Chapter 23

GLAZING

Introduction

Terminology

Understanding Glass

Standards

Performance of Glazing

Types of Glass

Double Glazing

Types of Plastic

Introduction

This section deals with the performance of all kinds of glazing in all building types, mainly in the more traditional form of windows, and doors – from Glass terminology to standards and understanding the properties of one of the world’s most used and diversified product – Glass. Its performance is affected by numerous other factors like the framing, wall and structure, and whether the building has been appropriately designed for its particular climate and location, for example orientation. Amongst all building materials, glass has the unique property of transmitting light.

It is by means of light that we perceive the space in and around buildings. But today, window glass must perform many other functions additional to its fundamental daylighting role. Glass is also used in many other applications like glass doors, skylights, balustrades, shop fronts, glass tiles, glass bricks etc. which can also include horizontal surfaces. Furthermore we expand upon the properties and energy efficiency performance of glazing and also examine the different types of glass available in terms of the revised building regulations and more particularly SANS 10400 part XA.

Terminology

Annealed

Softening a metal or glass by heating and slow cooling

Annealed glass

See “Float glass”. During the float glass manufacturing process, the hot glass is gently cooled in the “annealing lehr”, which releases any internal stresses from the glass to enable the cutting and further processing of the glass post manufacture.

Arrissed

A basic form of edgeworking, by removing the sharp edges of cut panes of glass.

Balustrade

A barrier or form of guarding, generally waist-height, which protects people from falling where there is a change in floor level, for example stairs and balconies.

Bead

A strip of wood, metal or other suitable material attached to the glazing surround to retain the glass.

Bevelled

A decorative form of edgeworking, where the edges of a glass pane are ground and polished smoothly at an angle.

Body-tinted glass

Transparent float glass with a consistent colour throughout its depth

Borosilicate glass

Heat and chemical resistant clear glass made from borax as well as the usual silica, giving complex compounds of sodium borosilicate.

Building Regulations

Building Control legislation laid down by Acts of Parliament.

Coated glass

Thin layers of material are applied to the surface of the glass to add properties to the glass including reduced light transmission, increased solar energy elimination, colour and aesthetic properties e.g. mirrors and spectrally selective glass.

Cold zones

Areas in close proximity to glazing, especially single-glazing, where exchange of heat by radiation can lead to the sensation of feeling cold or draughts.

Colour rendering

Term given to the change in appearance of the natural colour of a material/object due to the colouration effect of light being transmitted through or reflected by the glass onto any given surface.

Condensation

Process whereby gas or vapour turns into liquid by cooling.

Cullet

Recycled glass used in the manufacture of clear float glass.

Curtain walling

Non-load bearing, typically aluminium, facade cladding system, forming an integral part of a building’s envelope

Desiccant

Generally a pure molecular sieve- or silica gel-based product, the desiccant is placed within the cavity spacer bar of doubleglazed units in order to dehydrate or to remove any residual moisture in the unit.

Double Glazed Units (DGU)

Two or more pieces of glass separated by a spacer, the airspace between the glass is critical to the insulation value of the unit. The units are designed for thermal insulation, but have the welcome advantage of reduced noise transmission and lower total solar energy transmission; and are now increasingly referred to as Sealed Insulating Glazing Units (SIGU’s) or Sealed Glazing Units (SGU’s).

Dry glazed systems

A term applied to glazing systems that use gaskets to retain the infill material (glass).

Edge clearance

The distance between the edge of the glass and rebate.

Emissivity

Emissivity is a surface characteristic of a material. It is the relative ability of a surface to absorb and emit energy in the form of radiation. Low-emissivity (Low-E) coatings reduce the normally relatively high surface emissivity of the glass. The coatings are mainly transparent over the visible wavelengths but reflect long wave infra-red radiation towards the interior of the building. The result is greatly reduced heat loss.

Energy Absorptance (A)

The percentage of solar radiant heat energy absorbed and re-emitted externally and internally by the glass.

Energy balance

The difference between the amount of heat gain and heat loss through glazing. Also known as the “Effective U-value”.

Energy Transmittance (T)

The proportion of solar radiant heat energy which is transmitted directly through glass (formerly abbreviated to DT (Direct Tranmittance)).

Façade

The front or face of a building.

Fenestration

The architectural arrangement of windows or any opening that admits daylight through the outer walls of a building.

Float glass

The foremost method of manufacturing normal glass is by the float glass method. Molten glass is poured onto molten tin, on which it floats. The glass cools to a solid as it passes over the tin and is then lifted off the tin onto rollers. It can be from 3mm to 25mm thick and is used to make laminated glass and toughened glass. Float glass has replaced plate glass and sheet glass.

G-Value

Abbreviation or symbol for “Solar factor” according to BS EN 410 (formerly abbreviated to SF (Solar Factor) or TT (Total Transmission)).

Gaskets

Pre-formed glazing materials used for bedding or securing glass and to separate the glass from the frame or fixings.

Glazing bead

See ‘Bead’.

Glazing/Glass size

The dimensions of the cut glass ready for installation, clearances having been allowed. As a general rule the industry gives width first and height second (w x h).

Head

Top member of a frame, usually horizontal.

Interlayer

The layer between two pieces of glass, which is used to make laminated glass. Usually polyvinyl butyral (PVB) is used for this purpose. The interlayer imparts additional properties to the glass including safety, security, solar control, light control, UV control, colour and sound absorption.

Laminated glass

Two or more pieces of annealed glass joined together by one or more interlayers (normally PVB). The lamination process combines the properties of the glass with the properties of the interlayer. Laminated glass that is correctly marked is a safety glass. However, unmarked glass does not qualify as safety glass. See SABS and safety marking.

Lehr

The annealing chamber on a float glass manufacturing line where the molten glass is subject to controlled cooling to obtain annealed glass, free from internal stresses, which can then be cut or worked.

Light Transmittance (T)

The proportion of the visible spectrum that is transmitted through the glass

Low E

A coating added to the surface of a glass, which increases the thermal insulation of the glass. See Emissivity.

Mullion

A vertical framing section between glass panes.

On-line coating

See “Pyrolytic coating”.

Opaque

Glass which has been fully enamelled or painted on one side to make it non-transparent.

Patterned glass

Translucent patterned glass, manufactured by rolling heatsoftened glass between embossed cylinders

Plate Glass

The plate glass process was used to produce higher quality glass, by grinding and polishing of both sides, but has now been completely superseded by the float process. Because of the long usage of the term, much currently made float glass is sometimes still incorrectly referred to as plate glass in many specifications.

PVB (Polyvinyl Butyral)

The plastic interlayer incorporated into laminated glass in order to ensure good adhesion and the mechanical and safety breakage characteristics of the glass.

Pyrolytic coating/coated

A specialist metallic coating is applied to the glass “on-line” during the float glass manufacturing process. The high temperatures involved result in the metallic oxides fusing into the surface of the glass through pyrolysis and effectively forming part of the glass.

Reflective coating/coated

A metallic coating is applied to one side of the glass in order to significantly increase the amount of reflection by the glass of both the visible and infra-red (light and heat) range of the electromagnetic spectrum.

SABS and safety marking

Any glass product that is used in construction and buildings, which is sold in South Africa, must bear the safety glass label. This label can be stamped onto the product.

Safety glass

Glass which either must not break or must break safely.

