Chapter 19

CEILINGS AND PARTITIONS

Introduction

Ceilings

Dry-walling Systems

References

Introduction

A ceiling is the non-structural surface fitted below the underside of a roof, timber framed floor or the underside of a concrete slab. Ceilings are mostly horizontal but can also follow the shape or angle of the roof. Suspended ceilings also referred as acoustic ceilings are non-structural made up of small boards (tiles) that are removable. Ceilings have no bearing on walls, being entirely supported from above by the overhead structural element(s) from which it is suspended.

Ceilings are also an important insulating building component and also support other insulation materials above it. Dry-walling also sometimes referred to as partitioning has been used in commercial and industrial buildings for a long time. Dry-walling is being used more often in the residential sector of the market. Residential Dry-walling systems have been used almost exclusively in many parts of the world.

Ceilings

Terminology

Cornices (for ceilings)

An ornamental moulding of wood, gypsum/paper (which has been the most popular for decades), polystyrene or plaster that encircles a room just below the ceiling and where it intersects with the walls.

Plasterboard/gypsum board

A paper covered gypsum core board. A popular brand for many years has been Rhinoboard.

Brander (brandering)

Timber strip usually about 38mm by 38mm in size and cut from saligna or pine; nailed to the underside of the roof elements and the ceiling nailed to the branders. Steel brandering has become more popular and more economical than conventional timber brandering.

Hanger straps/wire

Used to fix the framework of a ceiling to the structural elements above e.g. the roof.

Tees

Is a metal T shaped strip fixed to the hangers laid out in a rectangular grid. Ceiling tiles are then fitted into these rectangles and are held up by the T shaped strip.

Ceiling tile

Usually rectangular in shape and made from various different material. The tile is commonly covered with vinyl available in various shades and patterns.

Ceiling system

A ceiling system includes all the components that make up a completed and functional ceiling.

Jointing tape

Self-adhesive ceiling jointing tape used on joints which are to be plastered, acting as a reinforcing membrane for the joint.

Standards and regulations

Gyproc RhinoBoard

The Gyproc RhinoBoard range is manufactured according to SANS 266. The SABS specification incorporates ISO6308- 1980 gypsum plasterboard specification with modifications.

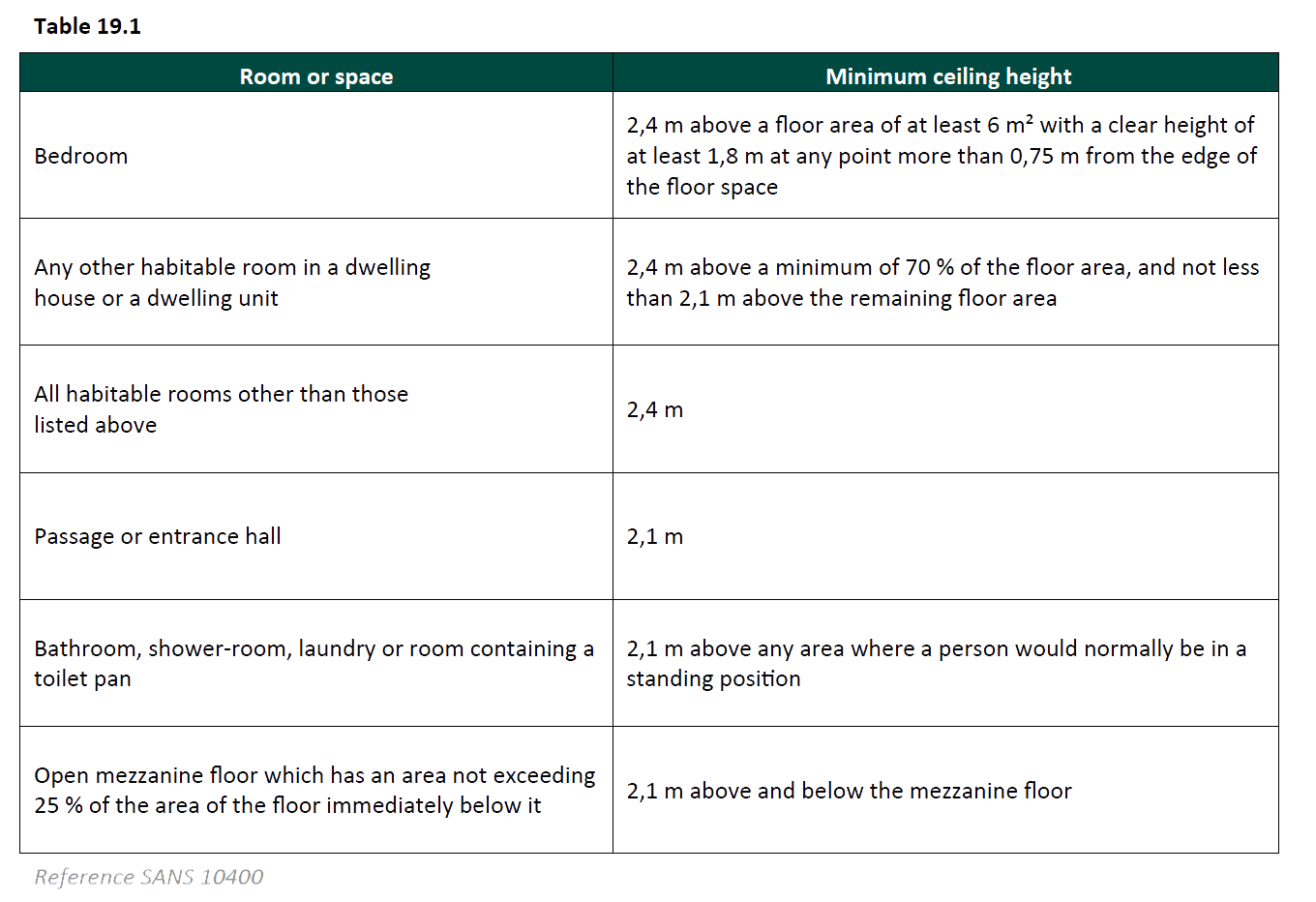

Room height

The height of any room (ceiling height) shall be not less than that prescribed Table 19.1 on the following page. Measured from the top of the finished floor to:

- the underside of the ceiling

- the underside of the roof covering where there is no ceiling

- the underside of any structural members where these structural members project below the ceiling or roof covering and the plan area of these projections exceeds 30 % of the floor plan area of the room.

Where any structural member projects below the level of the ceiling or, where there is no ceiling, below the level of the roof covering, the height of this projection shall be not less than 2,1 m measured from finished floor level.

Types of ceiling

Decorative

Decorative can having several meanings and what might be pleasing to one individual may be unappealing to another. Bamboo, grass, tented areas, formed ceilings, woven fabric are just some of the materials that can be used in decorative ceilings. Painting ceilings is one way of decoration and many churches have fabulously painted ceiling the Sistine Chapel being most famous.

Suspended ceilings

As the term suggests, these ceilings are suspended from the structures that exist above the ceiling. The ceiling and its framework are suspended from above by wire or metal straps. The lightweight

framework of powder coated galvanized steel or aluminium has main runners and cross runners. These stiffen the ceiling, which is normally of laid in tiles, removable for access. A suspended ceiling may be simply a false ceiling, but more often hides services such as air-conditioning ducts and plumbing pipes.

Suspended ceilings are seldom used in residential buildings. An extensive selection of ceiling options addressing all technical, functional and aesthetic requirements exist; with tiles typically available in mineral fibre or glass reinforced gypsum in an array of textures, dimensions and edge details. Suspended ceilings may also be constructed using conventional plaster board and then plastered.

- What module size will best suit the application e.g. 600mm x 600mm or 1200mm x 600mm. The exact or nominal panel size may differ depending on the particular system required.

- The direction and pattern indicating the way the tiles should be placed should be indicated on the ceiling plans.

- The grid is primarily intended to support the distributed load from the ceiling tiles or panels. (different systems can accommodate different loads from as little as 6 kg/m² up 14kg/ m²) if the

recommended load is exceeded, deflection of the grid, between points of support will occur. - Luminaries and air-conditioning grilles should be independently supported so as to avoid loading the ceiling system.

