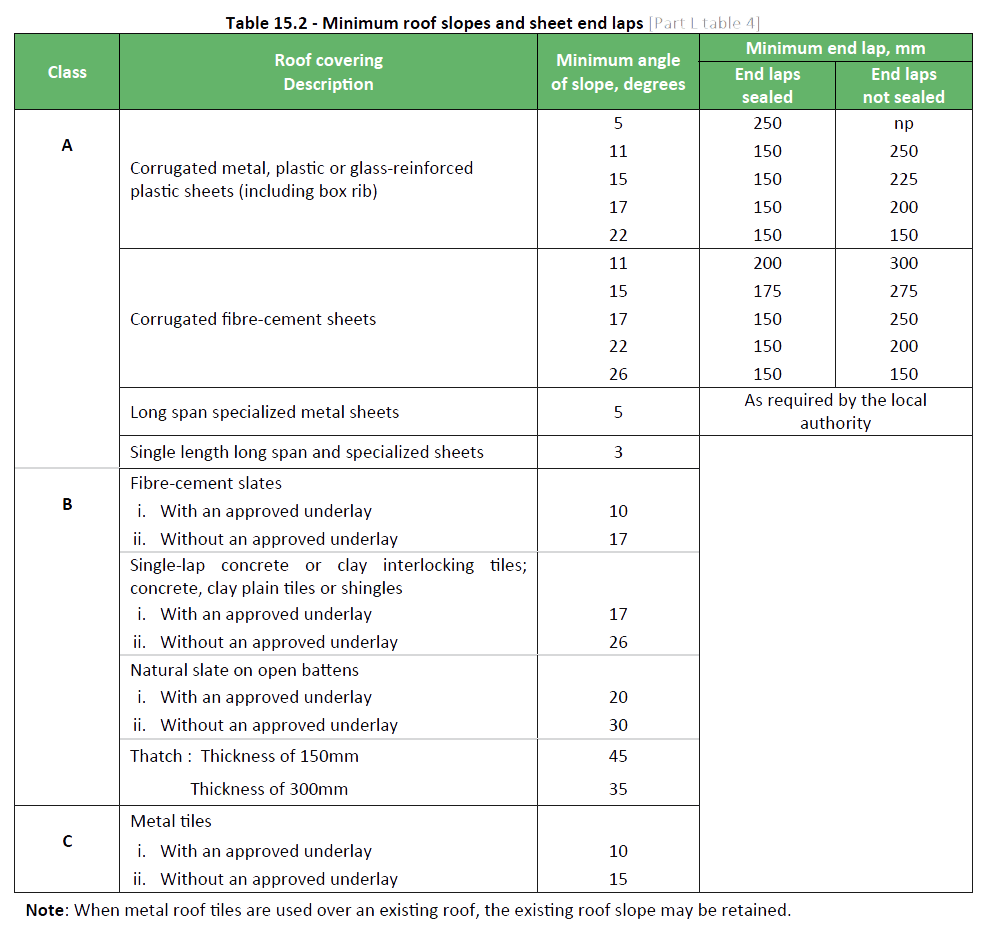

Roof Coverings

Outline

The following sub-sections discuss briefly the various types of roof coverings in common use; also showing the three different classifications of roof covering as described in table 15.1.

Roof Tiles

Concrete (Class B)

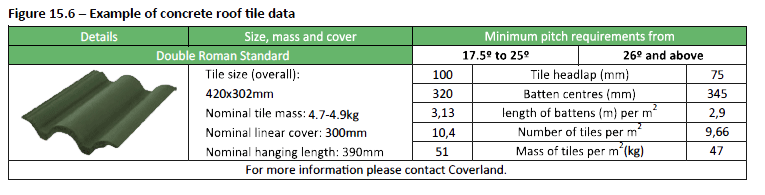

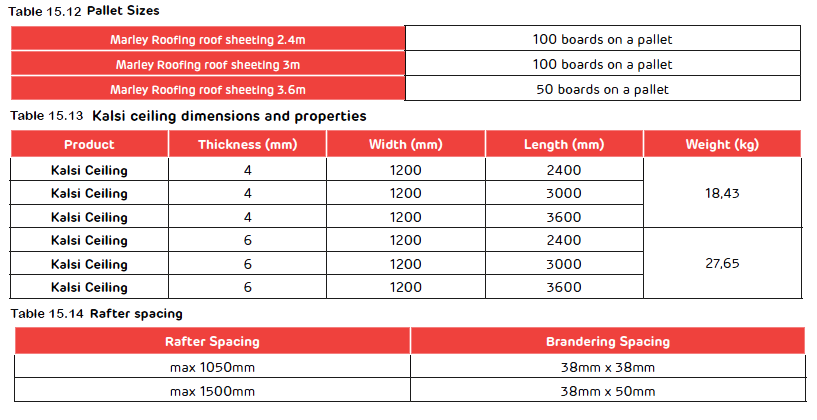

Concrete roof tiles are a common and cost effective form of roof covering. Concrete roof tiles consist of a mix of cementitious materials, such as Portland cement, sand, hydraulic cements, fly ash, pozzolans, fine aggregates and pigments, producing a durable lightweight tile that is fire resistant. Some are pigmented in the mix process known as ‘through colour’, others are coated after moulding.

Concrete roof tiles are manufactured in an extensive range of profiles, colours and finishes (finishes will vary from one manufacturer to another) which enhance the visual appearance of any roof and provide designers with a wide scope for expression.

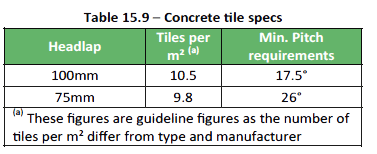

Truss and rafter centres when using concrete roof tiles are spaced to a maximum of 760mm using 38 x 38mm battens – refer Standards LL3.6.

Underlay – a suitable underlay is in all cases recommended. Modern practice has demonstrated that the underlay is a fundamental part of a tiled roof at pitches below 26° and for pitches above 45°, and at all pitches in exposed and coastal areas. (See underlays later in this section for more information)

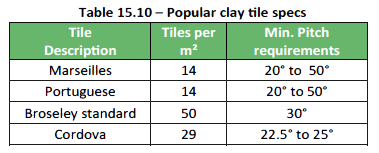

Clay (Class B)

Clay roof tiles enhance warmth and character to a building with permanent colour which weather and age over time, but never fade. Clay roof tiles are natural and durable which elegantly enhances the appearance of roofs, not only withstanding the elements, but actually improving with age from exposure.

Clay roof tiles are available in the ever-popular Broseley, Constantia & Cordova as well as the cost effective Portuguese and Marseilles. They are available from various different manufacturers in South Africa, in various colours like terracotta and multi flashed colours. Various bonds are used when laying different types of clay tiles, from; Straight bond or mock interlocking, broken bond, flat and semi-circular over under; the over-tile and under-tile are of roughly the same shape, the under-tile being larger; these tiles form a beautiful roof which is flexible in both sidelap and headlap.Truss and rafter centres when using clay roof tiles are the same as that of concrete roof tiles.

Clay cover tiles are usually used to cover IBR or Brownbuilt roof sheeting, to provide an attractive covering when low roof pitches are required. They can also provide thermal insulation and acoustic benefits. In certain instances it is required that IBR roof sheeting be covered with a cover tile by local authorities.

The truss and rafter centres when using cover tiles over sheeted roofing will reduce from the maximum of 1 400mm as directed by the cover tile manufacturer.

Pressed Metal (Class C)

Pressed metal roof tiles are strong and light weight which significantly reduces the quantity of timber required in the support structure and provides easy installation. They allow for ease of delivery and don’t require large trucks to transport them, making this a popular roof covering in remote lying areas. A further advantage being steel-based, no breakages occur during transit or storage on site.

Metal roof tiles come in different profiles and finished with either a standard acrylic coating or a textured coating and available in various colours and are also manufactured from different materials.

Due to their lightweight attributes, tiles are the ideal application

in the re-roofing market where they can be laid over the existing

roof without removing the old roofing material. Truss and rafter centres when using pressed metal tiles are spaced to a maximum of 1 050mm using 38 x 38mm battens – refer Standards LL3.6. Pressed metal tiles can be used without underlay on roof pitches between 15° and 45°; and with underlay with pitches from 10° to 15°.

Sheeted Roofing Systems

Sheeted roofing systems come in various different profiles, e.g. corrugated, IBR and folded steel. And manufactured from numerous different types of material to suit specific applications, all having certain advantages and unique properties with metal sheeting being the most commonly used.

Metal (Class A)

Metal Roof sheeting is available in a wide variety of profiles, thicknesses and types of material and coatings. Usually all roof sheeting materials are manufactured from hot-dipped galvanized steel and fall within internationally accepted specifications and tolerances.