Screen-printing/screen-printed

Enamelling the surface of a sheet of glass, either partially or completely, by means of a silk-screen and thermal toughening

Shading Coefficient

The ratio of total solar energy transmission of a glass compared to the total solar energy transmission of ordinary 3 mm glass (calculated to ASHRAE summer conditions). The higher the shading coefficient, the more solar heat is allowed into the building. This measurement is dependent on environmental factors such as wind, as well as the temperature inside and outside.

Silvering or silvered

A process used in the manufacture of mirrors, whereby a silver coating is applied to one surface of the glass

Solar Energy

All energy received from the sun on the surface of the earth. This includes the energy from the ultraviolet, visible and infrared segments of the solar spectrum. For reasons of standardisation, solar energy is measured between the wavelengths 280 nm to 2500 nm (nanometres).

Solar Energy Absorption

Solar absorption is that portion of total solar energy neither transmitted nor reflected. Since solar transmittance and solar reflectance are measured directly, the following equation should be used in calculating solar absorption: Solar absorption = 1.00 – (solar transmittance) – (solar reflectance). The higher the absorption the higher the thermal stress and the more likely a glass is to crack if incorrectly glazed.

Solar Energy Reflection

The part of the sun’s energy which is reflected by the glass or glazing system. This is independent of environmental conditions.

Solar Energy Total Elimination

The part of the sun’s energy stopped by the glass or glazing system. This value will change when subjected to varying environmental conditions. In warm climates, glazing systems are compared using the ASHRAE summer daytime conditions. The environmental conditions, which affect solar heat elimination, include air speed against both surfaces of the glass, and temperature (also on both surfaces of the glass).

Solar factor g

The percentage of total solar radiant heat energy transmitted through glazing (the sum of energy transmitted directly and energy absorbed and re-emitted to the interior).

Solar heat gain

Solar radiant heat, transmitted or reemitted by glazing into a building, contributing to the build-up of heat.

Spectrally Selective Glass

Glass which is designed to allow as much visible light through as possible but as little solar heat as possible. As solar energy is also carried in the visible light part of the solar spectrum, higher solar energy elimination than 50% can only be achieved by sacrificing significant quantities of light.

Sputtered coating/coated

An advanced metallic coating is applied to the glass “offline” or after the float glass manufacturing process, by a technique called magnetically enhanced cathodic sputtering under vacuum conditions.

SSS

Reference for standard stock sizes of glass.

Strength

Referring to laminated glass, the strength is defined by the performance of the polyvinyl butyral (PVB) interlayer. NS is Normal Strength and usually relates to a 0.38 mm polyvinyl butyral (PVB) interlayer. HPR is High Penetration Resistance and usually relates to a polyvinyl butyral (PVB) thickness of 0.76 mm. HI is High Impact and usually relates to a polyvinyl butyral (PVB) interlayer of 1.52 mm. NS and HPR comply with the requirements of SABS 1263-1, whilst HI also complies with SABS 1263-2.

Structural glazing

Glass acting as a structural support to other parts of the building structure, for example glass fins. It can also refer to glass that is fixed by means of bolted connectors where the glass is not acting as a structural element.

Thickness

The thickness of ordinary float and rolled glass is normally described as the nearest whole number, within the thickness variation. For example, 3 mm glass has a tolerance of plus/ minus 0.2 mm. Laminated glass is more complicated due to the thickness of the interlayer. The internationally accepted method of describing laminated glass is as follows: The laminate is made from two or more pieces of glass. Each glass has a nominal thickness, such as 3, 4, 5 or 6 millimetres. The glass is laminated using a layer or layers of a plastic material, polyvinyl butyral (PVB). A standard PVB has a thickness of 0.38 mm. Also available are 0.76 mm, 1.14 mm, and 1.52 mm. The thickness of a laminate made of two 3 mm glasses and a 0.38 mm vinyl is therefore 6.38 mm. Two 3 mm glasses and 0.76 mm vinyl is therefore 6.76 mm.

Tinted Glass

Glass which has had a colour either incorporated into the glass itself or introduced into the interlayer of a laminated glass.

Tinted interlayer

A coloured pvb interlayer between two or more panes of glass.

Total Solar Energy Transmittance

The ratio of the amount of total solar energy in the full solar wavelength range 280 nm to 2500 nm, that is allowed to pass through a glazing system to the amount of total solar energy falling on that glazing system.

Toughened Glass

Annealed glass which has had its surfaces placed into compression in a process similar to tempering steel. The glass is much stronger in tension — at least five times stronger than ordinary annealed glass. Toughened glass is manufactured predominantly by heating up the glass and cooling it rapidly in air. Once thermally toughened, the glass will shatter if cut or drilled, therefore any holes or shaping are done before toughening.

Translucent

Transmitting light but obscuring clear vision.

Transom

A horizontal framing bar between glass panes. It can also be used to refer to a fanlight over a door.

U-Value

This is a measure of the rate of heat loss of a building component. It is expressed as Watts per square metre, per degree Kelvin, W/m2K. The lower the U-Factor, the better the insulation qualities of the glazing system and the more effective the control of heat loss or gain. The U-value is dependent on environmental conditions.

Ultra-Violet (UV) Transmittance

The ratio of the amount of total UV solar energy 300nm to 380 nm that is allowed to pass through a glazing system compared to the amount of total UV solar energy falling on the glazing system. Ultra-violet is one portion of the total solar energy spectrum, which greatly contributes to fading, and deterioration of fabric and furnishings.

Visible Light Transmittance (VT)

Visible light is the part of the energy generated by the sun, which reaches the surface of the earth and is visible to the average human eye. Technically speaking, this is a spectrum of electromagnetic radiation at wavelengths of between 380 nm and 780 nm.

Visible Light Reflection

The percentage of visible light reflected from the surface of the glass, when the sun shines at right angles to the surface of the glass. The reflection increases as the angle of the sun decreases.

Visible Light Transmission

The percentage of visible light transmitted through the glass when the sun shines at right angles to the surface of the glass. Higher visible light transmission makes a building look more transparent from the outside, and makes the interior lighter and airier, increasing the productivity of retail and educational spaces. However, high light transmission may detract from the restfulness of a space and reduce office productivity by increasing glare on work surfaces and walls, and reducing visibility of computer and TV screens.

Understanding Glass

There are two main glass manufacturing methods for producing the basic flat glass from which all processed architectural or building glass products are made:

- Float – More than 90% of the world’s flat glass is made by the float process. Molten glass, at approximately 1000°C, is poured continuously from a furnace on to a large shallow bath of molten tin. It floats on the tin, spreads out and form a level surface. Thickness is controlled by the speed at which the solidifying glass ribbon is drawn off the bath. After annealing the glass emerges as fire polished product, with virtually parallel surfaces.

- Rolled – The rolling process makes patterned, figured and cast glass products, whereby a semi-molten glass is squeezed between metal rollers to produce a ribbon with controlled thickness and surface pattern.

- Wired, deeply patterned and deeply worked glass products cannot be heat treated

- Toughened glass cannot be subsequently surface or edge worked or cut.

Using the basic float and rolled glass product, permutations of the many glass processing technologies generate an extensive range of glass product performances to meet modern building needs. For example, basic float glass may be clear, tinted or coated glass which can then be heat treated or bent. It can be further printed, laminated and double glazed.