Plaster board ceilings are also referred to as nail-up ceilings. The board has a gypsum core wrapped in robust paper and as a composite has amazing strength. Rhinoboard has become a household name over the years and the common specifications for the fitting of Rhinoboard are listed as follows:

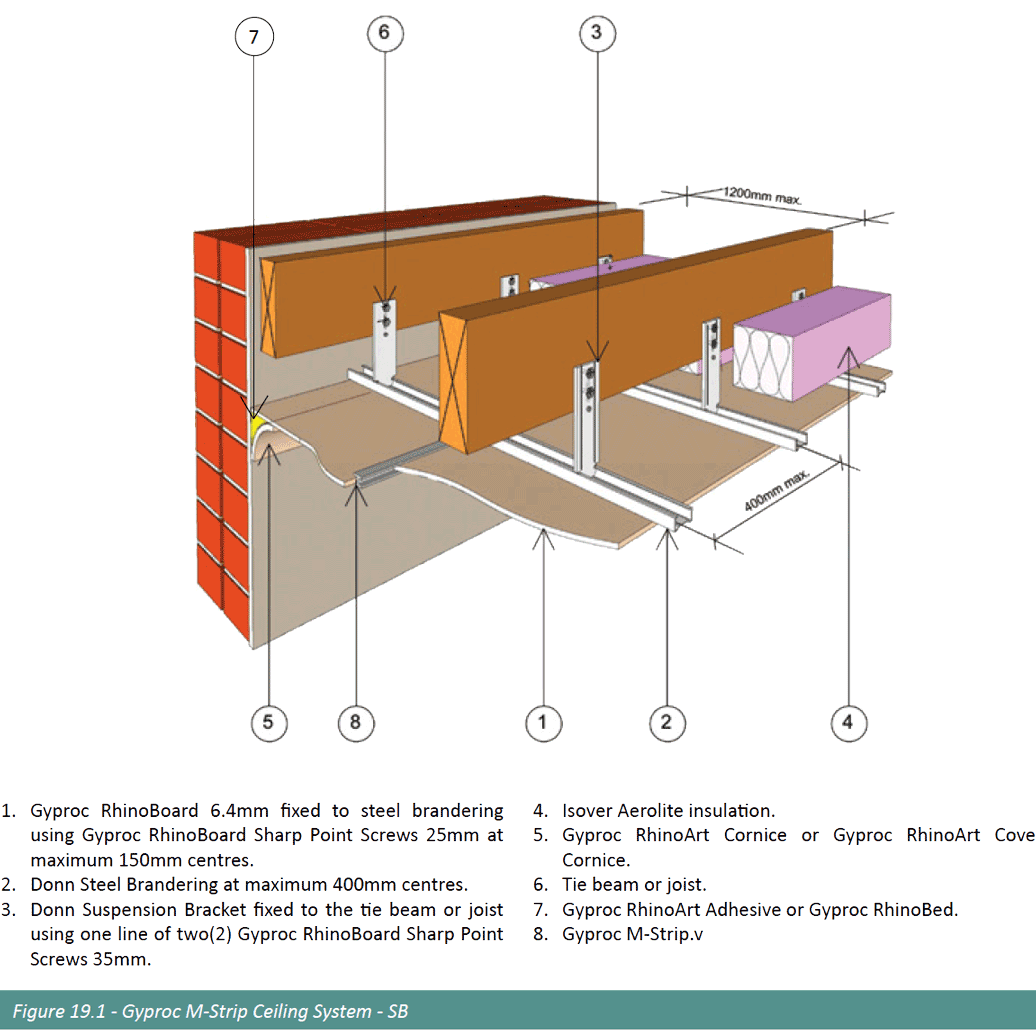

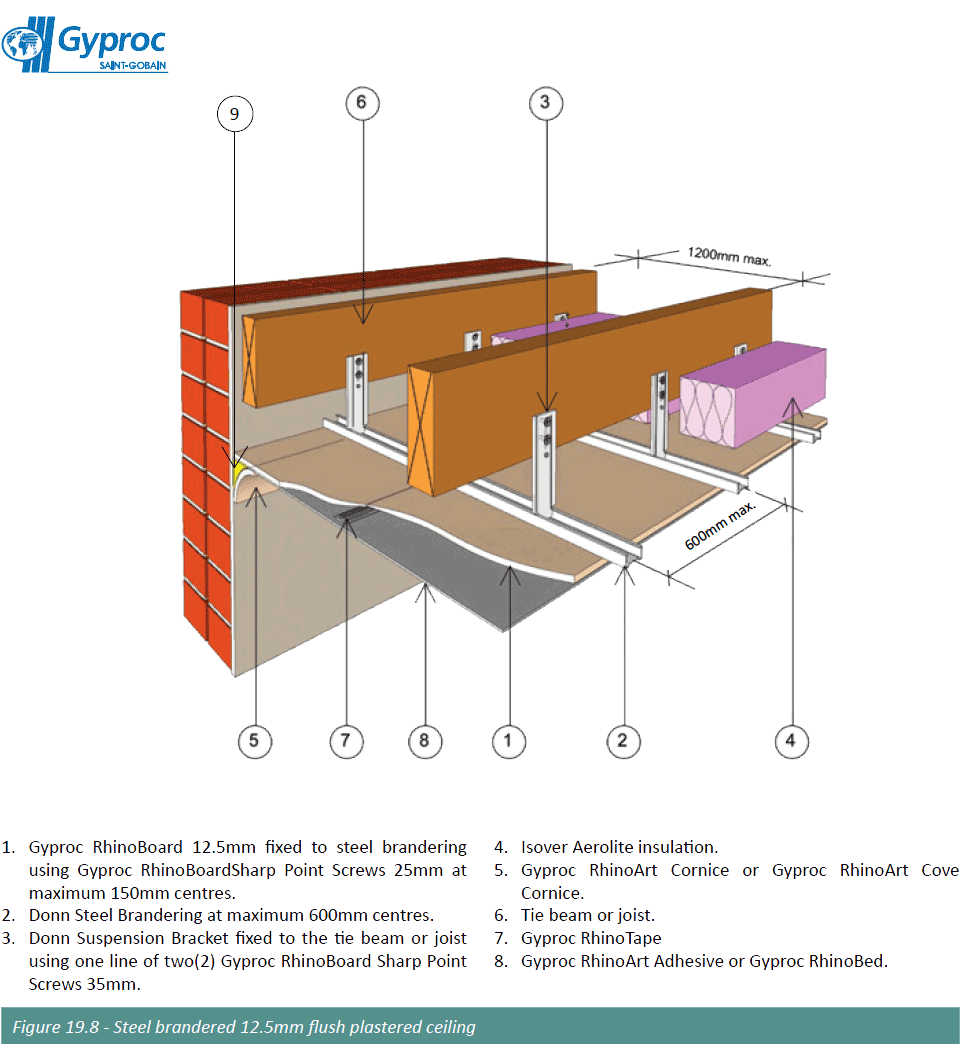

Gyproc M-Strip Ceiling System – SB

Gyproc RhinoBoard 6.4mm M-Strip ceiling consisting of steel branders fixed at 400mm centres in one direction onto which RhinoBoard is fixed, printed side up, at right angles to the branders, using Gyproc RhinoBoard Sharp Point Screws 25mm spaced at 150mm centres. Joints between boards to consist of Gyproc M-Strip fitted over board edges with the narrow flange facing down and boards fixed onto branders to within 25mm of Gyproc M-Strip. All nail or screw heads to be stopped and sanded level when dry.