Other types of material are manufactured like Supergalm which is an aluminium zinc alloy coated steel and Zincalume® a composite of aluminium and zinc. Typical types of material include; Commercial quality, high tensile and econogalv, while types of coatings include Chromadek. There is a variety of sheeted roof systems designed for larger type commercial buildings like shopping centres and industrial buildings known as ‘concealed fixing’ or ‘standing seam’ roof systems and are quite different to ‘exposed fixing’ roof sheets used for smaller type buildings and residential buildings. We have concentrated more on the pierced/exposed fixing systems used in residential building projects and only provide a brief overview of concealed fixing systems.

Pierced/exposed fixing

IBR and Widespan sheets must be laid with one corrugation and corrugated sheets with one and a half corrugations, side lap with the narrow flute uppermost and should be fixed through the crests of alternate flutes to purlins – see figures on next page (all fixing holes should be drilled and not punched).

Truss and rafter centres when using metal roof sheeting are spaced to a maximum of 1 400mm using 76 x 50mm purlins – refer Standards LL3.6.

IBR

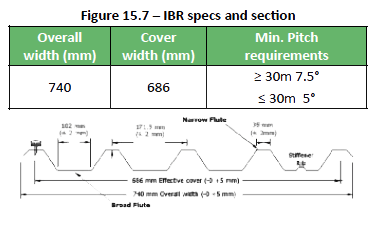

The name IBR is abbreviated from ‘Inverted Box rib’ and has become a household name in the South African building industry. The deep, broad flute design offers excellent drainage characteristics combined with optimum weight versus load/span capabilities.IBR sheeting has a square fluted profile usually with an effective covering width of 686mm designed for use as side cladding or roofing material in commercial, industrial and domestic applications.

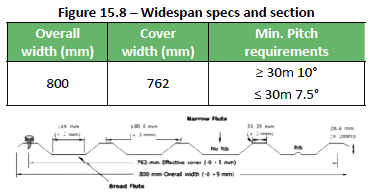

Widespan is a roofing and cladding profile designed to provide an economic alternative to deeper Box rib profiles without losing the aesthetic appeal of a square fluted sheet profile. The widespan profile offers greater spans and lower roof pitches than corrugated sheeting but provides the same covering width, being 762mm.

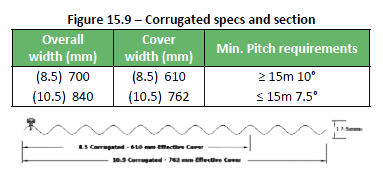

Corrugated (iron) is the traditional and familiar S-Rib profile for roofing and cladding applications. It is the oldest and most commonly used roofing profile because it is easy to handle, has excellent fixing properties and commensurate strength. The S-Rib is derived from the sinus curve and offers strong structural properties. The 8.5/76 represents 8.5 corrugations over the width of the sheet and the 76 refers to the distance in millimeters between two consecutive curves. The overall width of a traditional 8.5 corrugated sheet is 700mm and a 10.5 corrugated sheet is 840mm.

Concealed fixing is where a clip or special cleat is fixed to the purlin which securely holds the sheets in position and usually lock-in both the sidelap and centre ribs of the sheet; or where the cleat fastens to the purlin and folds over the flanges of the sheet and a cap snaps over this assembly. The main advantage of this type of roof system over others is the water-tightness achieved with very long spans at low pitches. Another advantage with concealed fixing (standingseam) is corrosion and failure at fixing points is eliminated. Brownbuilt metal sections pioneered the manufacture of concealed/secret fix roof profiles in SA with their “Brownbuilt” profile. Today other types of profiles are available and manufactured by a number of different manufacturers.

Fibre cement roofing sheets essentially consist of an inorganic hydraulic binder or calcium silicate formed by a chemical reaction of a siliceous and a calcareous material, reinforced by natural synthetic organic fibres. The sheets are supplied in their natural grey colour and can be painted (where required) with a 100% acrylic PVA after installation. Tinted sheets using a ultra-violet resistant pigment and branded as ‘Vineyard’ sheets are also available and recommended for Tuscan roofs where they are used as underlay for clay tiles.

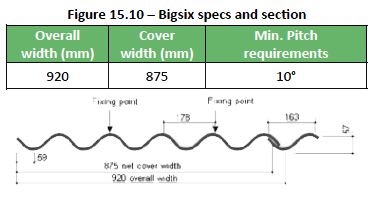

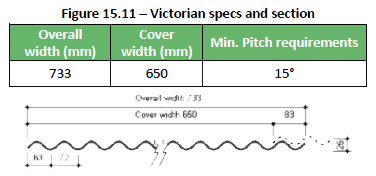

Fibre cement roof sheeting is available in two basic profiles;

- Bigsix and Victorian, which have been used in the South African building Industry for roofing applications and side cladding for decades.

- Bigsix corrugated sheets are durable and lightweight that can be used in all sectors of the building industry for roofing and side cladding.

The Victorian sheet is a popular profile and it has been designed to recreate the appearance and character of a traditional Victorian style roof and with its reduced dimensions and mass, makes handling and laying relatively easy. Victorian sheets are particularly suitable for coastal areas where corrosive conditions prevent the use of many other products.

Onduline is an extremely tough lightweight corrugated roofing and wall cladding material manufactured from bitumensaturated organic fibres under intense pressure and heat. It is flexible, economical and virtually indestructible. It provides a high degree of weather protection and thermal insulation- even in the most extreme climatic conditions. Colour stability is also ensured through a unique pigmentation process which “stains” the colour into the sheet.

- Needs virtually no maintenance

- High insulation and sound absorbency values

- Cannot rust or become brittle

- Rot and fungi resistant.

- Colour impregnation minimizes colour loss

- It is impact resistant and easy to handle.

- Easy to cut, shape and fix

Translucent (Class A)

Translucent or GRP (Glassfibre reinforced Polyester) sheeting is manufactured using UV stabilised unsaturated polyester resin and glass fibre reinforcement material. The weathering surface is covered with a highly UV stabilised gelcoat layer. This new generation technology offers superior weathering characteristics to conventional methods of surface protection in the GRP sheeting industry.

GRP products are specifically designed to withstand the harsh South African climatic conditions and a range of colours are manufactured, with the more popular being clear, white (opal 50), green and blue. All the generally used profile shapes, to match those of other roofing and cladding materials are usually manufactured.

Roof Slates

Slates can be described as any rectangular sheet of roofing material, whether of natural slate, stone, cast stone, fibre cement, or metal.

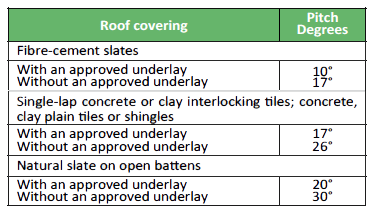

Fibre Cement (Class B)

Fibre cement roofing slates essentially consist of an inorganic hydraulic binder or calcium silicate formed by a chemical reaction of a siliceous and a calcareous material, reinforced by natural synthetic organic fibres. Fibre cement roof slates offer designers and specifier’s an alternative to other slates with a modern clean look and are available in a number of bright colours including white.

Fibre cement roof slates are designed for a minimum roof pitch of 10° using and underlay and 17° without and underlay and in high wind areas the slates may no longer provide a waterproof covering and a waterproof underlay must be installed. It is however important to be aware of the fact that any distortion or unevenness in the roof structure and/or battens will reflect in the final appearance of the application. Time spent to ensure that the structure and battens are accurate and sound is therefore a small investment in the process of achieving an excellent result.

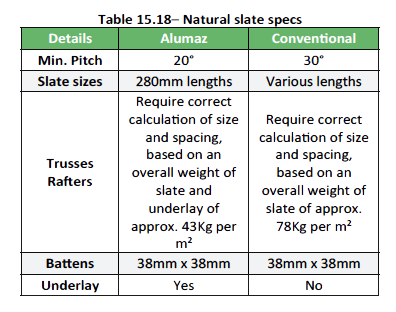

Natural Slate (Class B)

Slate is commonly described as a dark grey natural stone made up of many thin layers which can be split (riven) into thin sheets, then cut to size to create tiles. Slate is a heavy material and the roof structure must be designed to carry the weight – see Table 15.18. Slates are fire resistant and have a long life but are more costly than most other roofing materials.

