Chapter 14

FORMWORK AND SCAFFOLDING

Formwork

Scaffolding

Scaffold Frames

Independant Scaffolding

Mobile Scaffolding

Concrete Forms

Formwork Design Guides

Slab Formwork

Wall Formwork

Universal Lightweight Formwork for Walls, Columns and Slabs

Formwork

Formwork is the term given to either temporary or permanent moulds into which concrete is poured, keeping it in place until it cures – such as for columns, beams or slabs. In terms of vertical surfaces, formwork can usually be taken down after a 24-hour period. With beams and slabs, props and forms are usually left in place until the concrete has gained sufficient strength (28 days) or removed and back propping is used for horizontal surfaces. Formwork must bear all loads put on it by concreting and be sturdy and grout-tight during compaction/vibration, particularly for direct finishes; referred to as the off shutter finish which comes in different grades/classes; (typically the concrete is found to have the texture of the material used for the shuttering and also the shape of the panel used).

Types of formwork

- Traditional timber formwork: The formwork is built on site out of timber. It is easy to produce but time consuming for larger structures, and it has quite a limited lifespan.

- Engineered/Modern Formwork systems: The formwork is built out of prefabricated modules with a steel frame and is made of a material with the required surface structure (steel, timber, etc.) where the contact surface between the concrete and formwork lies. The two major advantages of formwork systems, compared to traditional timber formwork, are speed of construction and lower life-cycle costs. These systems can be separated into two groups; Horizontal and Vertical.

- Stay-In-Place Formwork systems: The formwork is assembled on site, usually out of prefabricated Insulating Concrete Forms. The formwork stays in place after the concrete has cured. Other stay-in-place formwork is made out of prefabricated fibre-reinforced forms. These are usually used for columns and piers. The formwork stays in place after the concrete has cured and acts as axial and shear reinforcement, as well as serving to confine the concrete and prevent against environmental effects, such as corrosion and freeze-thaw cycles.

For the first two types, once the concrete has been poured into formwork and has set (or cured), the formwork is removed to expose the finished concrete. The removal ti me of the forms is dependent upon the strength needed to be achieved by the cured concrete. Release agents Chemical release agents are applied to mould and shutter surfaces prior to casting concrete, in order to achieve a clean and easier release of the shutter (formwork) from the concrete when stripping.

Scaffolding

Scaffolding is a temporary platform carried by a framework erected on site, to give access for trades like (bricklaying, plastering, and painting) and to carry materials. It is usually a modular frame system of metal or aluminium, although it could be made out of other materials. Scaffold staging or tower scaffolds are usually of steel or aluminium, either of a prefabricated frame type that clip together or of a tubular type joined with fittings,, for example a putlog coupler.

Scaffold boards or planks that form the working deck of a scaffold, must be strong enough to carry the materials and workers. They are either wooden planks and should be at least 228mm wide and 50mm thick and not be longer than approximately 4,8m with a maximum support distance of 2,2m; or steel planks which clip into the framework and are typically 228mm wide. Scaffolds are rarely independent structures. To ensure a constant and workable space between the structure and the scaffold, ties are used to link the two, which also ensures the scaffold remains sturdy.

- Steel builders trestles

- Scaffold frames

- Independent (purposely erected) scaffolding

- Mobile scaffolding

Steel builders trestles

A standard steel builders trestle can be used for almost every type of interior and external building activity up to about 2,4m (single storey buildings). It usually accommodates a four board working platform of approx. 1,0m wide, and is easily handled by one person and folds away for quick storage and transport. Trestles are usually available in the following heights:

- 800 – 1000mm extending to approx. 1800mm (Ideal for fitting, plastering and painting ceilings)

- 1200 – 1400mm extending to approx. 2000 – 2400mm (Ideal for brickwork and plastering)

Scaffold Frames

Independent Scaffolding

Mobile Scaffolding

Mobile scaffolding can be best described as any kind of speed framing or scaffold framing with rolling castors with a brake mechanism. The height of a mobile scaffold or tower should not exceed three times the smallest base dimensions i.e. if the smallest base width is 1.8m the height must not exceed 5.4m. When a mobile tower exceeds 6m in height it must be regarded as an independent scaffolding and where the same securing details

should be complied with. The castors will also need to be securely anchored to the ground to eliminate displacement.