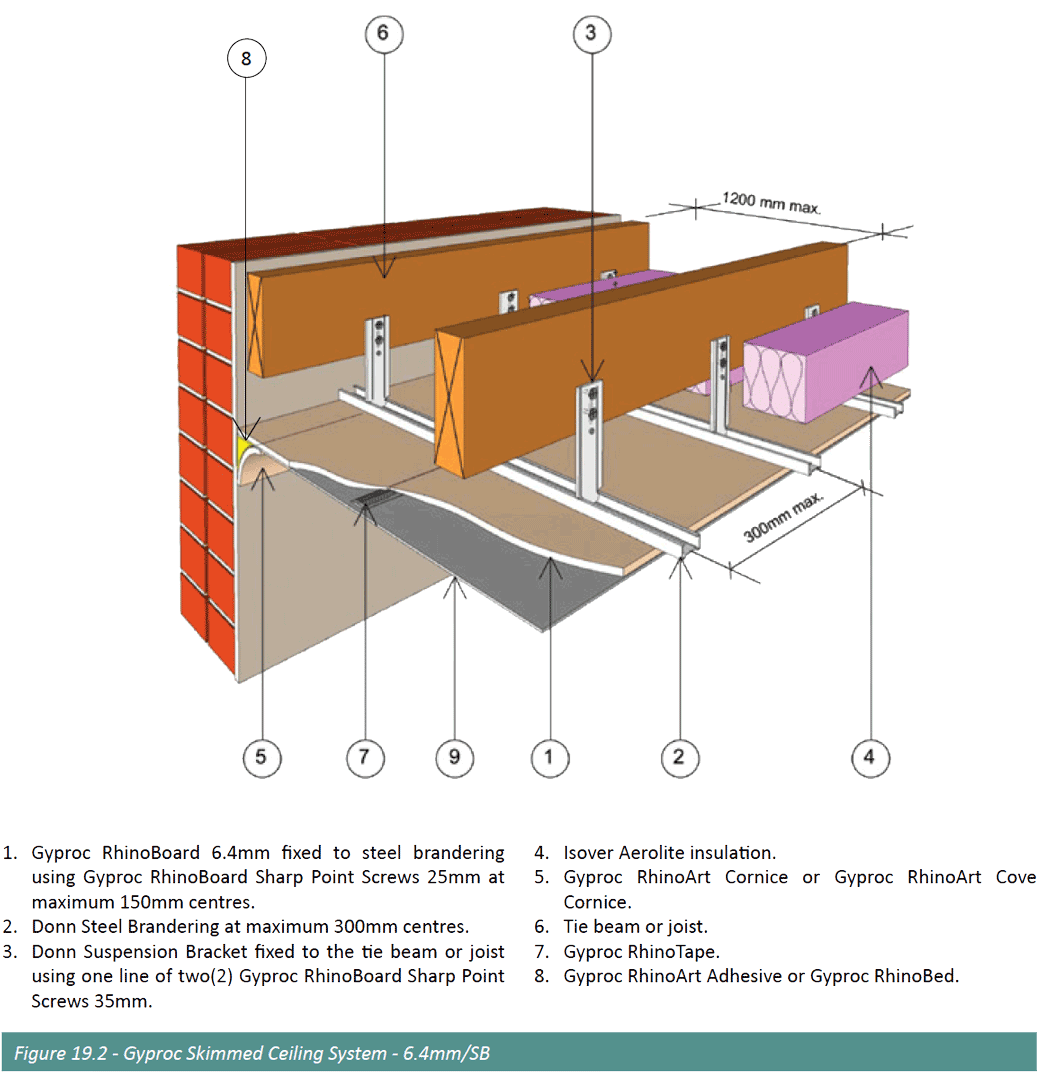

Gyproc Skimmed Ceiling System – 6.4mm Steel Brander consists of steel branders fixed at 300mm centres in one direction onto which Gyproc RhinoBoard 6.4mm is fixed at right angles to the branders with printed side up using Gyproc RhinoBoard Sharp Point Screws 25mm spaced at 150mm centres. All joints to be covered with Gyproc RhinoTape and the ceiling then plastered with a 3 – 6mm coat of Gyproc RhinoLite or Gyproc CreteStone plaster applied as per manufacturers’ instructions.