Marley Roofing’s Fibre Cement Roof Sheets

Features and Benefits of Marley Roofing’s P75 Fibre Cement Roof Sheets:

- The product is non-combustible, rated A1

- The product causes minimal interference with radio wave transmissions

- Noise resistant

- Easy to install with normal tools

- Corrosion resistant

- Environmentally friendly – no harmful substances escape into the environment during production

- ASBESTOS FREE – sheets are made of concrete, limestone, amorphous silicon dioxide, cellulose, water, mineral additives and synthetic fibres (PVA)

- The product is “breathing”, enhancing ventilation and durability, and resisting condensation

- Long lasting, weather resistant and durable

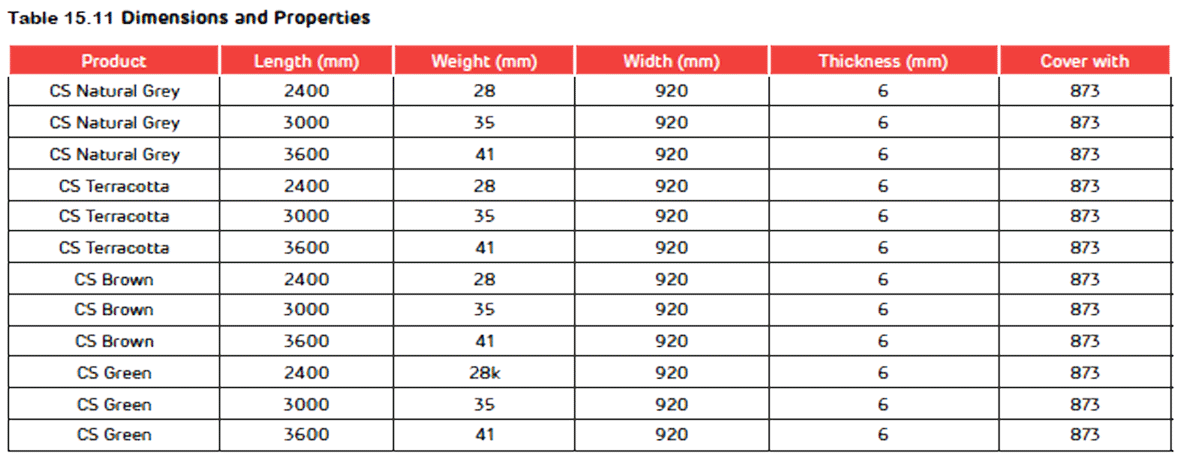

Dimensions and Properties

Refer to Table 11.49.

Standard Colours

Refer to Fig 11.12.

Fixing Accessories

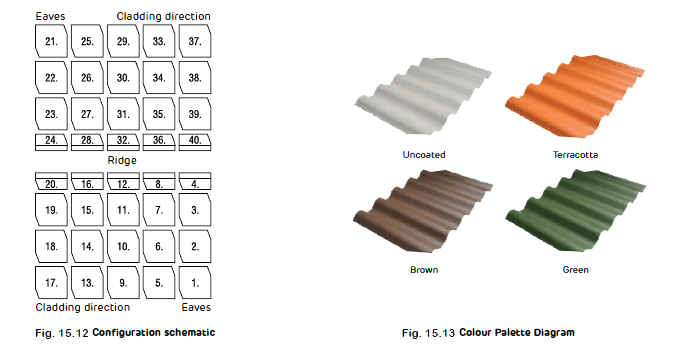

Wood: Pozigrip screw with PVC washer (dimensions: 6.3mmx120mm)

Steel: Hook bolt and nuts – length determined by depth of steel purlin (+90mm)

- Minimum pitch: 10 degrees

- Overlaps must be mitred

- Differences in height of overlays can result in roof leakages – to avoid this, two sheets are cut (mitred)

- Sheets are laid from right to left, and from bottom to top (for high wind areas, consult a structural engineer)

- According to the right-to-left cladding approach, the upper right and lower left edges must be cut

- Sheets can be cut with an angle grinder fitted with a masonry or diamond blade

- It is recommended that a 5-10mm gap be left between the upper right and bottom left sheets

- After cladding the upper left sheet, roof cladding should appear smooth

- Purlin size and spacing will be determined by the roof truss manufacturer (pitch, rafter spacing and clear span determine purlin space, however the minimum specified is 50x70mm wood with rafters 800mm apart and a clear span of max. 1400mm)

- Holes must be drilled not punched – drilled holes should be 2mm larger than the screw/bolt to allow for movement

- All fixing should be at least 25mm away from the edge of the sheets, and only in the crowns

- Do not exceed more than 300mm on the wall overhang and 150mm on the gable overhang

- The substructure must be leveled and squared out prior to installation for best results

Storage and handling

Storing sheets:

- When handled, sheets must be lifted at both ends

- Sheets must be stored in a covered room, away from rainfall

- Sheets must be stored on a dry, smooth and stable platform

- Maximum pallet stack: 2

Pallet Sizes

Refer to Table 11.50.

Handling sheets:

NOTE: Although Marley Roofing’s P75 FC Roof Sheets are fitted with security strips that can prevent a person from falling through the roof during roof maintenance works, it is recommended that duckboards are used as walking areas to avoid damage to sheets and injury to workers as per legislative requirements.

- Recommended Safety, Health and Environmental (SHE) regulations should be observed

- At no point should an area that has already been laid be used as staging for the next area

- Appropriate non-slip shoes should be worn by workers during roof maintenance installation

Marley KALSI®

Features and Benefits of Kalsi FIbre Cement Boards

- 100% ASBESTOS FREE

- Resistant to rot, termites and rodents

- Impact resistantancy on 9mm and 12mm boards

- Accepts most aesthetic and architectural finishes

- Moisture and humidity resistant

- Non-combustible

- Dimensionally stable

- Easy to install and handle

- Different board thicknesses available allowing for flexibility in use

Kalsi Ceiling

Dimensions and Properties

Refer to Table 11.51.

Installation Guidelines

Considerations:

- 4mm Ceiling boards are serrated (nail-up) and not suitable for plaster skimming

- 6mm Ceiling boards are ideal for exterior ceiling, soffits, car parks, laundries, bathroom, laboratories, etc.

- 6mm Ceiling boards are screw-up (brass wood screw, countersunk) – suitable for plaster skimming

- Use a sharp object to cut the surface of the board

- Hold board firmly and snap off

- Use H-Profile strips between boards (4mm or 6mm metal strips)

- Use one H-Profile strip per Kalsi ceiling board

Rafter Spacing

Refer to Table 11.52.

Refer to Table 11.53.

Fixing Accessories

32mm x 2.5mm serrated ceiling nails must be placed 150mm away from the edges of the board OR 12mm x 40mm brass woodscrew with countersunk head

Dimensions and Properties

Refer to Table 11.54.

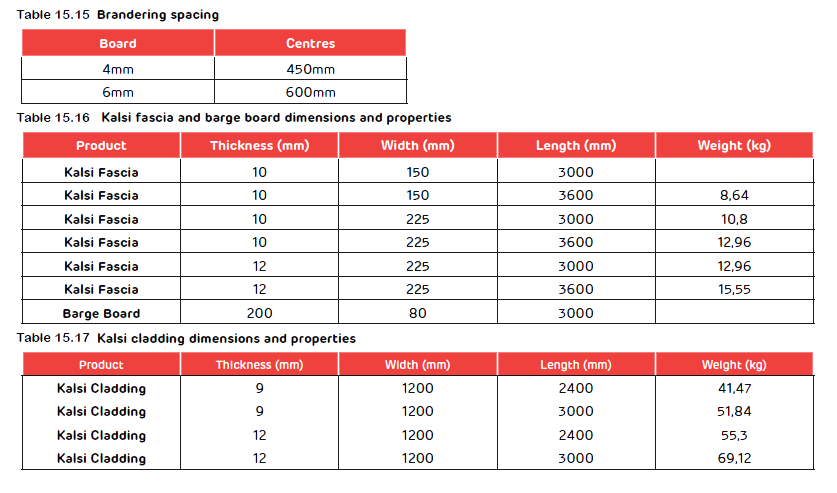

Kalsi Fascia and Barge Boards

Suitable for virtually any roof (includes tiles and sheeting), providing a functional finish while protecting the roof’s substructure.

Installation Guidelines

- Finishing is subject to the quality of the substructure (square and level)

- When the space between the rafters exceeds 900mm, a backing structure must be added

- The product can be nailed but fixings close to the edge must be pre-drilled (following the 25mm rule)

- Both wings of the barge board must be fixed in high wind and storm areas

- Hardened fluted steel nails or 12mm x 40mm brass wood screws with countersunk heads can be used for fixing

- Joint must not be made on fixing points but between them

- A support batten is needed if the span between rafters

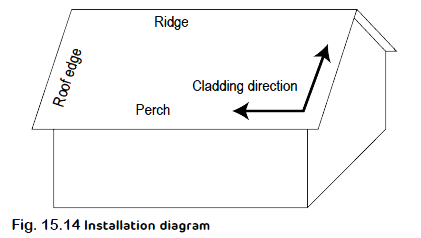

Kalsi Cladding

These boards can be used as a facade system or for cladding in a lightweight steel frame (LWSF) structure. Boards can be fixed as an expressed joint system or flush plastered.

Dimensions and Properties

Refer to Table 11.55.

- Fascia and barge boards can be joined by a cover strip or butt jointed (3mm gap sealed with specialised silicon)

- Boards can be plastered using specialist products and applicators

- A level and squared out substructure will ensure a quality finish

- Boards can be cut with an angle grinder fitted with a masonry cutting disc or a diamond blade.

- The max horizontal distance between the vertical supports should not exceed 610mm

- The max vertical distance between supporting brackets should not exceed 1500mm

- Thermal Conductivity for the cladding is 0.25 W/mk

- When boards are used in LWSF application, SANS 517 regulations must be observed

- – The cavity between two skins must be ventilated and insulated where applicable.