NOTE: Safety is of utmost importance and any scaffold exceeding 3m in height should be inspected by a competent person or a structural or civil engineer, before any loading is placed on the scaffolding.

Concrete Forms

Concrete forms are engineered structures that are required to support loads such as fresh concrete, construction materials, equipment, workers, various impacts and sometimes wind.

Online formwork load monitor

The PERI Formwork Load Calculator supports the professional user in calculating the correct fresh concrete pressure in connection with the related pouring rate for selected PERI wall formwork systems. With this tool, the user obtains a very quick overview of the loads and deformations which leads to cost-effective utilization of the formwork system being used.

Try it out here

Formwork Design Guides

Slab Formwork

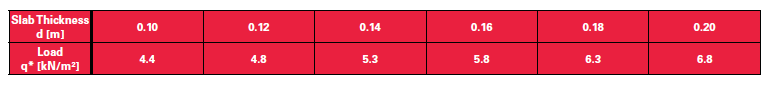

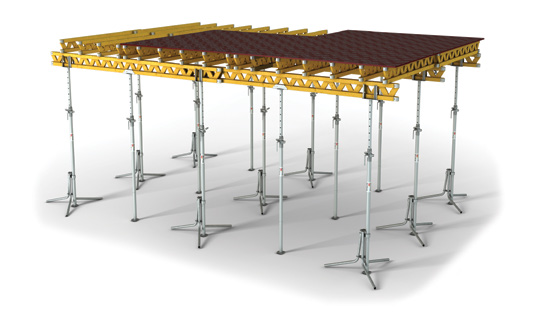

MULTIFLEX

Girder flex system using girders supported by steel props. The flex system allows for flexibility of design, making the system versatile to use for any layout.

Technical details

- Girder slab formwork consisting of main and cross beams for the form-lining of choice

- Project-specific selection of the formwork girders and their spacing

- For slab thicknesses of up to 1000mm with GT 24 Formwork Girders, for slab thicknesses up to 500mm with VT 20K

Formwork Girders

- Adapting the individual component weights in accordance with the boundary conditions

- Free choice of shoring

- No infill areas due to project-specific planning

- Tilt-resistant support of the cross beams on the main beams through the use of Flexclips

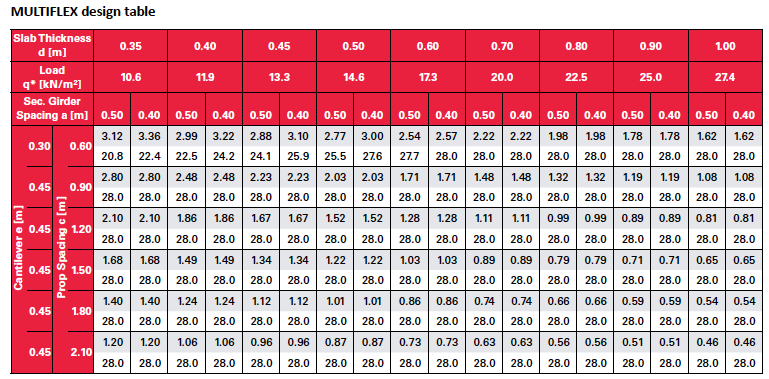

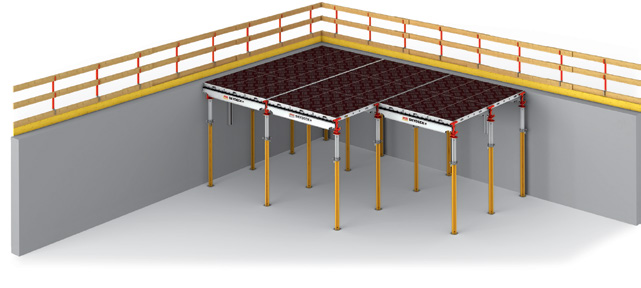

SKYDECK

Modular aluminium panel system supported by steel props. With a quick-stripping drop-head, to allow for early stripping and back-propping.