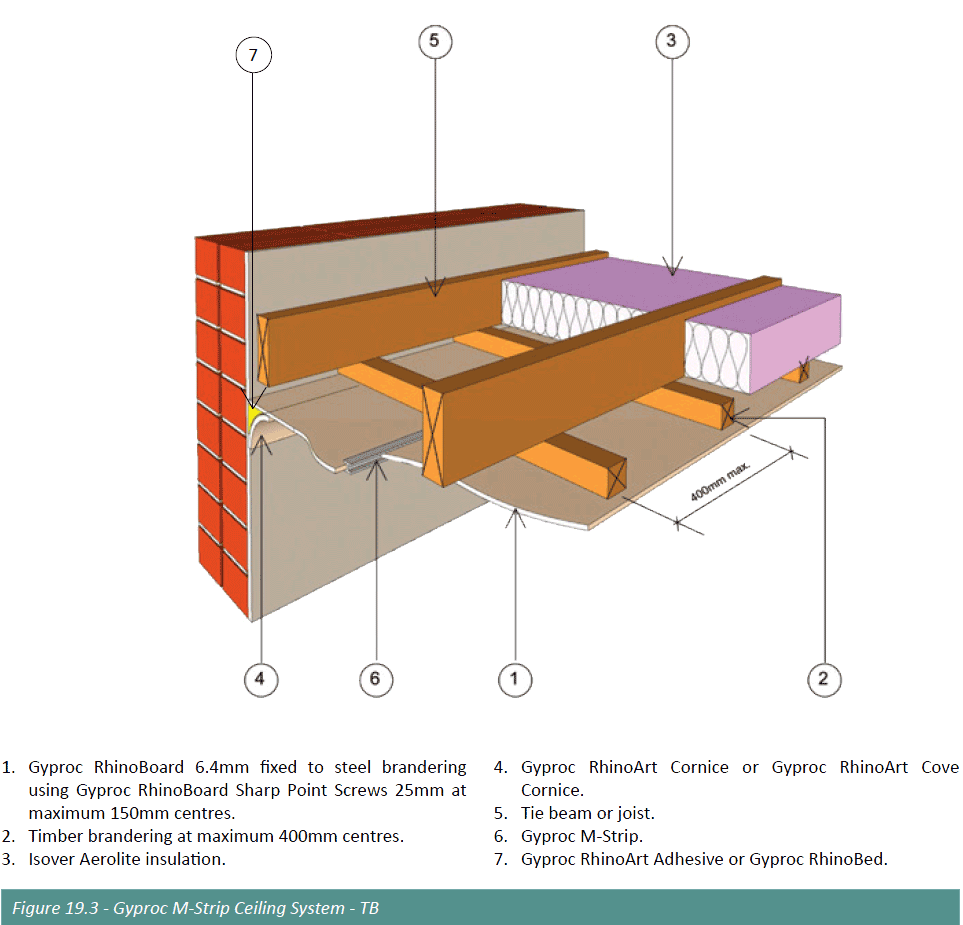

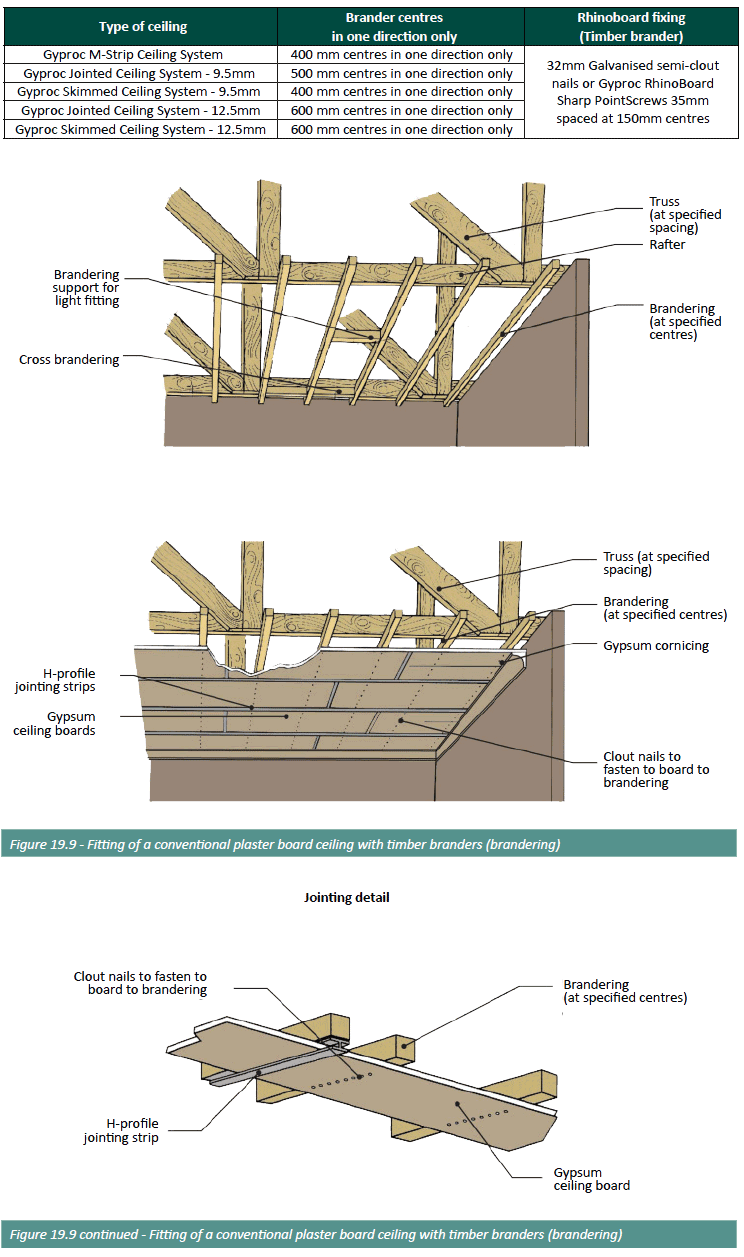

Gyproc M-Strip Ceiling System – TB consisting of SABS approved SA Pine, Saligna branders at 400mm centres in one direction onto which RhinoBoard is fixed, printed side up, at right angles to the branders, using 35mm galvanised clout nails or Gyproc RhinoBoard Sharp Point Screws 35mm spaced at 150mm centres. Joints between boards to consist of Gyproc M-Strip fitted over board edges with the narrow flange facing down and boards fixed onto branders to within 25mm of Gyproc M-Strip. All nail or screw heads to be stopped and sanded level when dry.

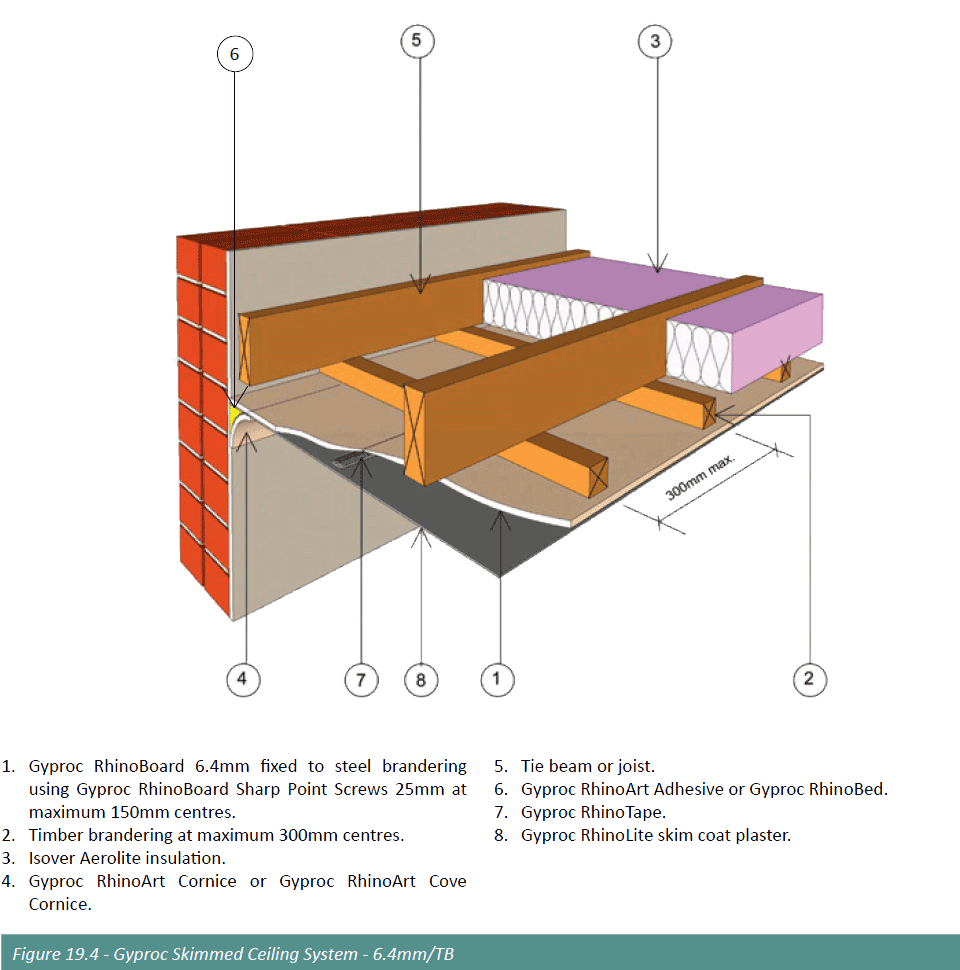

Gyproc Skimmed Ceiling System – 6.4mm/TB consists of SABS approved SA Pine, Saligna branders at 300mm centres in one direction onto which Gyproc RhinoBoard 6.4mm is fixed at right angles to the branders with printed side up using Gyproc RhinoBoard Sharp Point Screws 35mm spaced at 150mm centres. All joints to be covered with Gyproc RhinoTape and the ceiling then plastered with a 3 – 6mm coat of Gyproc RhinoLite or Gyproc CreteStone plaster applied as per manufacturers’ instructions.

N.B. Due to the extra weight from plastering it is recommended to screw the board for a more secure fix.

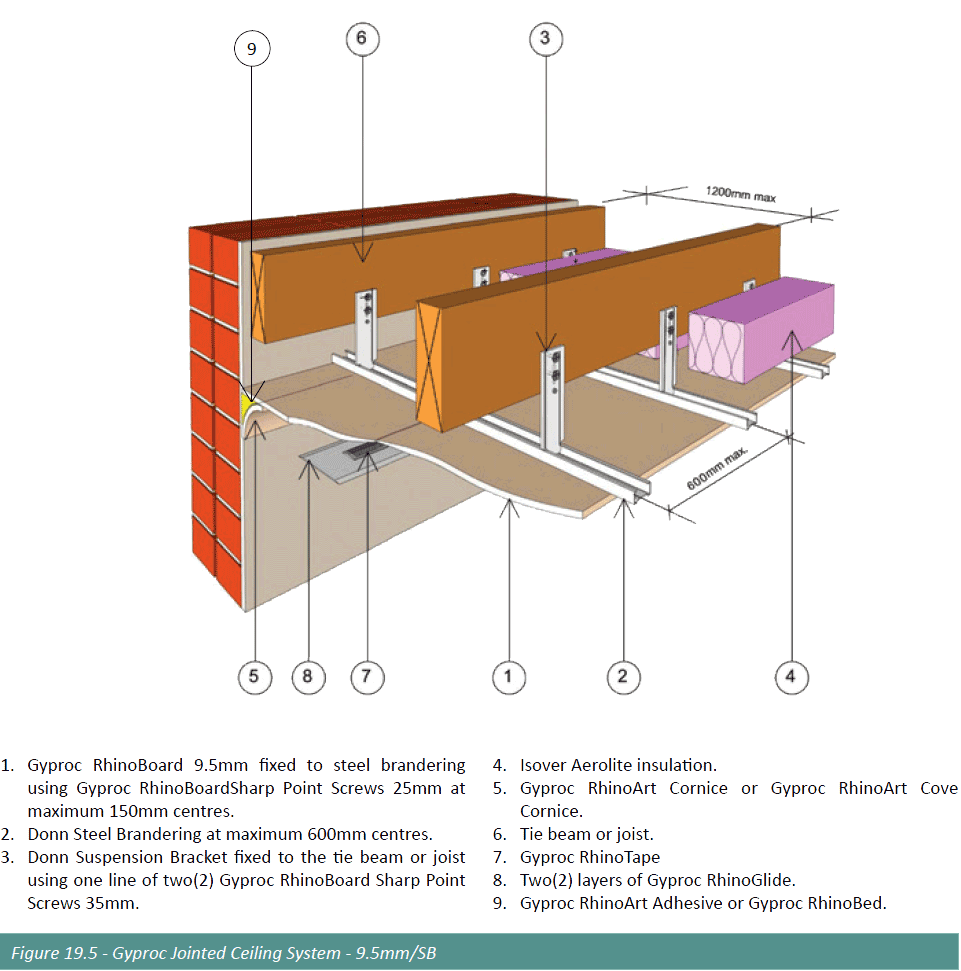

Gyproc Jointed Ceiling System – 9.5mm/SB ceiling consisting of steel branders or screw-up grid cross tees fixed at 600mm centres in one direction onto which RhinoBoard 9.5mm taper-edge is fixed at right angles to the branders with printed side up using Gyproc RhinoBoard Sharp Point Screws 25mm for steel spaced at 150mm centres. All joints to be taped and finished as per manufacturer’s instructions.