- – Sandwich specifications applies (Fire Proof, Acoustics, Thermal)

- – Board must be fixed every 300mm

- – Holes must be pre-drilled and countersunk

- – Hole must be drilled 2mm bigger than fixing shaft to allow movement in boards

All fibre cement products sold by Marley Roofing are warranted against defect in material and manufacturing processes. This warranty does not apply to defects resulting from any distributor or customer actions, such as mishandling, misapplication and improper installation. Our factories are also ISO 14001 certified, demonstrating our ongoing commitment to minimising waste, energy consumption, water consumption and pollution to the environment.

In addition to various international certifications, Marley Fibre Cement adheres to SABS specifications SANS 802 and SANS 10904.

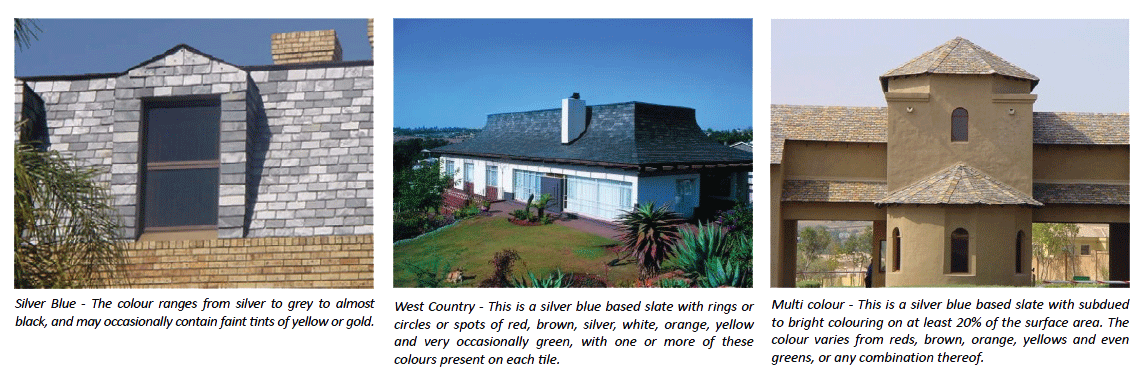

Natural slates are available in a number of different sizes and in a variety of colours usually originating out of the rock from which it was quarried; below are the more commonly used colours. See colours to the right. Slates are usually applied over solid sheathing covered with bitumen saturated roofing felt underlayment; commonly referred to as the Alumaz system. Slates can also be laid conventionally with no underlayment known as the conventional system.

Shingles

Shingles are made using an organic felt base saturated with bitumen and coated with a mineral-stabilized coating of bitumen on both sides. The exposed top side is coated with mineral granules. They are flexible, robust and lightweight and available in a range of colours.

Tile strips are available in a variety of styles, most common are rectangular and oval and they are laid on a boarded roof deck. Shingles can be laid on roof pitches of between 12° and 60°.

Roof Decks (flat roofs)

Construction methods for commonly used roof decks related to materials and types of construction are detailed in other sections in this book. A properly functioning roof depends on a structurally sound deck that is compatible with the roofing system and the installation of an approved waterproofing system.

Thatching

Thatch is classified as a class B roof covering and is probably the oldest type of roofing still used today. It is a popular and indigenous solution in particular areas where materials and skills are available and is the roof covering of choice in many African bush lodge designs and applications.

Thatch roofs should be constructed at a minimum angle/pitch of 45°. If good quality, clean, dry grass is used, the lifespan of the thatch will be increased (in general the top layer of thatch will need to be replaced and dressed every 12 to 15 years). Techniques, and to some extent materials, vary according to locality or region, and it is not possible in this section to provide more than an outline of what a thatch roof should contain.

- All changes of plane of the thatch surface; for example in valleys and over dormers, should be as gentle as possible.

- Thatch performs best on interrupted roofs and careful consideration should be given where to position chimneys or any other structure protruding from the roof.

- In thatching the interior finish forms an integral part of the overall roof design and needs to be discussed with the designer and building owner in the planning phase. As certain requirements could involve the services of a structural engineer e.g. Rafter/pole centres.

- Treatment of poles – normal dark poles or clear timber treatment.

- ither the same grass being used for the roof or a specific reed or thin bamboo.

Thatching is a natural insulator; cool in summer and retaining maximum internal heat in winter. Thatching also creates a relatively low cost means of additional living areas. The required pitch of a thatched roof allows this space to be used for a loft, by simply building a slab or suspended floor. The greatest disadvantage of thatch is the fire risk, although fire prevention in thatch has developed over the years and includes items like:

- Installation of a fire drenching system with either manual or automatic activation and is designed to deliver a thorough drenching to the roof exterior in the event of a threat of fire; installed into the ridge or capping.

- Dipping of the thatch into a fire proof solution before the thatch is laid. Or alternately spraying the roof with a fire retardant solution after the roof is complete.

- Using organic fibre simulated thatch, which is fire proof. Finally the installation of a lightening conductor is always advisable, however they can be seen as an eye sore and some insurance companies will cover your insurance needs without the installation of a lightening conductor.

Fire Protection

Outline

The designer of a roof of a building needs to know a lot about the conditions that will be imposed on that structure in service. Factors such as loading, environment and durability all have to be understood and assimilated into the design process, and considered in relation to behaviour in fire. For example, firewalls or fire stops that restrict the spread of fire in a roof assembly must extend continuously from a structure’s foundation to or through its roof.

If the fire wall stops at the roof, the roof assembly must then consist of non-combustible materials. The fire wall should be able to remain intact even if the structure on either side collapses due to fire damage.

The National Building Regulation’s fire protection standard – SANS 10400 Part T stipulates requirements for fire ratings and approved non-combustible materials; and contain content that is relevant to roofs and their fire protection – see some extracts below.

- 4.12.1.2 Where any combustible roof covering material, including thatch, shingles and bituminized felt on boarding is used and the plan area of such roof is more than 20m2, the distance between the building so covered and any boundary of the site on which such building is situated shall be not less than 4,5 m.

- 4.12.1.3 Where any roof covering includes individual, small areas of combustible material, the total area of which is not more than 5 % of the roof area, and where:

- a) No such individual area is more than 20m2, such roof covering shall not be considered a combustible roof covering, provided that

- Where the slope of the roof does not exceed 60° there shall be a minimum distance of 1m between any two such areas, and

- Where the slope of the roof exceeds 60° there shall be a minimum distance of 1m measured horizontally and 3m measured along the slope of such roof between any two such areas.

- b) Any such individual area exceeds 20m2 in a roof and might constitute an element of danger to the public; such material shall be permitted only where it is the subject of a rational assessment regarding its use and application.

- a) No such individual area is more than 20m2, such roof covering shall not be considered a combustible roof covering, provided that

- 4.12.1.6 Where roof space is formed between any ceiling and any roof covering, such space shall be divided by means of non-combustible fire stops with a stability and integrity rating of at least 20 min into areas of not more than 500m2. The distance between such fire stops shall be not more than 30m, provided that this requirement shall not apply where such roof space and the room below are protected by a fixed automatic fire-fighting system and smoke control system in accordance with 4.4.2. If any combustible materials are installed in such roof space, such as combustible insulation, then the area for non-combustible fire stops shall be not more than 250m2 and the distance between such fire stops shall not be more than 20m.

- 4.12.2.1 The safety distances derived from 4.2 shall, notwithstanding the occupancy classes (see section 3 – Building Drawings – for this table), be based on a high fire load where the thatch is untreated and value A in the formula will be based on the facade area of the roof. Where the thatch is treated with an acceptable fire-retardant system, the safety distances shall be based on the following fire loads:

- a) test result A – low fire load

- b) test result B – medium fire load

- c) test result C – high fire load

Note: A test result C is equivalent to an untreated roof.

-

4.12.2.2 Notwithstanding the requirements of 4.12.1, a thatched lapa that has a roof plan area of less than 20m2, that is free standing and not attached to any other building shall not be erected closer than

- a) 1,0m to any boundary, and

- b) the safety distance from any building derived from 4.2, unless a free-standing masonry or concrete wall that has a height greater then 0,3m above the bottom line of the roof and which extends at least 1,0m on either side of the lapa is erected.

Note: Safety distances or fire separation specifies the distance between adjacent buildings; it is used to reduce the risk of fire spreading from one building to another.

- 4.12.2.3 A competent person (fire engineering) shall perform a rational assessment to determine the acceptability of erecting a lapa against an existing building.

- 4.12.2.4 Buildings and lapas with a thatched roof plan area greater than 300m2 or which are closer than the greater of 4,5 m to any boundary and the safety distances from an existing building derived from 4.2, shall be provided with additional fire protection systems (post-treated on both sides, pretreated as a permanent system or any other system) that are acceptable in relation to the actual roofing system that is to be used, and retreated and maintained at the intervals as indicated by the manufacturer of such systems.