There are, however, some combinations that are not feasible to manufacture. The major restrictions are:

Some combinations are feasible only by specialised manufacture. However given the manufacturing parameters, the permutations are considerable. In order to understand why such permutations are demanded for glazing, the

functions of the window itself also require consideration.

Annealed glass (also referred to as monolithic annealed glass) has been, and still is, the commonest glazing medium used in-building today, in spite of its vulnerability to breakage. However, safety glasses are increasingly being specified, particularly after the introduction of the National Building Regulations SANS 10400: Part N. Ordinary laminated annealed glass is, thickness for thickness, no stronger than annealed (monolithic) glass; its advantage is that broken shards tend to be held by the interlayer and, if recommended glazing techniques have been followed, the glass should be retained until safe removal is possible. Wired annealed glass is weaker than unwired annealed glass of corresponding thickness but, as with laminated, the shards tend to be held. Thermally toughened safety glass is stronger than annealed and laminated glass, both in terms of impact resistance and of thermal stress.

Contribution to Thermal Comfort

Window glass influences occupant thermal comfort by:

- heat gain or heat loss through the glass, which either raises or lowers the room temperature

- radiation exchange between glass and occupant

For an occupant close to a window, the internal glass surface temperature influences thermal comfort as a result of heat loss produced by long wave radiation exchange between the occupant and the window. There may be a marked difference in sensation of comfort between the two sides of the body according to the proximity to and the size of the window, and its surface temperature.

In winter, the glass surface can be much colder than other room surfaces, producing a loss of heat from the occupant’s body surface, by long wave radiation, to the colder glass surface and contributing to a sensation of cold discomfort. In summer, the internal surface of glass can be much hotter, for example owing to the absorption of solar radiation in a body tinted glass. This contributes long wave radiation which, in addition to any direct short wave solar radiation received through the glass, is absorbed by the occupant and contributes to a sensation of hot discomfort.

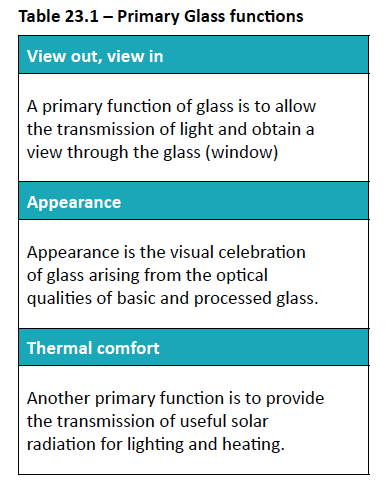

Incurred Glass Functions

In order to achieve the primary functions, the glass must resist the natural forces likely to be imposed upon it, such as wind and weather, and may also be required to keep out man-made attacks such as bullets, vandalism and burglar attack. It must be safe and secure. It must also act as a complicated filter of light, heat and sound energy to optimize efficiently the primary visual and lighting functions.

Standards

Many people think that simply designing a building with windows that can open will naturally ventilate a building and with no real consideration given to the type of glass being used. However this is not true, the design of such buildings requires many mathematical processes and other considerations, for one, energy efficiency. For example, if you are building in Cape Town, where there is a lot of wind, you are dealing with different dynamics to say the Gauteng Highveld where radiant levels are higher.

Fenestration is only one part of many building segments, which determine the overall energy efficiency in a building. The complexity arriving at an overall energy performance of a building is usually the prerogative of a registered Mechanical and/or Electrical Engineer. However, these qualified engineers are not in all instances engaged on all building contracts to evaluate the energy performance of buildings.

It is therefore appropriate that “deemed-to-satisfy” rules are implemented to govern the many building segments ensuring that the overall safety or energy performance of a building meets the required levels. In the event that the “deemedto- satisfy” rules are complied with during the execution of construction, the resulting building will be assumed to meet the safety or energy performance criteria. Only design professionals may deviate from the “deemed-to-satisfy” rules and must give written approval of such deviations.

Previously, installing 3mm or 4mm float glass would have done the job, but with the emphasis on safety and energy efficiency becoming more prevalent, including building ratings, the demand for glazing products that can perform optimally within these parameters has risen. Too often developers attempt to build as many buildings or dwellings, as quickly and cheaply as possible, with little consideration given to long term energy costs because the owner or tenant will pick up the tab.

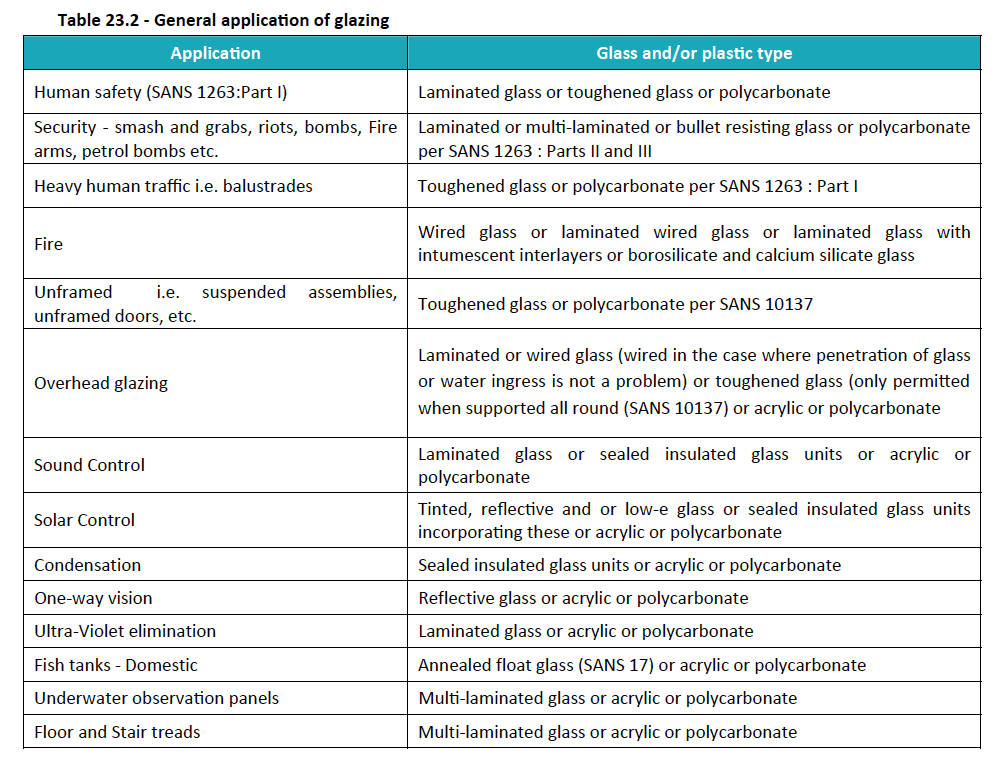

Glass and plastic glazing are usually selected on merits of economics, aesthetics and performance but all glazing is to be executed in strict accordance of the latest editions of the following South African Standards:

- SANS 727, Windows and doors made from rolled mild steel sections.

- SANS 1263-1, Safety and security glazing materials for buildings – Part 1: Safety performance of glazing materials under human impact.

- SANS 1553-2, PVC-U window and door frames for external use – Part 2: Windows with frames made from PVC-U profiles.

- SANS 2001-CG1, Construction works – Part CG1: Installation of glazing in window and door frames.

- SANS 10137 (SABS 0137), The installation of glazing in buildings.