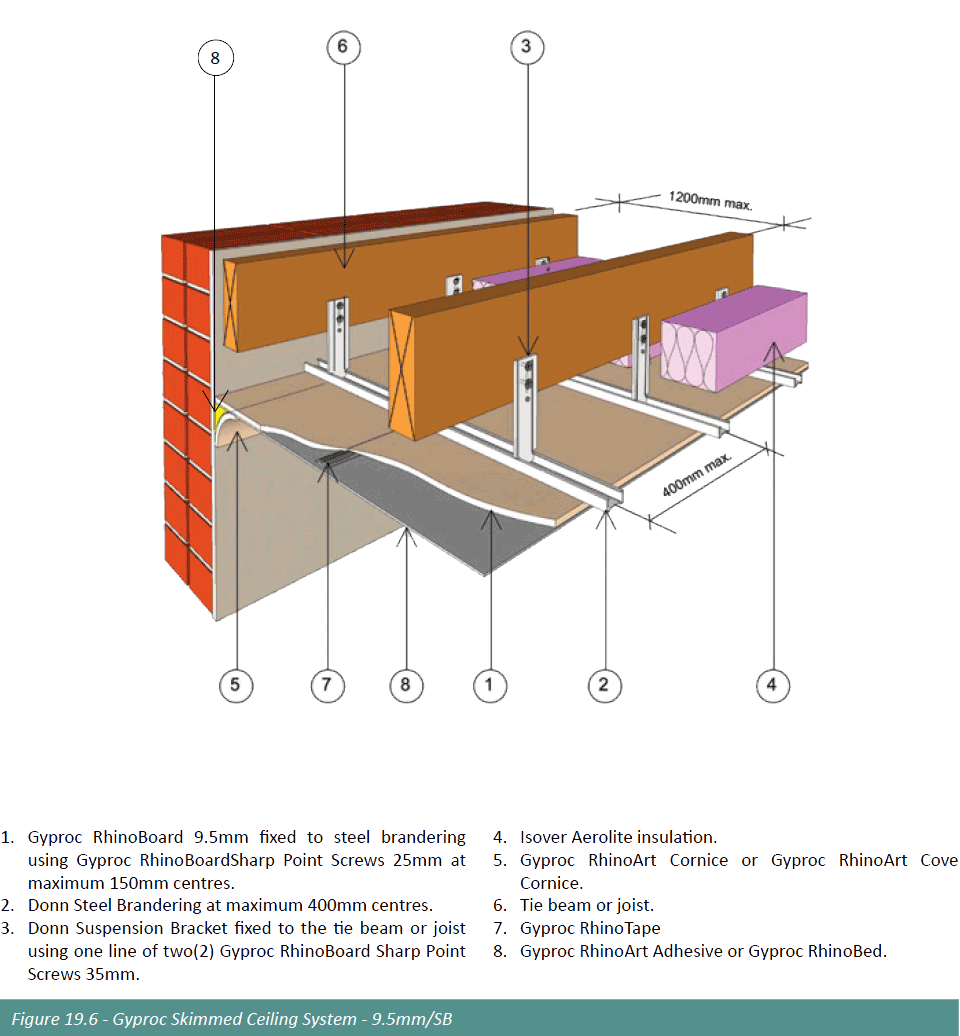

Gyproc Skimmed Ceiling System – 9.5mm/SB ceiling consists of steel brandering at 400mm centres in one direction onto which Taper or Square edge RhinoBoard 9.5mm is fixed at right angles to the branders with printed side up using Gyproc RhinoBoard Sharp Point Screws 25mm for steel spaced at 150mm centres. All joints to be covered with RhinoTape and the ceiling then plastered with a 3-6mm coat of Gyproc RhinoLite or Gyproc CreteStone plaster applied as per manufacturer’s instructions.

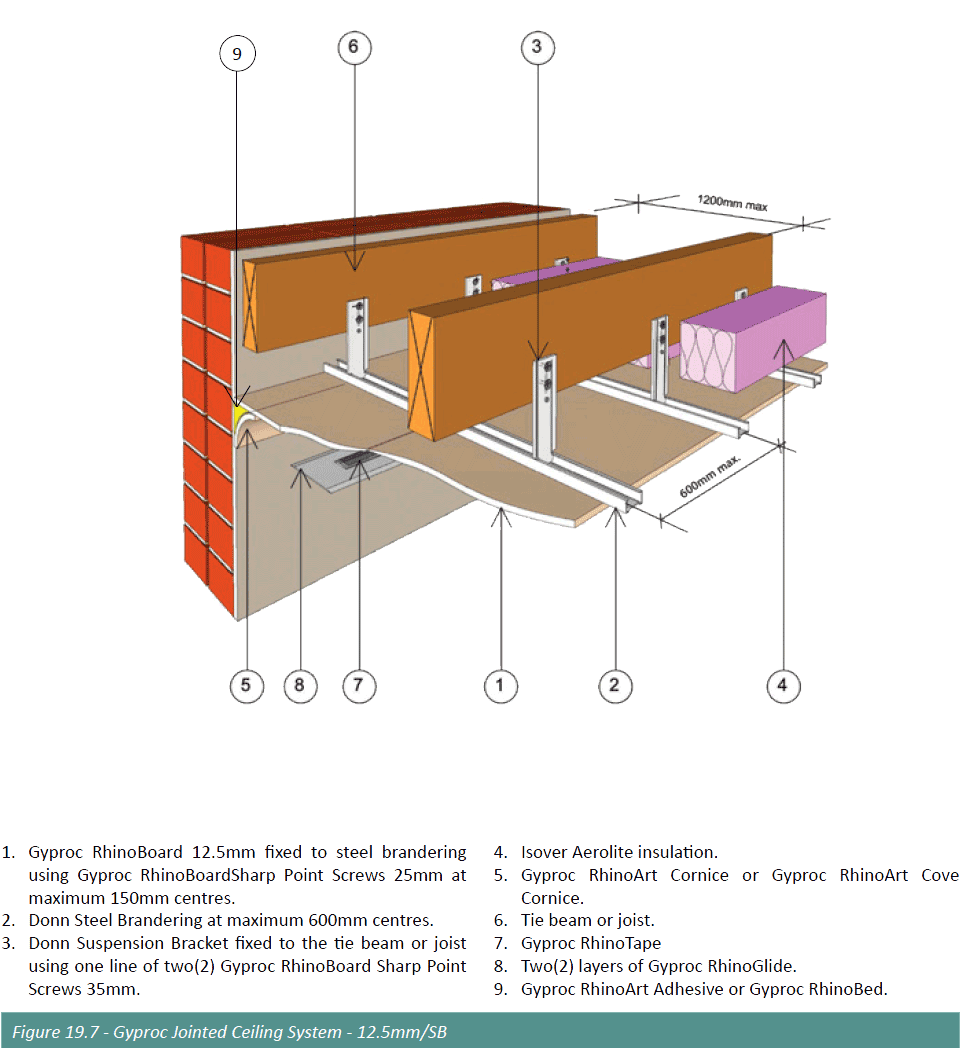

Gyproc Jointed Ceiling System – 12.5mm/SB consisting of steel brandering at 600mm centres in one direction onto which taper-edge RhinoBoard 12.5mm is fixed at right angles to the branders with printed side up using Gyproc RhinoBoard Sharp Point Screws 25mm spaced at 150mm centres. All joints to be taped and finished as per manufacturer’s drywall instructions. as per manufacturer’s instructions.

Gyproc Skimmed Ceiling System – 12.5mm/SB ceiling consists of steel brandering at 600mm centres in one direction onto which Taper RhinoBoard 12.5mm is fixed at right angles to the branders with printed side up using either Gyproc RhinoBoard Sharp Point Screws 25mm for steel spaced at 150mm centres. All joints to be covered with RhinoTape and the ceiling then plastered with a 3-6mm coat of Gyproc RhinoLite or Gyproc CreteStone plaster applied as per manufacturer’s instructions.

Brander centres

Branders (also referred to as brandering) are fixed at different centres according to the thickness of the board. A centre is the distance measured between two components measured from the centre of each component.