Underlays

Outline

An underlay can be described as any layer or sheet material layed under another material. Typically a roofing underlay is a weather-proofing membrane, which prevents moisture, wind and dust entering the roof space. Roofing underlays can at times be confused with insulation, although in some cases they can perform dual functions, for example alububble® where the underlay is an effective water vapour barrier under roof tiles or roof sheeting and at the same time insulates the roof. Underlays for supported sheeting applications like shingles are usually of inodorous felt while tiles and slates are underlain with plastic sheet known as undertile plastic except on low pitches (typically in natural slate applications) bitumen felt is used.

The National Building Regulations covers various types of roof coverings and pitches where underlays must be used; they all fall under class B roof coverings as described in the table below.

Discussed ahead are the two types of underlay most often used in roofing applications; plastic and felt. For other underlays used for insulation properties, see thermal Insulation.

Plastic Membranes

Plastic underlays are a polyethylene membrane that has been specially formulated for use under roof tiles and slates, usually (250μm – micron) in thickness and made in rolls of 1.5 x 30 m and must be SABS approved.

The membrane is designed to prevent moisture from warm damp air reaching and condensing on ceiling boards and other vulnerable points in the building fabric. It is also used for the prevention of draughts and dust penetration into the roof space through tiles and slates, and prevents damage to ceilings and rotting of timbers.

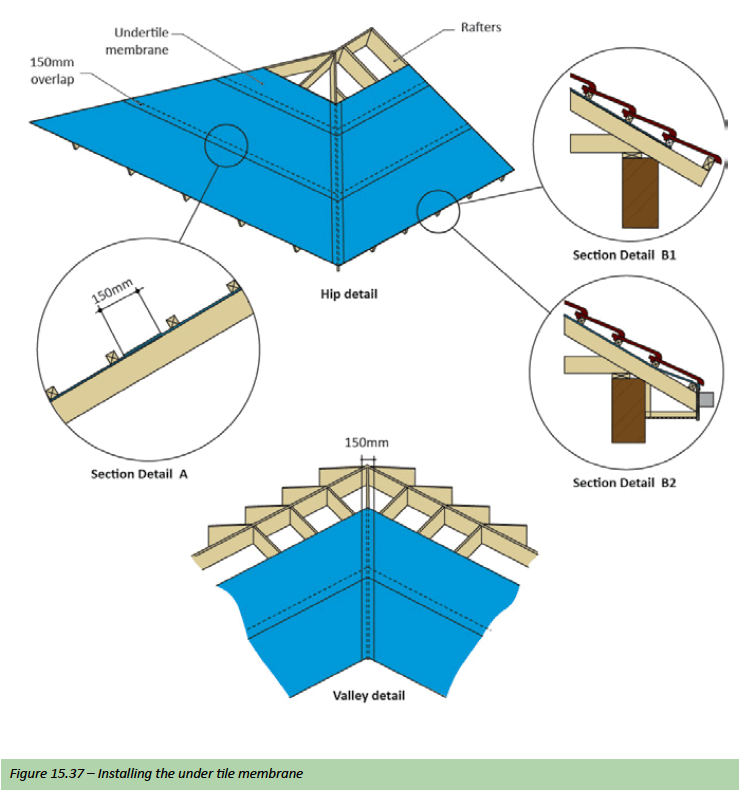

The underlay further prevents strong wind from lifting and ripping off roof tiles. The underlay must be fixed horizontally between rafters and battens with 150mm minimum overlaps and carried well into the gutters. Avoid allowing the underlay to sag and form water traps – particularly behind fascia boards. A strip of underlay, at least 600mm wide, must be placed at hips so as to overlap each side for its full length. A similar strip must be laid for the full length of each valley ensuring that the opposing slopes overlap the edges.

Felts

Felt underlays are a sheet made from cellulose fibres of organic materials such as kraft paper and glass fibres saturated with bitumen and coated with a layer of thin mixed asphalt and crushed gravel or sand which can be laminated with other materials like aluminium foil or polyethylene. Felts are usually supplied in rolls of 10m and 20 m x 450mm and 900mm wide. In natural slate roofing applications the felt underlay is typically faced over half its width with a heat laminated layer of aluminium foil, used as a waterproofing membrane which is long lasting and also prevents the ingress of dust.

Vapour barriers

Vapour barriers are a plastic or foil sheet that resists diffusion of moisture through the roof assembly and typically used in sheeted metal roofing applications to prevent moisture from penetrating other inaccessible building components and condensing as moisture on insulation and ceilings. If condensation occurs in a building it is both difficult and costly to eradicate so it is always recommended to take precautionary measures during construction and design. To avoid condensation in a roof, moist air must be prevented from contacting the underside of the sheeting.

Thermal Insulation

Outline

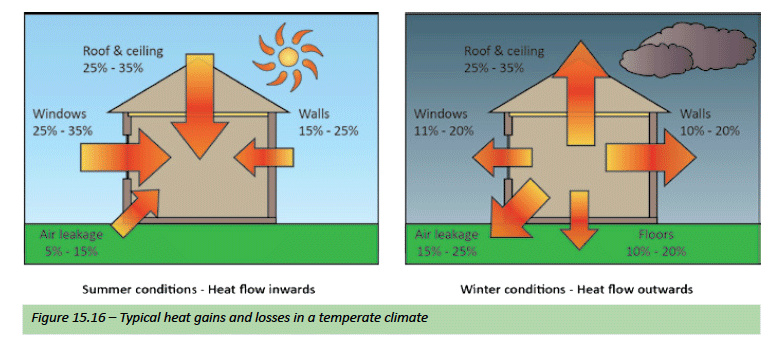

Thermal insulation acts as a barrier to heat flow and is essential in keeping a building or home warm in winter and cool in summer. A well-insulated and well-designed building or home will provide all year comfort. Climatic conditions will influence the appropriate level and type of insulation; which are covered in SANS 204 under Standards and in the “Insulation installation” section that follows. It is important to establish whether the Insulation will be predominantly needed to keep heat out (summer) or in (winter) or both. Insulation must cater for seasonal and daily variations in temperature. Ceilings and roof spaces account for 25 to 35% of winter heat loss and must be well insulated. To prevent heat loss, locate most of the insulation next to the ceiling as this is where the greatest temperature control is required.

Choosing Insulation

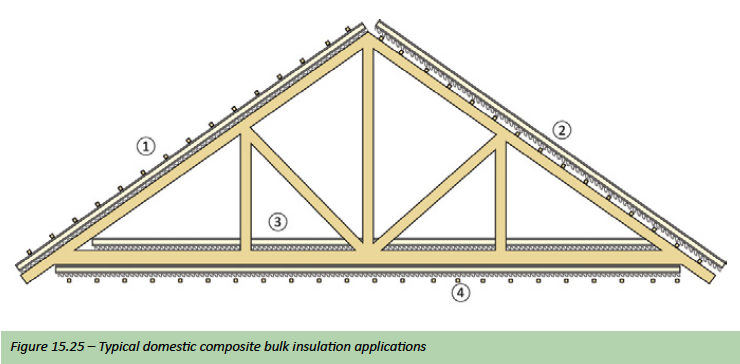

Insulation products come in two main categories – bulk (cellular) and reflective. Examples of Bulk insulation are – Mats e.g. Aerolite; Loose fill e.g. Thermguard; and Insulating boards e.g. Isoboard (polystyrene). They have many tiny air or gas bubbles, which reduce conductivity and commonly make them lightweight. Whereas reflective insulation, such as aluminium foils and low-emissivity coatings, reduces heat loss or gain by radiation. These are sometimes combined into a composite material. There are many different products available, like alububble®.

See next sub-heading ‘Insulation types and Properties’

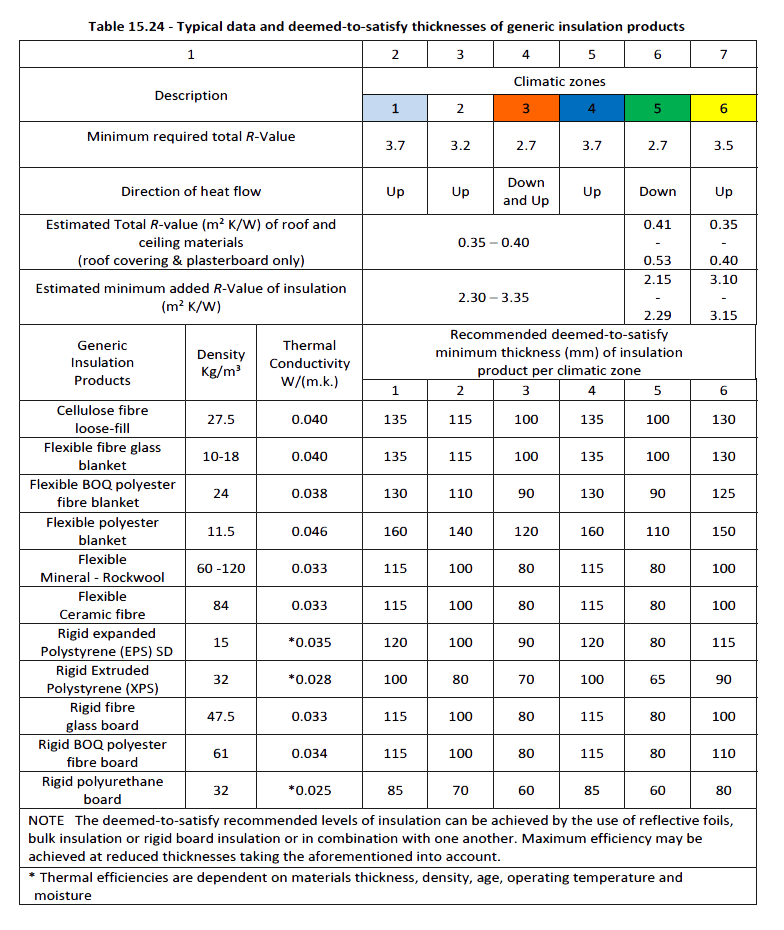

To compare the insulating ability of the products available look at their R-value, this measures resistance to heat flow – the higher the R-value the higher the level of insulation.