- SANS 10400-A (SABS 0400-A), The application of the National Building Regulations – Part A: General principles and requirements.

- SANS 10400-B (SABS 0400-B), The application of the National Building Regulations – Part B: Structural design.

- SANS 10400-N (SABS 0400-N), The application of the National Building Regulations – Part N: Glazing.

- SANS 10400-XA, The application of the National Building Regulations – Part XA: Energy usage in buildings.

- SANS 50572-1/EN 572-1, Glass in building – Basic soda lime silicate glass products – Part 1: Definitions and general physical and mechanical properties.

- SANS 50572-2/EN 572-2, Glass in building – Basic soda lime silicate glass products – Part 2: Float glass.

- SANS 50572-3/EN 572-3, Glass in building – Basic soda lime silicate glass products – Part 3: Polished wire glass.

- SANS 50572-4/EN 572-4, Glass in building – Basic soda lime silicate glass products – Part 4: Drawn sheet glass.

- SANS 50572-5/EN 572-5, Glass in building – Basic soda lime silicate glass products – Part 5: Patterned glass.

Float, toughened, laminated, wired and patterned glass is currently used in the building industry. Laminated safety glass is currently locally produced using the following manufacturing process.

Laminated safety glass using polyvinyl butyral (PVB) interlayer is supplied in three strengths namely:

- Normal strength (NS)

- High Penetration Resistance (HPR)

- High Impact (HI)

Specifiers and manufacturers must ensure that the manufacturer of any laminated glass provides a warranty of not less than 5 (five) years against Delamination and colour degradation, confirming that the product confirms to that section of SANS 1263 which pertains to the particular application of safety glass i.e., for resistance to human impact (Part I) or to burglary and vandalism (Part II), or to firearms (Part III).

Note: In terms of SANS 1263 Part I glass with applied film (organic coating) is not regarded as a safety glazing material unless it meets all requirements of SANS 1263 Part I (including the boil and artificial ageing tests). In addition, the applied film must cover the entire surface of the glazing material i.e. the film must be retained in the glazing rebate.

Extracts form Part N

Glazing installations

Glazing materials shall comprise either glass that complies with the requirements of parts 1 to 5 of SANS 50572, or polycarbonate sheeting.

Frames to receive glazing material shall either comply with the requirements of SANS 727 or SANS 1553-2, or be capable of withstanding the wind and impact loads determined in accordance with the requirements of SANS 10400-B without deflecting more than 1/175th of their span.

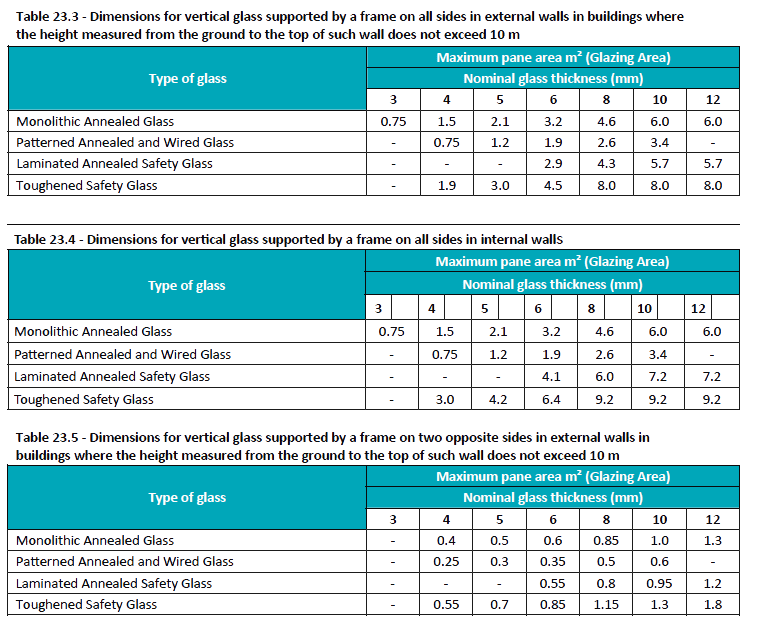

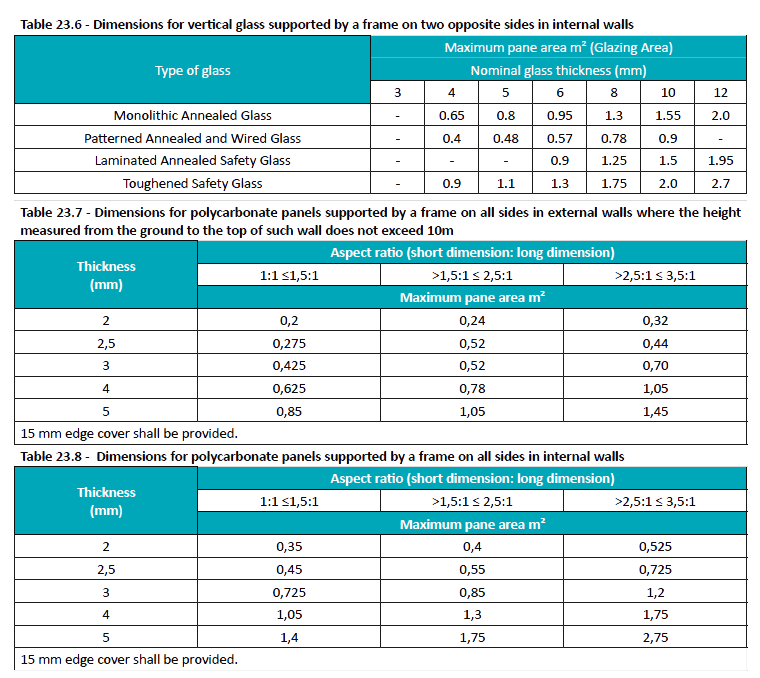

The thickness of panes of glass and flat solid polycarbonate sheeting, other than in lifts, shall

- a) be not less than that given in tables 23.3 to 23.8, or

- b) be determined by a competent person (glazing) in accordance with the requirements of SANS 10137, or

- c) be based on wind loads determined in accordance with the requirements of SANS 10400-B.

Note: SANS 10400-B requires that wind loads be determined by a competent person (structures).

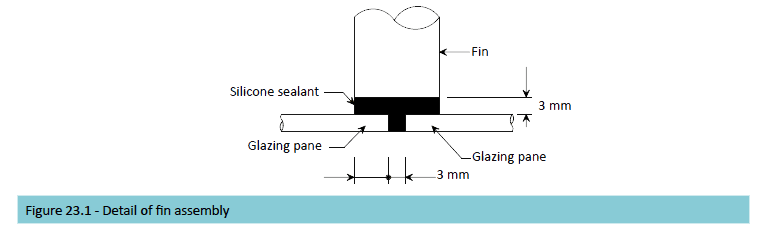

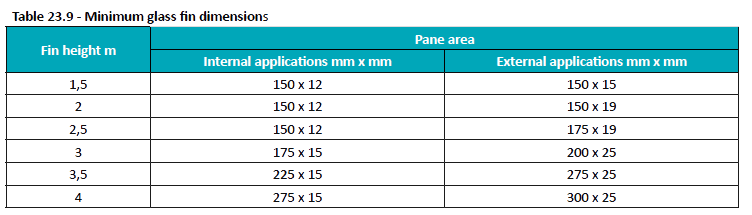

The top and bottom of glass fins (see figure 23.1) installed at butt joints of glass panes shall be fully fixed to the supporting structure and have overall dimensions as given in table 23.9. Silicone sealant that has a tensile strength of at least 1 MPa shall be used.