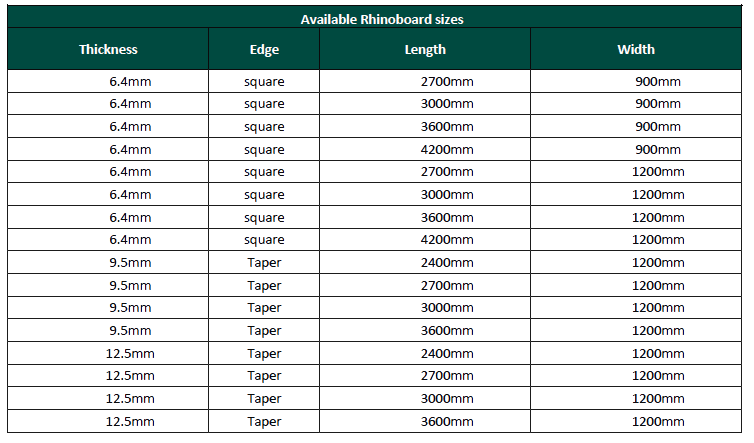

Plaster board sizes

Plaster board is available different sizes and thicknesses.

Cutting Rhinoboard

Cutting Rhinoboard is relatively easy and the following methods should be used when cutting RhinoBoard:

- Place the board flat on a level surface, with the writing facing upwards.

- Mark the cut on the face side of the board, using a chalk line or pencil.

- Score along this line with a utility knife.

- Lift the board on its side and snap it back along the cut.

- Cut the paper on the back of the board with the utility knife.

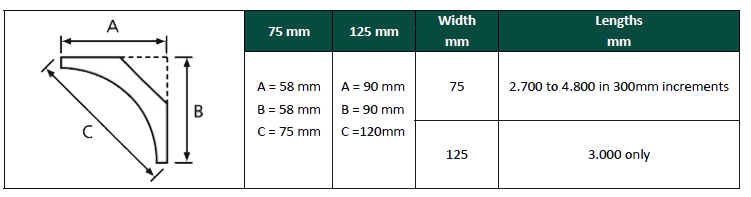

Cornices

The most commonly used cornice in the past was gypsum cornice wrapped in paper and still widely used today. It comes in two standard sizes. High density polystyrene cornices are now very popular, easy to install and economical. The cornices come in many different patterns and sizes. Below are some examples supplied by Gyproc RhinoArt.

Underside of concrete slab

Although not ideal, it is common practice to plaster the underside of a concrete slab with the finish forming a ceiling. This slab may be below another storey or a concrete roof.

Tongue & Groove Ceilings

This ceiling is constructed from timber planks with a tongue and groove joint. The tongue is clipped into the groove giving the ceiling strength and provides tidy joints which can also accommodate concealed nailing (fixing).This type of ceiling is typically found installed between exposed timber rafters where the boards can be varnished or painted to match the beams.

The commonly used type of timber is SA pine or Meranti. Other types of hardwoods and exotic timbers are used only to order. When pine is used the ceiling of often referred to as “knotty pine”.

Tongue and groove ceiling planks are usually available in the following sizes:

- Lengths – from 900mm to 6.600mm in 300mm increments.

- Widths – 63mm, 102mm, and 140mm

- Thickness – the standard thickness is 13mm with some moulding

Manufacturers producing boards in 8mm; also available in 22mm which is more commonly used for flooring. Various profiles are available such as Standard V joint, Victorian centre mould, no centre groove and square joint.

Nail-up fibre cement

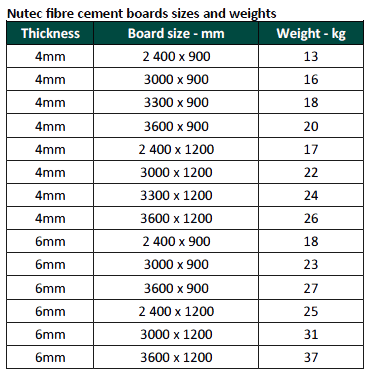

The method of installing Fibre cement ceiling board is similar to plaster board. Please refer to the text under plaster board. Everite and their product Nutec have been market leaders in fibre cement for decades. Nutec is the registered name for products manufactured without asbestos as a raw material. Nutec fibre cement products are manufactured using a mixture of cellulose fibre, cement, silica and water.

Nutec fibre cement nail-up ceiling boards exhibit exceptional performance properties, featuring high strength and dimensional stability. The inherent properties of fibre cement ensure that ceilings will not deteriorate with age, rot or be damaged by termites or rodents. In addition, they are non-combustible and form a perfect firebreak. Fibre cement boards are extensively used as nail-up ceilings and as an all-purpose building board for other interior and exterior applications. These products are not affected by moisture and are therefore ideal for use in damp areas such as kitchens, bathrooms and verandas, as well as for under eave linings. The range of fibre cement ceiling products provides a wide choice in terms of aesthetics, performance and cost. Different thicknesses are manufactured to suit specific applications i.e. 4mm internally; 6mm externally and available in different widths and lengths (see Estimating).

Ceiling insulation and SANS 10400XA

Please refer to the roofing section in this publication

Dry-Walling Systems

Terminology and definitions

Thermal insulation

Thermal conductivity (k) is the measure of a material’s ability to transmit heat, and is expressed as heat flow in watts per square metre of surface area for a temperature difference of 1°C per metre thickness and is expressed as W/m°k. Generally, denser materials have high thermal conductivity and are inefficient thermal insulants. Lightweight materials have low conductivity and are efficient thermal insulants. The lower the (k) value of the material, the better is its insulation efficiency.

RhinoBoard has a (k) value of 0.21W/m°k.

The thermal resistance (R) of a material is obtained by the following calculation where:

t = the thickness of the material in metres.

R = t/k

RhinoBoard 12.5mm R value = 0.059m2 K/W

RhinoBoard 15mm R value = 0.071m2 K/W respectively

Sound insulation

The Sound Reduction Index quoted on the individual system datasheets are those of actual tests performed by the SABS over a range of frequencies and are based on an imperforate solid RhinoBoard wall constructions. Site installation will differ from stated figures due to air leakage paths between junctions with ceiling, floor and other walls, optimum performance requires that these junctions be sealed with suitable acoustic sealants.

Fire resistance

Gypsum plasters and plasterboard provide good fire protection in buildings due to the unique behaviour of their gypsum content when exposed to fire. Pure gypsum (CaSO42H2 0) contains nearly 21% chemically bonded water in crystallised form and about 79% calcium sulphate (CaSO4) which is inert below a temperature of 1300oC. When gypsum protected elements of a structure are exposed to fire, the chemically combined water is gradually released in the form of moisture vapour. If a sufficiently high temperature is maintained, eventually all of the crystallised water will be expelled.

The process of dehydrating gypsum by exposure to heat, known as “calcination”, commences at the surface exposed to the fire and proceeds gradually through the gypsum layer (i.e. the thickness of the gypsum plaster covering or the core of the plasterboard). The covering of calcinated gypsum formed on the exposed face adheres tenaciously to the uncalcinated material and serves to retard the process, which becomes progressively slower as the thickness of calcinated gypsum increases.

While this process continues, the temperature directly behind the plane of calcination is only slightly higher than that of boiling water (100oC) and therefore, until all the crystallised water has been liberated, the temperature of materials adjacent to, or in contact with, the unexposed side cannot exceed 100oC. This temperature is well below that at which materials stored in buildings will ignite. Once the gypsum layer is completely calcinated, the residue (calcium sulphate) continues to act as an insulating barrier for as long as it remains intact.