Note: Products with the same R-value will provide the same insulating performance only if installed as specified.

R-values can differ depending on the direction of heat flow through the product. The difference is generally marginal for ‘bulk’ insulation but can be pronounced for ‘reflective’ insulation. Some products must be installed professionally while others can be defined as DIY – some types of insulation require the use of masks and protective clothing. Ensure products chosen or specified suit the particular application and will fit within the space available. The appropriate mass or amount of insulation depends on a number of factors like climate, building type and size, and whether the building is naturally or mechanically ventilated. The National Building regulations – SANS 10400: PART XA sets out minimum requirements – see Standards.

Insulation Types and Properties

Bulk insulation

Bulk insulation mainly resists the transfer of conducted and convected heat, relying on pockets of trapped air within its structure. Its thermal resistance is essentially the same regardless of the direction of heat flow through it. Bulk insulation includes materials such as glasswool, wool, cellulose fibre, polyester and polystyrene. All products come with one material R-value for a given thickness.

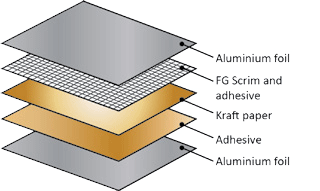

Reflective insulation

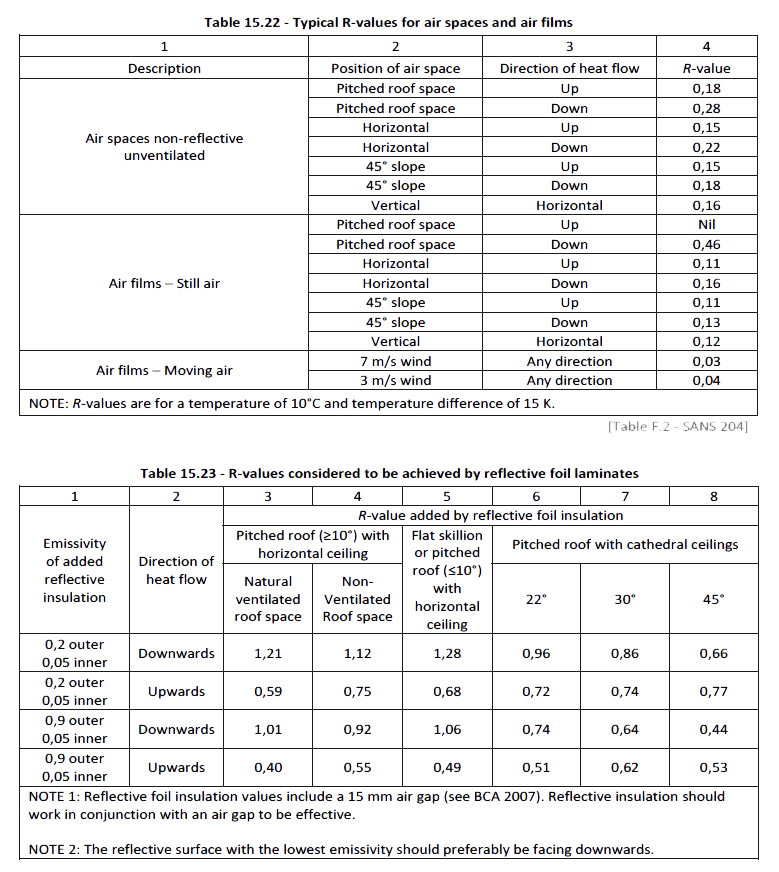

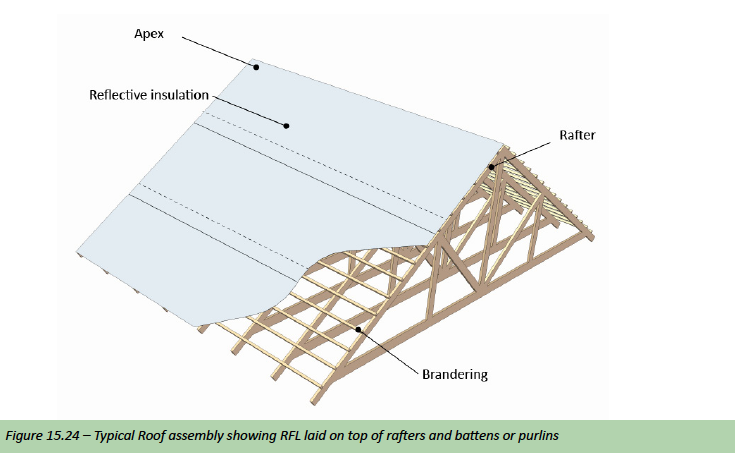

Reflective insulation mainly resists radiant heat flow due to its high reflectivity and low emissivity (ability to re-radiate heat). It relies on the presence of an air layer of at least 25mm next to the shiny surface. The thermal resistance of reflective insulation varies with the direction of heat flow through it. Reflective insulation is usually shiny aluminium foil laminated onto Kraft paper and or plastic (polyethylene or polypropylene) and reinforced using a scrim, all bonded together and available as sheets (sarking). Together these products are commonly known as reflective foil laminates or RFLs – See following example.

Dust settling on the reflective surface will greatly reduce performance. Face reflective surfaces downwards or keep them vertical. The antiglare surface of single sided RFLs should always face up. The Total R-values for reflective insulation are supplied as up and down values. Total values depend on where and how the reflective insulation is installed. Ensure system values provided by the manufacturer relate to your particular installation situation – See thermal resistance of systems below. Composite bulk and reflective materials are available that combine some features of both types.

Thermal Resistance of Systems

Manufacturers of bulk insulation products typically quote the thermal resistance, R-value and thermal conductivity, k-value and thickness, of their products. Confusion arises when suppliers of reflective insulation quote thermal resistance values which are inclusive of air gaps. Such thermal resistance values are in fact the resistance of a total system and cannot be compared to individual product R-values. RFLs, e.g. foil laminates, are typically very thin with high thermal conductivities, and thus have a very poor thermal resistance. For this reason, radiant barriers should always quote an associated air gap.

A word of caution must be sounded with respect to air gaps. Although it is acknowledged that static air is a very good insulator owing to its very low thermal conductivity, it must be borne in mind that thermal gradients can induce natural convection, in which case convection becomes the main mechanism of heat transfer and not conduction. When this takes place, the thermal performance of air gaps is drastically reduced. Many published system thermal resistances for reflective insulation ‘systems’ are based on ‘trapped’ air gaps above and below the barrier, which is sometimes impossible to achieve in practical installations. Thus thermal resistance values, inclusive of air gaps, determined under ideal, experimental conditions, tend to overstate the performance of the system. It is recommended that the total thermal resistance of systems be calculated on the basis of internationally accepted standards and procedures to ensure that the required thermal performance is achieved and can be guaranteed.

Where to Install Insulation

Firstly it is important to understand that roofs and ceilings work in conjunction when it comes to insulation and for this reason are referred to as roof assemblies in building standards.

- Install insulation under the roofing material to reduce radiant heat gain.

- Install insulation above the ceiling to reduce heat gain and loss. In most cases ceiling insulation is installed between the joists. (See: Insulation Installation).

- Install insulation in hot climates under veranda roofs where outdoor living spaces are used extensively, to reduce radiant heat gain. Heat build-up under verandas not only affects the space below but can affect conditions inside the house.

- Install insulation in bulkheads (sections between ceilings of different heights) to the same level as the ceiling, as they are subjected to the same temperature extremes..

Note: One can save up to 45% on heating and cooling energy with correctly specified and installed roof and ceiling insulation.

Improving Insulation in Existing Buildings

Many existing buildings were built before even basic thermal insulation provisions were introduced and many before any standards were considered or discussed. There are considerable opportunities for improving energy efficiency in existing buildings. These opportunities depend upon how individual buildings are constructed both for the practical difficulty of carrying out the improvements and their cost effectiveness.