Note: A butt joint is assumed to have no structural strength. Therefore panels which incorporate a butt joint are not considered to be supported on all sides. A glass fin is necessary to provide the support at the joint so that the pane can be considered to be supported on four sides or on two opposite sides.

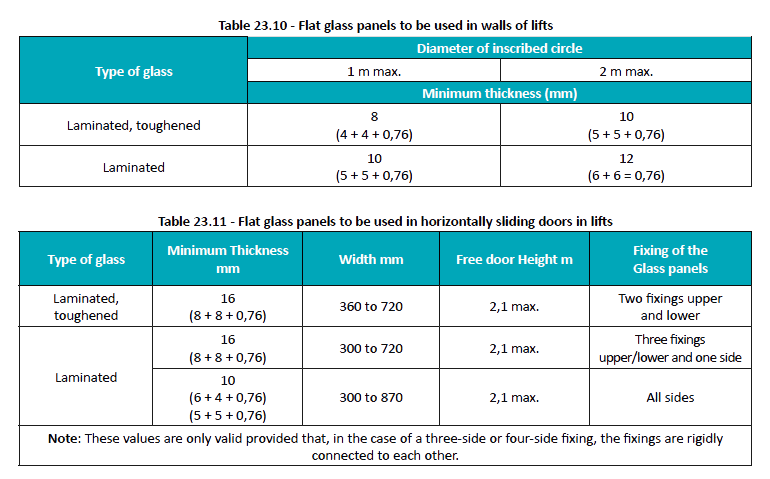

The thickness and type of pane glass panels in lifts shall be in accordance with the requirements of tables 23.10 and 23.11, as relevant.

Recommended glazing thicknesses

Glass selection must be in accordance with the following tables to ensure compliance.

Where transparent glazing is used and is not likely to be apparent to, or suspected by, any person approaching it, such glazing shall bear markings that shall render it apparent to such person.

Safety glazing

In terms of the National Building Regulations, glazing material must provide an appropriate level of protection in the case of human impact. For example, safety glazing is required in doors and entrances, windows, bath enclosures, balustrades, shop fronts, stairways and other areas. The panes of all safety glazing material shall be permanently marked by the installer in such a manner that the markings are visible in individual panes after installation.

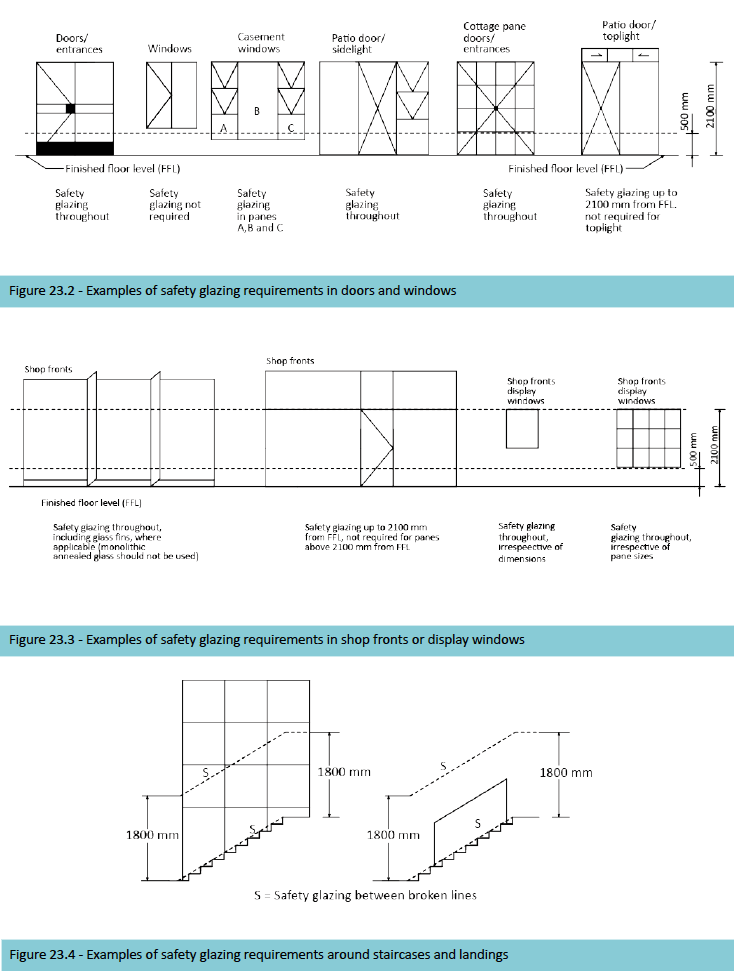

Safety glazing material that complies with the requirements of SANS 1263-1 shall be used where (see figures 23.2 to 23.4):

- a) The occupancy or building classification is A3 (place of instruction), E1 (place of detention), E2 (hospital) and E3 (other institutional (residential) buildings) (see SANS 10400-A);

- b) Doors and sidelights form part of any entrance up to 2 100 mm from finished floor level;

- c) A window has a sill height of less than 500 mm from the floor;

- d) A window has a sill height of less than 800 mm from the floor without any permanent barrier that prevents persons from coming into contact with the glass panel, and is so placed that persons are likely, on normal traffic routes, to move directly towards such window;

- e) A bath enclosure or shower cubicle is glazed or where glazing occurs immediately above a bath;

- f) Glazing is used in any shop front or display window within 2 100 mm from the finished floor level;

- g) Glazing is used in any wall or balustrade to a stairway, ramp, landing or balcony;

- h) Glazing is used within 1 800 mm of the pitch line of a stairway or the surface of a ramp, landing or balcony;

- i) Glazing applications are sloped or horizontal;

- j) A mirror is installed as a facing to a cupboard door less than 800 mm above floor level and there is no solid backing;

- k) Glazing is used around areas such as swimming pools and ice rinks; and

- l) Glazing is used in internal partitions, which are within 2100 mm of floor level.

Glass in balustrades shall be toughened safety glass unless rigidly supported on all sides. Glass in horizontal or sloping applications shall be laminated or toughened safety glass. Toughened safety glass shall only be used where individual panes are framed on all sides.

Wired glass that has two-edged support may be used in vertical glazing in sawtooth roofs.

Note: A barrier could be any feature, i.e. a heavy bar across a window, or a flower box placed in front of the window, that will provide a physical or visual barrier between the glass and a person.

The images that follow (Figure 23.2; 23.3 and 23.4) summarise safety glazing requirements in terms of the standards discussed above.

Note: Glazing to shower doors is discussed under shower doors later in this section.

Extracts form Part XA

Fenestration

Buildings with up to 15 % fenestration area to nett floor area per storey comply with the minimum energy performance requirements.

Buildings with a fenestration area to nett floor area per storey that exceeds 15 % shall comply with the requirements for fenestration in accordance with SANS 204. All fenestration air infiltration shall be in accordance with SANS 613.

Extracts from SANS 204

Fenestration

The air leakage (AL) of external vertical glazing in each storey of a sole-occupancy unit, public space or other occupied space shall be assessed separately in accordance with the standard.