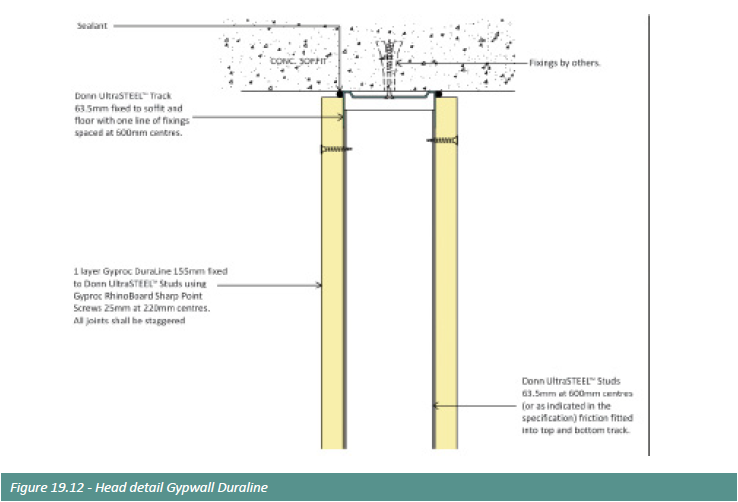

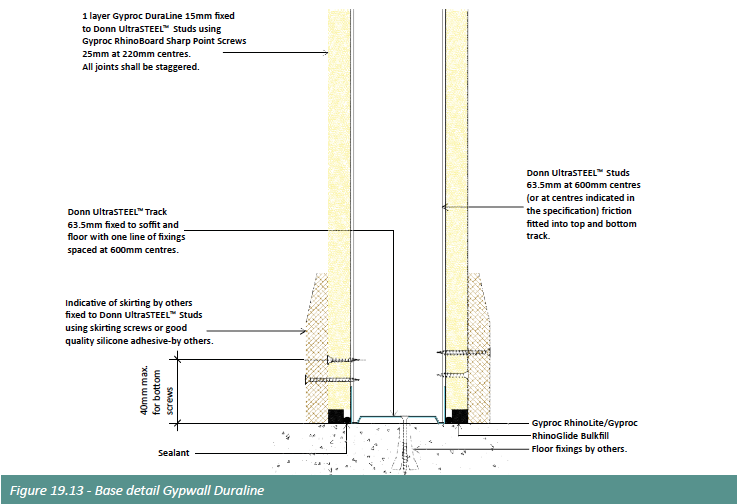

Stud

A U shaped vertical framing member used in building drywalls. Studs are manufactured in different sizes and are also made from steel.

Track

A horizontal U shaped metal component fixed to a floor or ceiling and used to anchor studs and form part of the framework in dry-walling. ?

Did you know? Gypsum is a naturally occurring mineral that is also known as selenite and alabaster. The word “gypsum” is derived from the Greek word for a calcified mineral. “Selenite” comes from the Greek word that means “moon rock,” because of the mineral’s pearly surface.

Types of board manufactured by Gyproc

Gyproc RhinoBoard

RhinoBoard is a plasterboard and consists of an aerated or foamed gypsum core encased in, and firmly bonded to, special paper liners. RhinoBoard is used as lining/cladding for ceilings, drywalls and drylining. RhinoBoard is non-combustible and it is used as a lining in fire rated drywall and ceiling systems.

The face (unprinted) surface should receive all decoration (i.e. gypsum based plaster, paint, vinyl, etc.).

It is not recommended for use in industrial kitchens and industrial bathrooms or exterior applications.

Gyproc RhinoBoard FireStop

This gypsum plasterboard has added fibreglass strands and unexfoliated vermiculite impregnated into the gypsum core to provide increased fire resistance. It is lined with pink paper.

Gyproc RhinoBoard Moisture-Resistant

This gypsum plasterboard is moisture resistant and is lined on both sides with a distinctive green paper. The core of the board is impregnated with water repellant additives and is lined with a distinctive waxy green paper. RhinoBoard MoistureResistant is suitable for use in showers, bathrooms and kitchens and where ceramic wall tiling is required. It is not suitable for protection against continuous dampness or a base for cementitious rendering. Weber preparation compounds must be used as per Weber manufacturers’ instructions.

Gyproc RhinoBoard SoundBloc

Effective sound insulation is necessity as peace and quiet are essential to relaxation healing and concentration. Long-term noise disturbance may even lead to significant health problems.

Dry-walling systems

There are many different dry-walling systems designed and constructed to meet different requirements. Gyproc are market leaders in the manufacture of components required to construct different systems. Some of Gyproc’s systems are:

Gyproc Classic Wall Systems with Activ’Air

Activ’Air® is a revolutionary plasterboard from Gyproc that uses an innovative technology to actively improve indoor air quality removing up to 70% of the formaldehydes out of the air and keeping them out. Activ’Air’s technology takes the formaldehydes and other pollutants, and converts them into safe, inert compounds that, once captured in the board, cannot be released back into the air. It keeps working for up to 50 years, based on tests and analysis, even after multiple renovations. There is a rapidly growing awareness of the importance of indoor air quality and its impact on health and productivity.

Gyproc Classic Wall Systems

Gyproc Classic Wall Systems are the industry’s original lightweight, non load bearing drywall system providing cost effective, multipurpose solutions for all types of buildings.

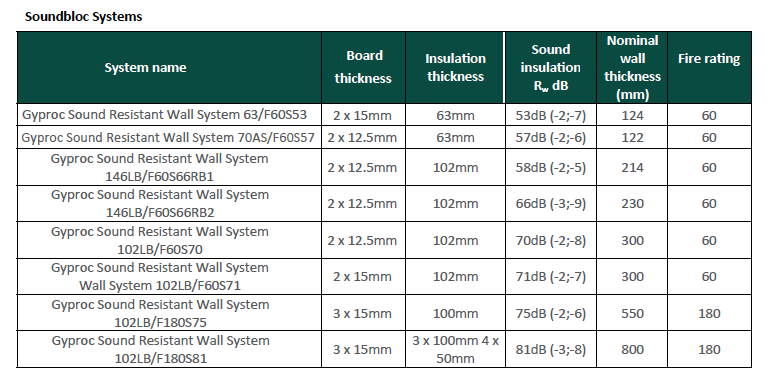

Gyproc Sound Resistant Wall Systems

Gyproc Sound Resistant Wall Systems, made of SoundBloc plasterboard (blue paper lining) have been designed and developed with sound insulating properties in mind. There are eight different SounBloc systems. See table below.

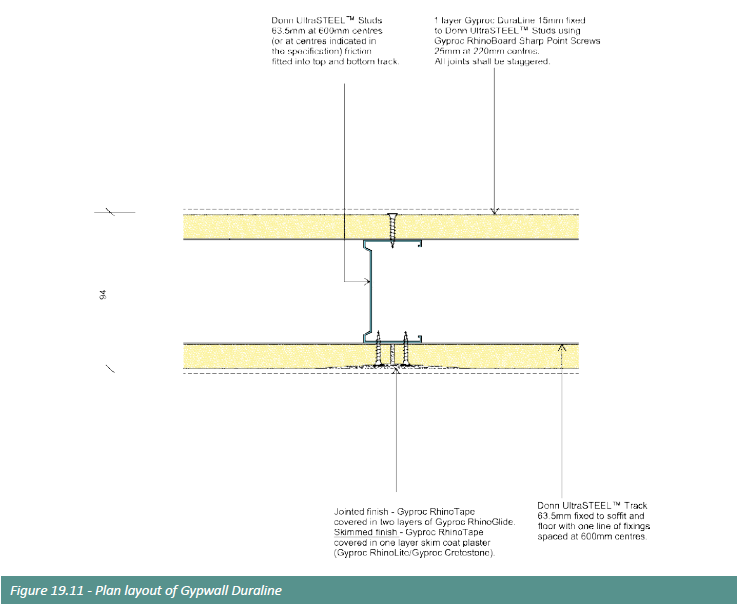

Gyproc Impact Resistant Wall Systems

Gyproc Impact Resistant Wall Systems is a high impact-resistant drywall system for use where a more durable structure is required. It provides a lightweight, cost-effective, non-loadbearing drywall suitable for all types of commercial, healthcare and educational buildings. Gyproc Impact Resistant Wall Systems made of DuraLine plasterboard (yellow paper lining) have been designed and developed with a higher density core to give greater impact resistance in heavy use areas.

Gyproc Fire Resistant Wall Systems are non load bearing high performance fire resistance systems providing a fire rating up to 120 minutes. Used in retail environments, storage areas and residential applications.

Gyproc Moisture Resistant Wall System

Gyproc Moisture Resistant Wall System are lightweight, non-load bearing walling systems where the Gyproc MoistureResistant board has water repellent additives in the core and a distinctive green waxy paper liner.

DryLining

GypWall DryLining is used in offices, internal residential walling, hotels, hospitals and schools applied on new or existing masonry work. A basic drylining system primarily for the housing market and refurbishment sector consists of a plasterboard system that replaces a wet sand cement plaster with a drylining that is smooth, level and contributes to providing a cavity for insulation to masonry walls.

Gyproc Secure Wall System

Gyproc Secure Wall System is a lightweight, non load bearing security wall system, offering high resistance to determined attack.