Insulation can be added to existing buildings with varying effectiveness and cost depending on the construction type and where the insulation is being placed.

It is usually easy to insulate pitched roofs with accessible roof spaces, giving highly cost effective results. Flat roofs are more difficult to insulate as the space between ceiling and roof covering is often inaccessible and where the internal ceiling or external roof sheeting must be removed before insulation can be installed; which in most cases would not be cost effective. Although, it is possible to apply special coatings on the roof covering which does then provide better insulation. In so far as concrete slabs are concerned inverted insulation can be installed, which could be more cost effective when the waterproofing needs to me renewed.

Standards

Extracts from SANS 10400XA

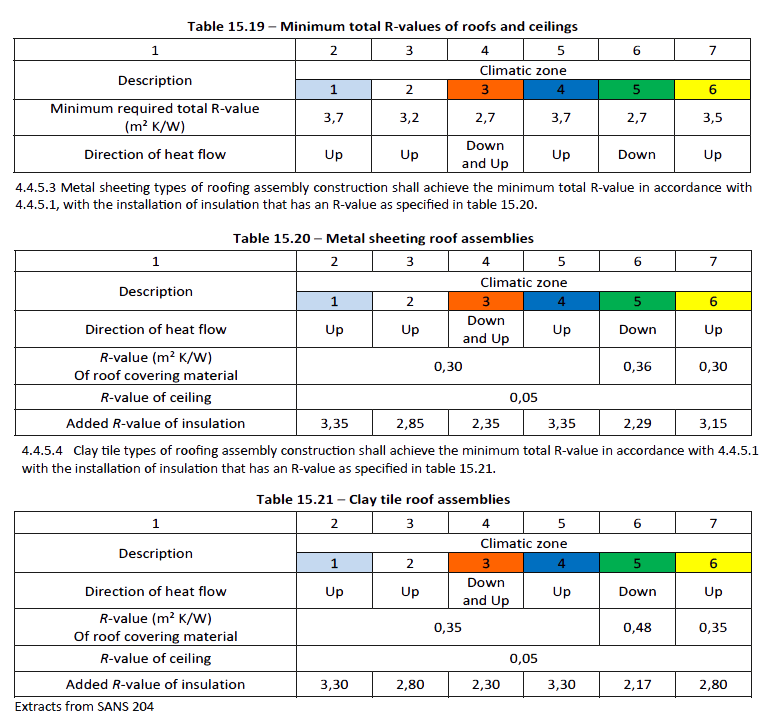

- 4.4.5 Roof assemblies

- 4.4.5.1 A roof assembly shall achieve the minimum total R-value specified in table 15.19 for the direction of heat flow.

- 4.4.5.2 A roof assembly that has metal sheet roofing fixed to metal purlins, metal rafters or metal battens shall have a thermal break consisting of a material with an R-value of not less than 0,2 installed between the metal sheet roofing and its supporting member.

- 4.4.6.2 Thermal insulation

Insulation shall comply with minimum required R-values and be installed so that it:- a) Abuts or overlaps adjoining insulation, or is sealed,

- b) Forms a continuous barrier with ceilings, walls, bulkheads or floors that contribute to the thermal barrier, and

- c) Does not affect the safe or effective operation of any services, installation, equipment or fittings.

- a) Non-combustible when tested in accordance with SANS 10177-5, and may be installed in all occupancy classes; or

- b) Classified as combustible according to SANS 10177-5, shall be tested and classified in accordance to SANS 428 protocol for its use and application.

4.4.6.2.3 Reflective insulation shall be installed and supported:

- a) With the necessary airspace in accordance with Table 15.22 in order to achieve the required R-value between a reflective side of the reflective insulation and a building lining or cladding,

- b) With the reflective insulation tightly fitted and taped against any penetration, door or window opening, and

- c) With each adjoining sheet of roll membrane being

- 1) Overlapped by not less than 100 mm, or

- 2) Taped together.

4.4.6.2.4 Bulk insulation shall be installed so that

- a) it maintains its position and thickness, other than where it crosses roof battens, water pipes or electrical cabling, and

- b) In ceilings, it overlaps the wall member by not less than 50 mm or is tightly fitted against a wall where there is no insulation in the wall.

Note: See table 15.24 regarding typical R-values for roof/ceiling construction and the resulting typical intervention insulation thicknesses.

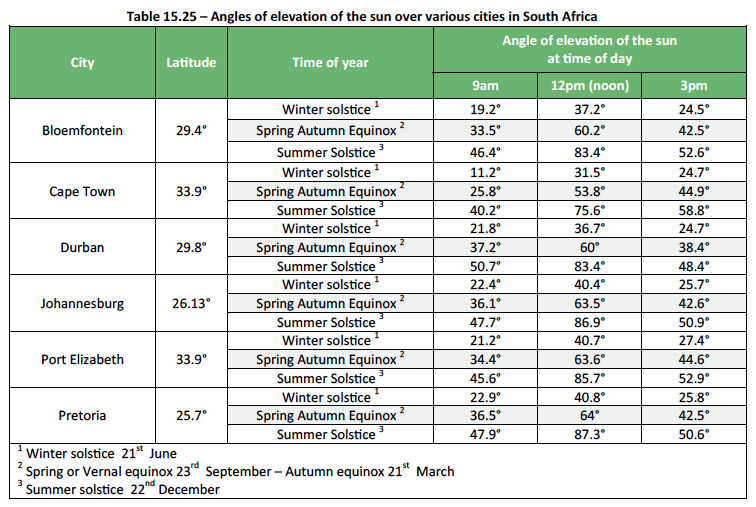

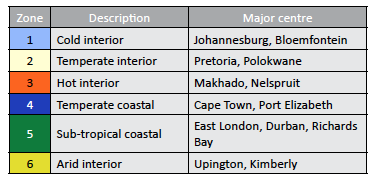

Climatic zone: The first fundamental matter that needs to be determined before applying the DTS provisions is the climatic zone in which the building is to be located. The climatic zone map of South Africa (see Foundation Section) shows diagrammatically the extent of each zone and the table detailing the applicable climatic zone for common locations. In this case, the applicable climatic zone for Cape Town is 4.

Insulation: Roofs in climatic zone 4 are required to achieve a minimum total R-value of 3,7 in the upwards direction (see table 15.19). A pitched tiled roof with a flat ceiling in climatic zone 4 achieves a total R-value of 0,35. This means that additional insulation that achieves a minimum R-value of 3,35 (3,7 to 0,35) in the upward direction is required to be installed in the roof. This can be achieved by installing bulk insulation or a combination of bulk and reflective insulation

Compression of bulk insulation: The R-value of bulk insulation is reduced if it is compressed. The allocated space for bulk insulation must therefore allow the insulation to be installed so that it maintains its correct thickness. This is particularly relevant to wall and cathedral ceiling framing whose members can only accommodate a limited thickness of insulation. In some instances, larger framing members or thinner insulation material, such as polystyrene boards, may be necessary to ensure that the insulation achieves its required R-value.

Insulation Installation

As already established installing insulation can make a significant difference to the overall energy efficiency of a home or building. Roofs and ceilings or as referred to here and in the standard as a roof assembly are a very significant element in the consideration of energy efficiency of any home or building, more particularly when that building is single storeyed. All the components and materials of a roof and ceiling, and even the spaces between layers of the materials (cavities), contribute to the overall energy efficiency or thermal performance of a roof assembly. Installing roof and ceiling insulation can save up to 45 % on heating and cooling energy.

What follows in this section is to briefly describe how to install insulation showing different products and the different uses they have in their application in different roof construction and assemblies, also providing installation tips and typical solutions.

Pitched roofs with flat ceilings

This is the most common type of roof assembly and the easiest to insulate.

Roof

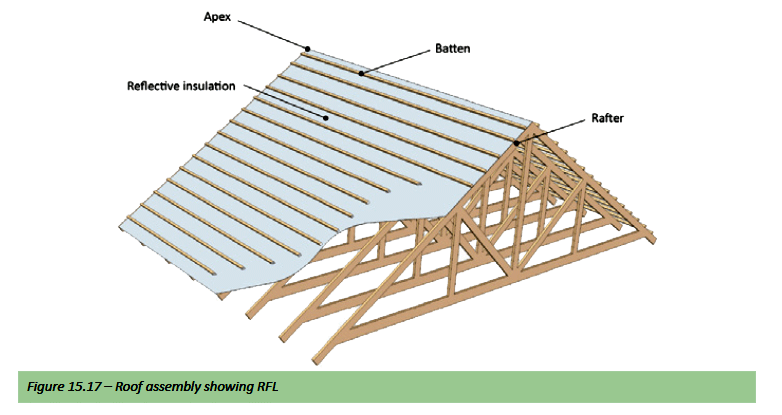

A layer of reflective foil laminate (RFL) is an effective barrier to radiant heat and as a vapour barrier. Reflective insulation gives excellent insulation performance for downward heat flow (summer heat gain), but only moderate performance for upward or horizontal heat flow (slowing heat losses in winter) and requires an air space between the foil and solid surfaces to achieve full insulation qualities. RFLs should be installed in conjunction with conventional bulk insulation, to achieve optimum energy efficiency.