Technical details

- Panel slab formwork with lightweight aluminium system components including form-lining

- For slab thicknesses up to 420mm (with 225mm main beam) or with 1,5m main beam and 750mm panel width for slab thicknesses up to 1090mm

- With lightweight individual components (panels and main beams weigh only 15.5kg respectively)

- Systematic assembly sequence whereby the size of the panel dictates the prop position

- Only 0.29 props per m² of slab formwork

- Through the change in the direction of the panel, filler areas are reduced to a minimum

- With practical accessories for fast longitudinal and lateral compensations as well as the closing of residual gaps

- High level of safety at slab edges with cantilevered girders and SKYDECK platforms

- Safety on the front side by means of end guardrails that can be installed in any position on the main beams without requiring tools.

Wall Formwork

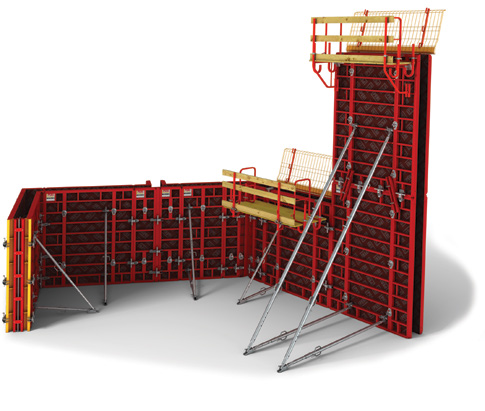

DOMINO

Standard steel frame panel system, with a plywood form-lining. The panel system reduces the number of ties and couplers required to increase formwork turnover times.

Technical details

- Light aluminium panel formwork for a wide range of uses, can also be mounted without requiring a crane

- Panel heights up 2.5m, panel widths up to 1m (standard version)

- Maximum permissible fresh concrete pressure: 60 kN/m²

- All connections are guaranteed to be flush, aligned and tight with the DRS Alignment Coupler

- DKS Wedge Connector for ensuring easy connections in the foundations with lower load-bearing requirements