Did you know? The name “drywall” refers to the fact that walls made of the material are installed without the use of water.

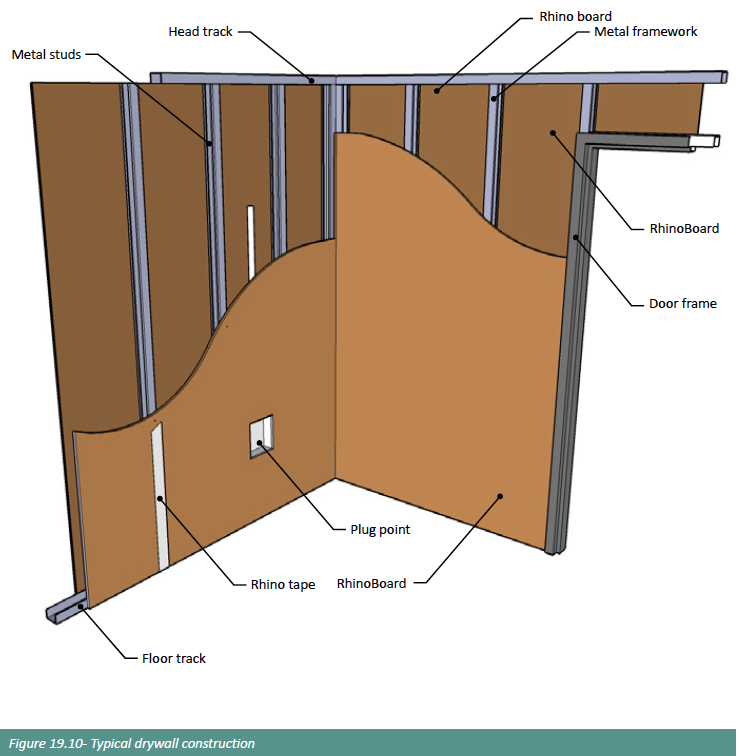

Drywall installation

In simple terms drywalling consists of a framework either in wood or steel and boards are then fixed to this frame. Modern systems as indicated above offer various solutions for different requirements.

Benefits of dry-walling systems

- Accommodates services such as electrical and plumbing within the drywall cavity

- Lightweight alternative to traditional construction

- Fire resistance up to 180 minutes

- Steel framework will not twist or warp

- Ability to achieve a smooth finish

- Can be painted, wallpapered and tiled

- Corners and edges are straight and sharp

- Less material wastage, cleaner site conditions

- Environmentally friendly products

- Versatile with the ability to create arches and recesses easily

Drywall finishes

Jointed Finishing:

Apply Gyproc RhinoTape to all joints and internal corners. Cover the Gyproc RhinoTape with two layers of Gyproc RhinoGlide. Fit a Donn Corner bead embedded in Gyproc RhinoGlide plaster to all external corners. Paint according to paint manufacturer’s specification.

Skimmed Finishing:

Apply Gyproc RhinoTape to all joints and internal corners. Cover the Gyproc RhinoTape with one layer of Gyproc.

Skim the surface using one layer of Gyproc RhinoLite/Gyproc CreteStone. Fit a Donn Corner bead embedded in Gyproc RhinoLite/ Gyproc CreteStone plaster to all external corners. Paint according to paint manufacturer’s specification.

Wall paper

Apply Gyproc RhinoTape to all joints and internal corners. Cover the Gyproc RhinoTape with two layers of Gyproc RhinoGlide.

Fit a Donn Corner bead embedded in Gyproc RhinoGlide plaster to all external corners. Fix wallpaper according to manufacturer’s specification.

Aluminium sections

Aluminium sections are manufactured in various shapes according to requirement. The basic dry-walling structure consists of a steel framework covered with board that has been screwed to this framework. The aluminium sections either finish off ends of walls or are used where walls intersect or at the bottom and top of walls. Aluminium sections are also used as frames at the juncture with glazed panels and doors.

RhinoBoard GlasRoc H

APPLICATION & INSTALLATION

GlasRoc H provides outstanding performance as a tile backing and wet areas board in environments where there is frequent exposure to moisture, such as shower enclosures, bathrooms, swimming pool areas that have controlled environments with ventilation and other applications where there is likely to be moisture or high humidity present.

General

It is important to observe appropriate health and safety legislation when working on site i.e. personal protective clothing and equipment, etc. The following notes are intended as general guidance only. In practice, consideration must be given to design criteria requiring specific project solutions. Gyproc GlasRoc H 12.5mm should be stored on a firm, flat and level surface in a dry place, preferably inside a building and properly protected from damp and inclement weather. If boards are to be stacked on a concrete floor inside a building, a damp proof membrane should first be laid down, or a timber platform should be provided.

Cutting

This product may be cut using a Stanley knife or blade runner and snapping the board over a straight edge. Holes for switch or socket boxes should be cut out before the boards are fixed using a Stanley knife. When cutting boards, tools should be used with care and in accordance with the manufacturers’ recommendations. Power tools should only be used by people who have been instructed and trained to use them safely. Appropriate personal protective equipment should be used.

Fixing

Lightly butt boards together. Never force boards into position. Install fixings not closer than 13mm from cut edges and 10mm from bound edges. Position cut edges to internal angles whenever possible, removing paper burrs with fine sandpaper. Stagger horizontal and vertical board joints between layers by a minimum of 600mm. Locate boards to the centre line of framing where this supports board edges or ends. There is a wide variety of fixing devices suitable for securing fixtures and fittings to lining systems. Generally, the choice of individual fixing devices will depend on the type of system and the loading requirements.

STANDARDS

This plasterboard is manufactured in accordance to EN standard EN 15283-1 Gypsum boards with fibrous reinforcement.

FIRE RESISTANCE

Please refer to the appropriate Gyproc technical literature product or systems section for information on the fire resistance of building elements lined with GlasRoc H.

LIMITATIONS

Gyproc GlasRoc H 12.5mm is unsuitable for use in temperatures above 49°C but can be subjected to freezing conditions without risk of damage. Gyproc GlasRoc H is unsuitable for any areas subjected to prolonged immersion, such as shower bases or swimming pools without ventilation and a controlled environment.

| Board Details | |

| Description | Gyproc GlasRoc H 12.5mm |

| Dimensions | 12.5 x 1200 x 2700 mm/td> |

| Weight | 10.5kg/m2 |

| Edge Type | Taper Edge |

| Fire Rating | 30 min |

| Sound Rating | Rw39 dB, Rw42 dB, Rw46 dB |

| Thermal Cond. | 0.30 W/mK |

| Pre-primed | Yes, both sides for tiling |

| Tile Loading | 32kg/m2 |

| Environment Humidity | > 90% + Condensation |

BOARD COMPOSITION

Front & Back Lining: hydrophobic treated glass material liners that are pre‑primed for tiling or decoration. Gypsum Core: ERG Technology – glass reinforced gypsum core with enhanced moisture and mould resistance properties.

BENEFITS

Easy to Install

- Up to 30% lighter weight than most cement boards.

- Twice as fast to install compared to cement boards.

- Easy to score and snap, no power tools needed.

- Fixes easily: no pre-drilling required.

- Lighter and faster construction than using masonry walls.

Environmental Benefits

- Can be recycled, unlike cement boards or masonry.

- Inorganic surface with a high resistance to mould growth.

Features & Benefits

- Vapour permeable to allow the structure to breath.

- For the purpose of National Building regulations Part T: Fire, GlasRoc H is regarding as non-combustible, i.e. Gypsum board with less than 7.5% paper or other combustibles.

- Used in building elements requiring fire resistance.

- Pre-primed for tiling.

- High resistance to mould.

- Tile loading up to 32kg/m2 at standard 600 UltraSTEEL Stud centres.

- Environmental Product Declaration (EPD) verified.

- Used in building elements where acoustic performance is required.

HANDLING

Manual off-loading of this product should be carried out with care to avoid unnecessary strain. For further information please refer to the Gyproc RhinoBoard handling section of the RhinoBoard for walls book, available to download from www.gyproc.co.za

References

Alexander G D & Van As F. 2008: Civil Technology. Johannesburg: EWA Publishing

South African Bureau of Standards. 2011/12 – SANS 10400 Part XA. Pretoria. SABS Standards Division.

Gyproc – www.gyproc.co.za