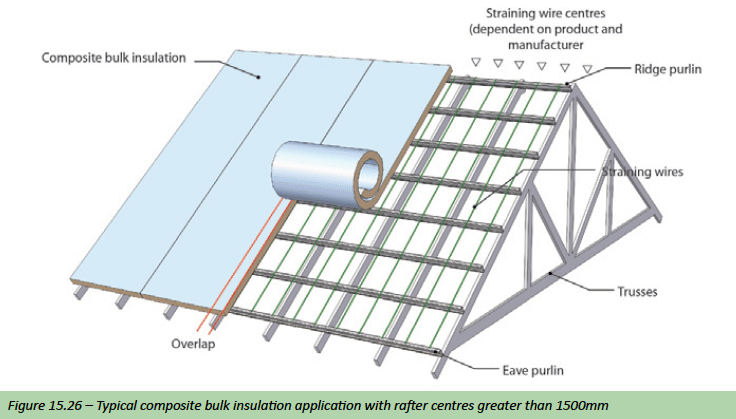

- Under steel sheeted roofs – (directly under the roofing material) over purlins or timber battens or straining wires as required, or

- Under tile or slate roofs – between the battens and the rafters i.e. under the timber batten, or

- In accordance with the manufacturer’s instructions

The most common method of installation in domestic applications is where the RFL is stapled with industrial staples to the top of the rafter (with timber trusses) before fixing of the batten or purlin. The insulation (RFL) material is then laid horizontally (gable to gable) commencing at the eaves an ensuring that subsequent sheets overlap the previous sheet by 100mm. With this method the RFL acts as both insulation and as a waterproofing membrane.See figure 15.17

A second layer of RFL (either sarking or foil batts) beneath the roof will increase resistance to radiant heat. This may be useful in hot climates. However, ensure that there is at least a 25mm gap between reflective surfaces.

Ceiling

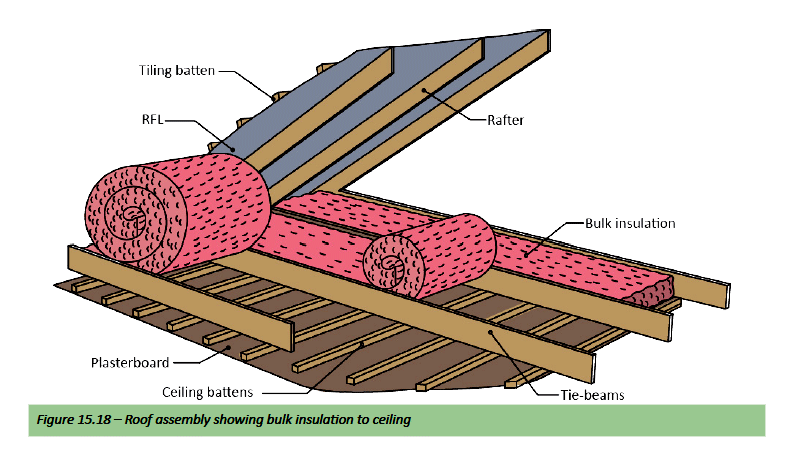

Place ceiling insulation between the joists. Suitable bulk insulation includes bulk batts, mats, cellulose loose fill and polystyrene boards. In colder climatic regions two layers of bulk insulation may be necessary to increase thermal performance, one between the rafters and the second on top. Other insulation types include flexible composite bulk and reflective materials which combine some features of both types; and can be installed in the same way as bulk insulation except that the reflective foil would determine its position i.e. facing downwards. See figure 15.18

Note: The National Building regulations Part XA (SANS10400XA) sets out minimum requirements for materials R-values for different climatic zones used in roof assemblies – refer Standards

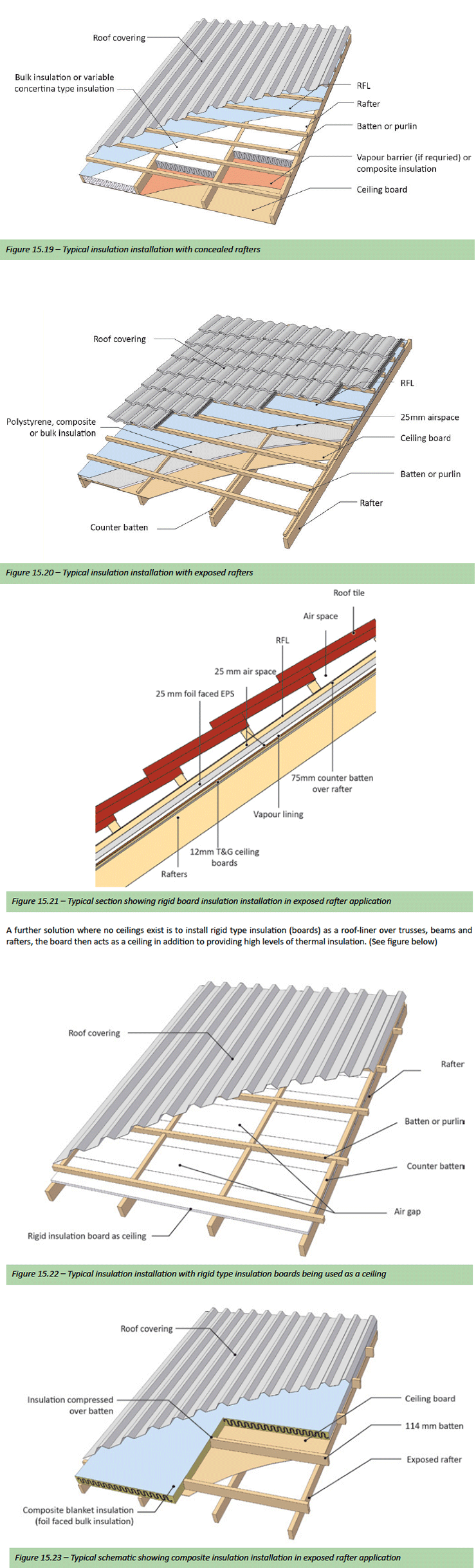

Ceilings that follow the roof line

These include sloping ceilings, cathedral ceilings, vaulted ceilings, and flat or skillion roofs, where there is no accessible roof space.

Roof

A layer of reflective foil laminate (RFL) is an effective barrier to radiant heat and as a vapour barrier. Reflective insulation gives excellent insulation performance for downward heat flow (summer heat gain), but only moderate performance for upward or horizontal heat flow (slowing heat losses in winter) and requires an air space between the foil and solid surfaces to achieve full insulation qualities. RFLs should be installed in conjunction with conventional bulk insulation, to achieve optimum energy efficiency.

- Under steel sheeted roofs – (directly under the roofing material) over purlins or timber battens or straining wires as required, or

- Under tile or slate roofs – between the battens and the rafters i.e. under the timber batten, or

- In accordance with the manufacturer’s instructions

Foil backed or faced blankets (composite insulation) can also be used (although they are primarily designed for application where no ceilings exist) where the outer jacket reflects heat and controls condensation under steel sheeted, fibrous cement and tiled roofs (acting as a vapour barrier); and where the bulk insulation provides thermal and acoustic insulation mainly to reduce the noise associated with metal roofing. When used for thermal insulation, compression of the blanket over the battens or purlins lowers the total R-value.

Ceiling

- The first step lies in the design – ceilings that follow the roof line require enough space to accommodate adequate insulation, including any necessary air gaps and where:

- Ceilings with concealed rafters are easier to insulate and should be considered in preference to ceilings with exposed rafters, and

- Ceilings with exposed rafters require insulation products with a higher R-value per unit thickness due to space limitations within the ceiling.

Consult the insulation manufacturer or installer about installation clearances. As a rough guide, minimum clearances (batten height) for ceilings with exposed rafters are:

- Rval 2.88 Flexible fibre glass (glasswool) blanket: 115mm

- Rval 2.0 polystyrene boards: 65mm

Suitable composite insulation for exposed rafter applications includes foil faced polystyrene boards (it is a lot easier to install); the minimum batten height should be 65mm to allow for two 25mm reflective air spaces either side of the boards where 25mm boards are being used. 25mm foil faced polystyrene boards and RFL insulation will give a total R-value of approximately 1.7 up, 2.9 down.

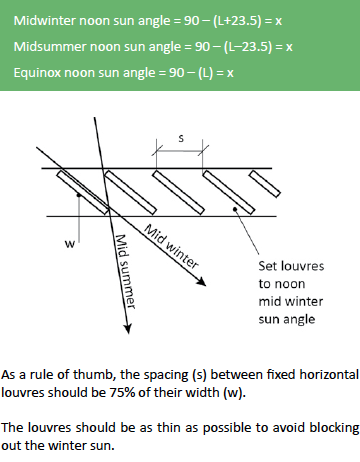

No Ceilings