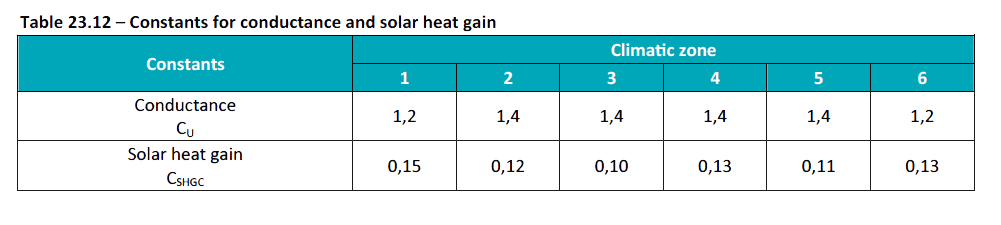

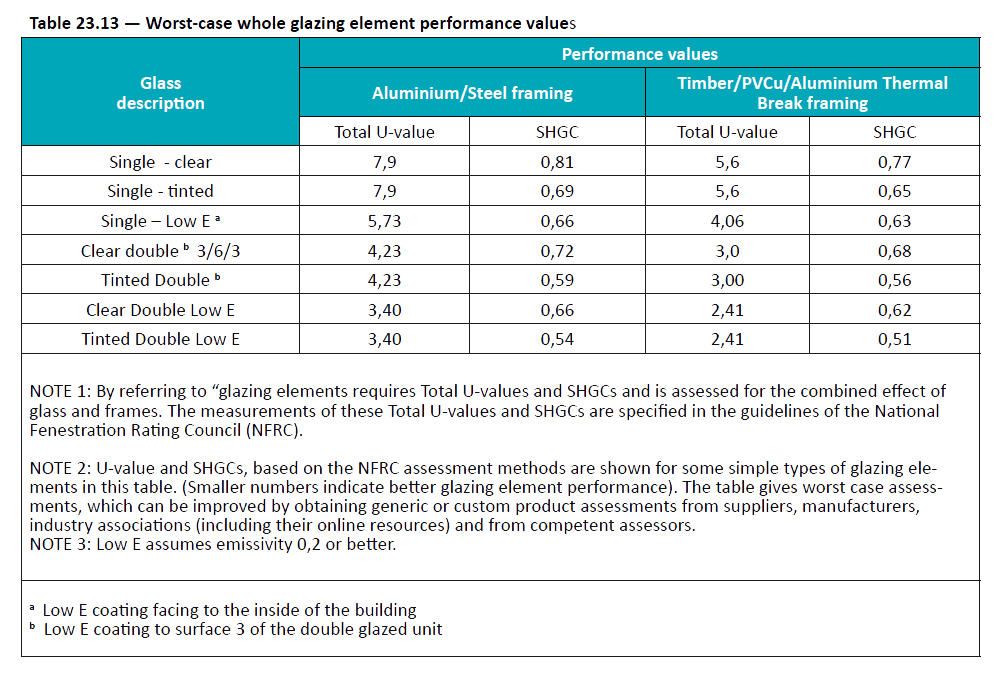

The aggregate conductance and solar heat gain of the glazing in each storey shall not exceed the values obtained by multiplying the net floor area measured within the enclosing walls with the constants CU for conductance; and CSHGC for solar heat gain given in table 23.12.

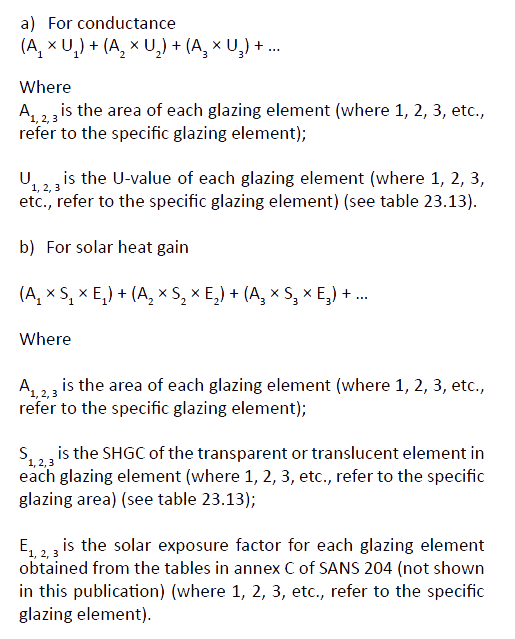

The aggregate conductance and solar heat gain of the glazing in each storey shall be calculated by adding the conductance and solar heat gain of each glazing element to the equations that follow.

The aggregate conductance and solar heat gain of the glazing in each storey shall be calculated by adding the conductance and solar heat gain of each glazing element to the following formulae:

The U-values and SHGC values in accordance with table 18.13 (worst-case glazing element performance), shall be used unless these values are supplied by the glazing manufacturers as verified according to the test method ASTM C 1199 and ISO 9050 for U-values, and given in NFRC 100 for SHGC values.

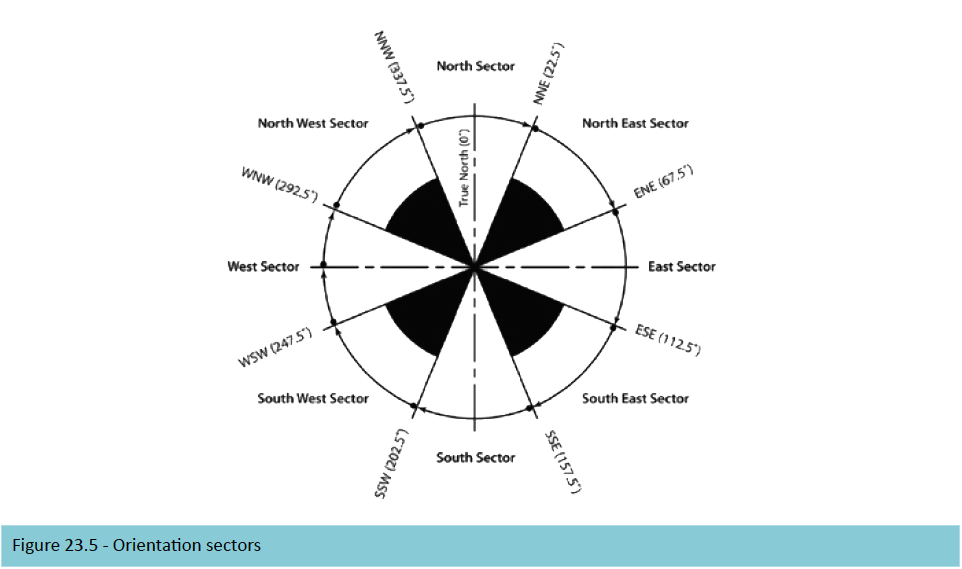

A building wall, including the glazing it contains, shall be considered to face north if it faces any direction in the north orientation sector of figure 23.5. The orientation of other walls, including the glazing they contain, shall be determined in a similar way.

Note: For shading related to fenestration see – roofing section.