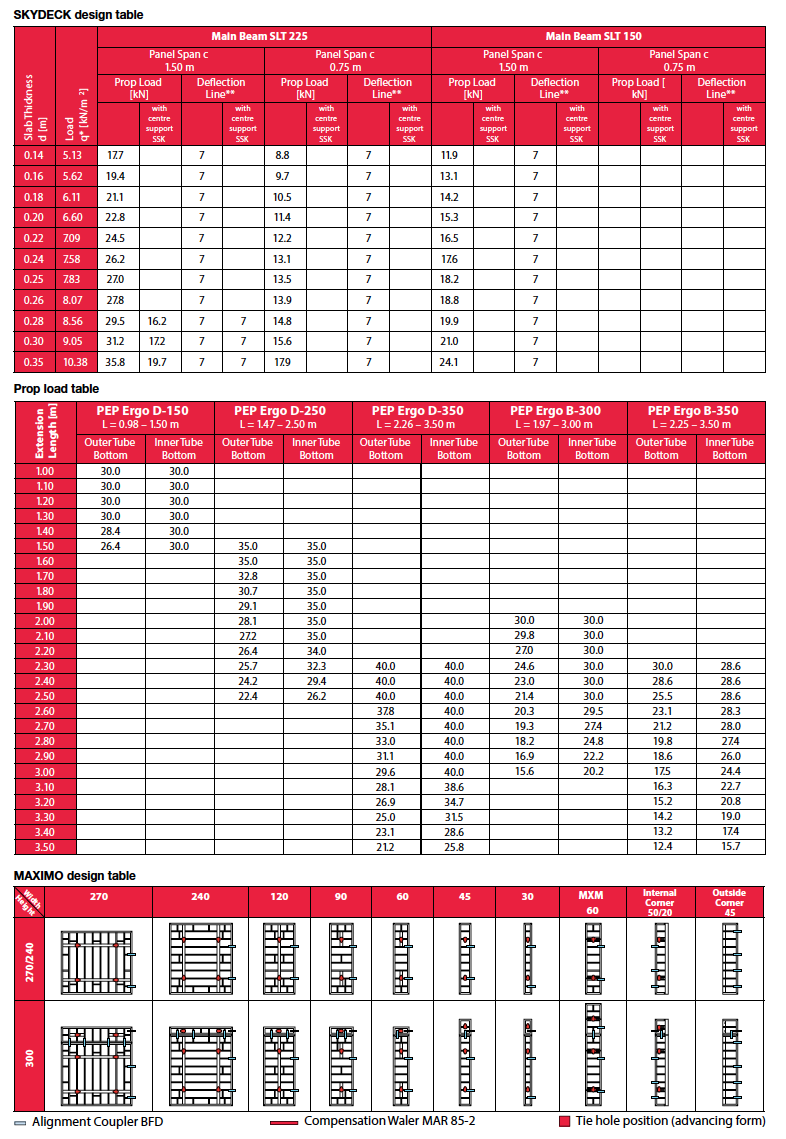

MAXIMO

Standard steel frame panel system, with a plywood form-lining. With a new tie technology, this system allows for “single-sided” tie installation so only one man is required for the job. In addition the MX tie technology prevents the need for spacer tubes and cones.

Technical details

- Flexible usable panel formwork with minimal working time values, compatible with TRIO panel formwork.

- Panel heights up to 3.3m, panel widths up to 2.4m (standard); Panel heights 3m and 3.6m (with MX 18 Tie System; not available as rentable item)

- Maximum permissible fresh concrete pressure: 80 kN/m²

- Use with MX tie technology for wall thicknesses from 150mm to 600mm (wall thickness adjustable on tie)

- Use with DW ties for thicker walls

- Easy cleaning due to the powder coating of the frame

- Flush, aligned and tight connections with the BFD Alignment Coupler – including filler timber compensations up to 10 cm

- MAXIMO requires up to 40% fewer tie points as conventional systems

- Closing of unused anchor positions is not required as each tie point is normally used.

- Improved corrosion protection through cavity protection on the profi le inner surfaces

- The reference working time values lie between 0.15 h/m² and 0.38 h/m² – this means up to 50 % less working time as required for conventional panel formwork.

Universal lightweight formwork for walls, columns and slabs

DUO

DUO can be used for foundations, walls and columns as well as for slabs and beams. The system is characterised by the extremely simple handling and the minimum number of different system components. Almost all operations with DUO can be carried out without tools while the working steps are very easy to understand. Even those less experienced users of system formwork can work quickly and efficiently with DUO. New is not only the concept but also, in particular, the material used. Both the panels- including the formwork – and the DUO accessories are made of technical polymers. Due to the low weight, no crane is required for assembly operations.

Universally applicable

Flexible forming of walls, columns and slabs using only one system

Ergonomic in all respects

Low weight, crane-free handling and intuitive application

Easy replacement of form-lining

Quick repair with just a few screws – without requiring any special skills

Technical details

- Particularly lightweight panel formwork made of innovative techno-polymers for forming walls, columns and slabs

- High degree of resistance against all environmental influences; 100% recyclable

- Elements with heights of 600mm and 1,35m as well as up to 900mm widths

- Max. permissible fresh concrete pressure: 50 kN/m² (for walls)

- Max. permissible fresh concrete pressure: 80 kN/m² (for columns and wall sections)

- For square and rectangular columns from 150mm x 150mm up to 550mm x 550mm in 50mm increments

- Optimised for slabs up to 300mm thick

- Low-noise assembly without requiring a hammer