Performance of Glazing

Sound insulation

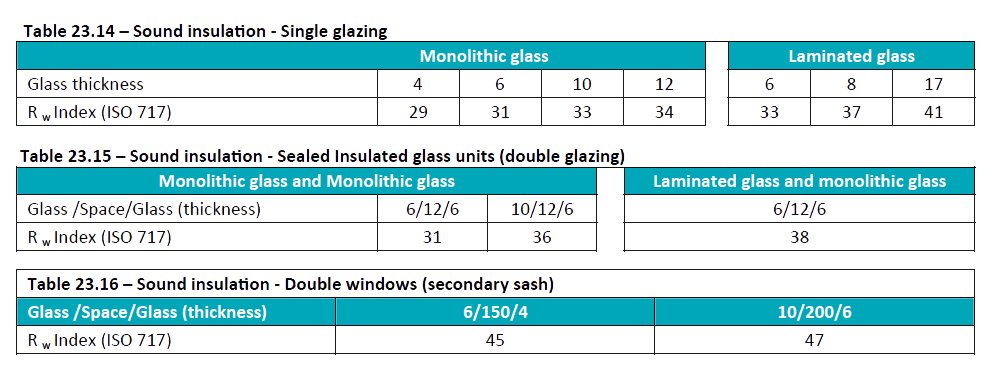

Thickness for thickness, clear float, toughened, wired, coated and tinted monolithic glass products have exactly the same acoustic performance. Conventional single glass frames with double glazing units instead of single glazing, will make only a marginal improvement in sound insulation. The sound insulation performance of an air filled double glazing unit improves only slightly with increasing air space width. Worthwhile improvements in sound insulation will only come from the use of a secondary sash, as seen in the tables 23.14 to 23.16 below.

Energy efficiency

Heat flows through a window assembly in three ways: conduction, convection, and radiation. Conduction is heat travelling through a solid, liquid or gas. Convection is the transfer of heat by the movement of gases or liquids, like warm air rising from a candle flame. Radiation is the movement of energy through space without relying on conduction through the air or by movement of the air, like the way you feel the heat of a fire.

When there is a temperature difference across an object, i.e. when a window separates a cold outdoors from a warm interior or hot outside from a conditioned interior space. Heat transfer will occur via these three physical mechanisms: conduction through glass and solid frame material, convection/conduction through air spaces, and long wave radiation between glass surfaces on either side of an air gap. This temperature-driven heat transfer is quantified by the term U-factor and is discussed in this section on insulating value.

- Long-wave radiation heat transfer refers to radiant heat transfer between objects at room or outdoor environmental temperatures. These temperatures emit radiation in the range of 3-50 microns.

- Short-wave radiation heat transfer refers to radiation from the sun (which is at a temperature of 6000K) and occurs in the 0.3-2.5 micron range. The range includes the ultraviolet, visible, and solar-infrared radiation.

Even though the physical process is the same, there is no overlap between these two wavelength ranges. Coatings that control; the passage of long wave or solar radiation in these ranges, through transmission and/or reflection, can contribute significantly to energy savings and have been the subject of innovation in recent years. Glazing types vary in their transparency to different parts of the visible spectrum e.g. a glass that appears tinted green as you look through it toward the outdoors transmits more sunlight from the green portion of the visible spectrum and absorbs or reflects more of the other colours. Similarly, a bronze-tinted glass absorbs or reflects the blues and greens and transmits the warmer colours. Neutral grey tints absorb or reflect most colours equally.

The same principle applies outside the visible spectrum. Most glass is particularly transparent to at least some ultraviolet radiation, while plastics are commonly more opaque to ultraviolet. Glass is opaque to long-wave infrared radiation but generally transparent to solar-infrared radiation. Strategic utilization of these variations has made some high-performance glazing products. The four basic properties of glazing that affect radiant energy transfer are transmittance, reflectance, absorptance and emittance as described below:

Transmittance refers to the percentage of radiation that can pass through glazing. Transmittance can be defined for different types of light or energy, e.g. visible transmittance, UV transmittance, or total solar energy transmittance. Transmission of visible light determines the effectiveness of a type of glass in providing daylight and a clear view through the window. For example, tinted glass has a lower visible transmittance than clear glass. While the human eye is sensitive to light at wavelengths from about 0.4 to 0.7 microns, its peak sensitivity is at 0.55, with lower sensitivity at the red and blue ends of the spectrum. This is referred to as the photonic sensitivity of the eye.

More than half of the sun’s energy is invisible to the eye. Most reaches us as near-infrared with a few percent in the ultraviolet (UV) spectrum. Thus, total solar energy transmittance describes how the glazing responds to a much broader part of the spectrum and is more useful in characterizing the quantity of total solar energy transmitted by the glazing.

With recent advances in glazing technology, manufactures can control how glazing materials behave in these different areas of the spectrum. The basic properties of the substrate material (glass or plastic) can be altered and coatings can be added to the surfaces of the substrates. For example, a window optimized for day lighting and for reducing overall solar heat gains should transmit an adequate amount of light in the visible portion of the spectrum, while excluding unnecessary heat gain from the near-infrared part of the electromagnetic spectrum.

Just as some light reflects off the surface of water, some light will always be reflected at every glass surface. A specular reflection from a smooth glass surface is a mirror like reflection similar to the image of yourself you see reflected in a store window. The natural reflectivity of glass is dependent on the type of glazing material, the quality of the glass surface, the presence of coatings, and the angle of incidence of light. Today, virtually all glass manufactured in the United States is float glass, which reflects 4 percent of visible light at each glass-air interface or 8 percent total for a single pane of clear, uncoated glass. The sharper the angle at which the light strikes, the more the light is reflected rather than transmitted or absorbed. Even clear glass reflects 50 percent or more of the sunlight striking it at incident angles greater than 80 degrees. The incident angle is formed with respect to a line perpendicular to the glass surface.

The reflectivity of various glass types becomes especially apparent during low light conditions. The surface on the brighter side acts like a mirror because of the amount of light passing through the window from the darker side is less than the amount of light being reflected from the lighter side. This effect can be noticed from the outside during the day and from the inside during the night. For special applications when these surface reflections are undesirable, i.e. viewing merchandise through a store window on a bright day, special coatings can virtually eliminate this reflective effect.

Most common coatings reflect in all regions of the spectrum. However, in the past 20 years, researchers have learned a great deal about the design of coatings that can be applied to glass and plastic to preferentially reflect only selected wavelengths of radiant energy. Varying the reflectance of far-infrared and near-infrared energy has formed the basis for high performance low –E-Coatings.

Energy that is not transmitted through the glass or reflected off its surfaces is absorbed. Once glass has absorbed any radiant energy, the energy is transformed into heat, raising the glass temperature.

Typical 6mm clear glass absorbs only about 7 percent of sunlight at a normal angle of incidence. The absorptance of glass is increased by glass additives that absorb energy. If they absorb visible light, the glass appears dark. If they absorb ultraviolet radiation or near-infrared, there will be little or no change in visual appearance. Clear glass absorbs very little visible light, while dark-tinted glass absorbs a considerable amount.

The absorbed energy is converted into heat, warming the glass, thus, when “heat-absorbing” glass is in the sun, it feels much hotter to touch than clear glass. Tints are generally grey, bronze, or blue-green and were traditionally used to lower the solar heat gain coefficient and to control glare. Since they block some of the sun’s energy, they reduce the cooling load placed on the building and its air-conditioning equipment. The effectiveness of heat-absorbing single glazing is significantly reduced if cool, conditioned air flows across the glass. Absorption is not the most efficient way in reducing cooling loads.

All glass and most plastics, however, are generally very absorptive of long-wave infrared energy. This property is best illustrated in the use of clear glass for greenhouses, where it allows the transmission of intense solar energy but blocks the retransmission of the low-temperature heat energy generated inside the greenhouse and radiated back to the glass.

When solar energy is absorbed by glass, it is either converted away by moving air or reradiated by the glass surface. This ability of a material to radiate energy is called emissivity. Window glass, along with all other objects, typically emits, or radiates, heat in the form of long-wave far-infrared energy. The wavelength of the long-wave far-infrared energy varies with the temperature of the surface. This emission of radiant heat can greatly improve its insulating properties.

Standard clear glass has an emittance of 0.84 over the long-wave infrared portion of the spectrum, meaning that it emits 84 percent of the energy possible for an object at room temperature. It also means that for long-wave radiation striking the surface of the glass, 84 percent is absorbed and only 16 percent is reflected. By comparison, low-E glass coatings have an emittance as low as 0.04. This glazing would emit only 4 percent of the energy possible at its temperature and thus reflect 96 percent of the incident long-wave infrared radiation.

There are four properties of windows that form the basis for quantifying energy performance:

- U-factor – when there is a temperature difference between inside and outside, heat is lost or gained through the window frame and glazing by the combined effects of conduction, convection, and long-wave radiation. The U-factor of a window assembly represents its overall heart transfer rate or insulation value.

- Solar heat gain coefficient – Regardless of outside temperature, heat can be gained through windows by direct or indirect solar radiation. The ability to control this heat gain through windows is characterized in terms of the solar heat gain coefficient (SHGC) or formerly known as the shading coefficient (SC) of the window.

- Visible transmittance – or (VT), also referred to, as visible light transmittance (VLT), is an optical property that indicates the amount of visible light transmitted through the glass. It affects energy by providing daylight that creates the opportunity to reduce electric lighting and its associated cooling loads.

- Air leakage – Heat loss and gain also occur by air leakage through cracks around sashes and frames of the window assembly. This effect is often quantified in terms of the amount of air (cubic metres per minute) passing through a unit area of window (m²) under given pressure conditions.

These four concepts as well as Light-to-Solar-Gain ratio, a ratio of VT/SHGC have been standardized within the glazing industry allowing an accurate comparison of windows.

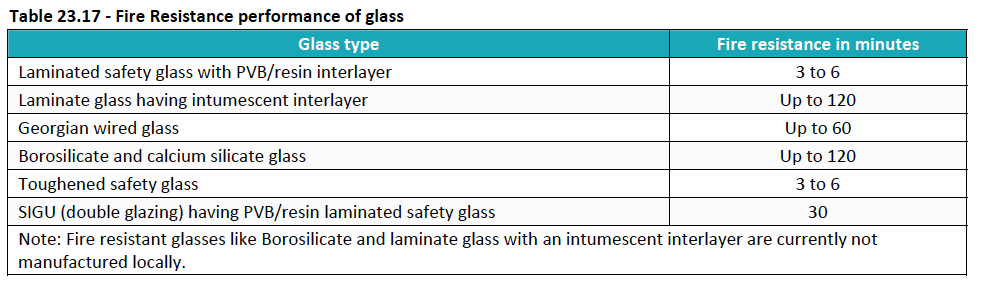

Exposure to fire

Window manufacturers, building contractors, sub-contractors and glaziers are not fire experts and it is therefore the responsibility of the client or their agents; being the architect or engineer or a competent person (fire) who will specify and indicate the glass requirements, in respect of location and degree of resistance to fire (see table 18.7 below).

Framing required for fire resistance in excess of 30 minutes must be manufactured in steel or hard wood of appropriate volume; aluminium framing will not resist fire when tested in accordance with SANS 10177 in excess of 30 minutes.

When tested in accordance with SANS 10177 glazing materials may perform as stated in the table below.

Note: Glass and polycarbonate flat sheet in and on itself is not fire resistive unless installed in a proper frame, with all the elements i.e. Glass, framing, sealants/ gaskets, anchorage, and installation quality being done in accordance with the prescribed standard.

Types of Glass

Float /Annealed

Float/annealed window glass has a smooth surface on both sides, which is the way the product is finished as it comes off the float line; flame polished and annealed. This glass is also available in obscure and different colours (see patterned glass). Float glass is vulnerable to breakage and will break when subjected to a severe blow or load, when broken slivers of large pieces may cause injury. Clear float glass of 3, 4 and 6 mm thick is the most commonly used glazing medium.

Float /annealed glass is subject to building regulations that govern the thickness relative to the size of a pane. These regulations are covered under standards. Float glass is manufactured by PFG Building Glass, the only float glass manufacturer in sub-Saharan Africa.

Laminated

Ordinary laminated glass is thickness for thickness, no stronger than annealed glass; its advantage is that broken shards are usually held together by the interlayer and, if recommended glazing techniques have been followed, the glass should be retained until safe removal is possible. Laminated glass for domestic work is commonly made with two sheets of float/annealed glass laminated together under heat and pressure with a polyvinyl butyral (PVB) interlayer.

Laminate sheet glass is available in many varieties, which it is not practical to list in detail here, though they range from methods of strengthening (toughening, laminating and wiring) to coatings to alter the light and heat transmission characteristics e.g. low E, and surface patterning and modeling. (See feature glass)

Toughened

Normal annealed glass (float glass) which has been converted into structural glass by process of heating and rapid cooling. The process producers a glass 4 to 5 times stronger, than normal annealed glass of the same thickness. Toughened safety glass (the strongest type of glass available) is more resistant to impact and thermal shock than annealed glass. Toughened safety glass will disintegrate into small harmless pieces or fragments with blunt edges on impact.

Toughened safety glass is ideal for bolted structural glazing and frameless applications. Superb resistance to thermal stress also allows toughened safety glass to be used in applications such as refrigerator and oven doors, where ordinary annealed glass would be likely to fracture. Toughened safety glass is available in a range of thicknesses and various colours.

Patterned

Patterned glass is manufactured as the glass ribbon passes between rollers; the pattern/design is pressed onto one surface of the glass. By changing the one roller, different patterns are achieved. This glass has the same break pattern properties as normal float/annealed glass. Patterned glass obscures a view without noticeable loss of natural or artificial light and available in a range of textures, making it possible to achieve the desired functionality with a decorative effect that complements the aesthetic environment.

There are variations in obscurity between different patterns:

- A = low obscurity

- B = medium obscurity

- C = high obscurity

Feature or architectural

These types of glass sheets are available in many varieties from coated monolithic products offering superior thermal insulation properties to silk-screened, coloured, and custom-manufactured ranges to decorative laminated ranges. (For more details, see products available.)

Wired

Flat window glass reinforced by embedded wire mesh, which holds the pieces together if it breaks, and normally used as a fire-resistant glass. Wired glass is usually more brittle than normal glass of same thickness; often referred to as Georgian wired glass.

Bullet proof

High grade security glazing typically manufactured with a varying number of interlayer’s as a multi-laminated glass, available in thicknesses from 20 to 200mm or as a glass-polycarbonate composite.

Double-Glazing

Double glazing is not a matter of two pieces of glass just being put next to each other – Double glazing is a fabricated sealed unit installed in a frame. It is also often wrongly assumed that double glazing is only for cold climates. In fact, the best performance levels in both U-value and SHGC can only be achieved by using doubleglazing.

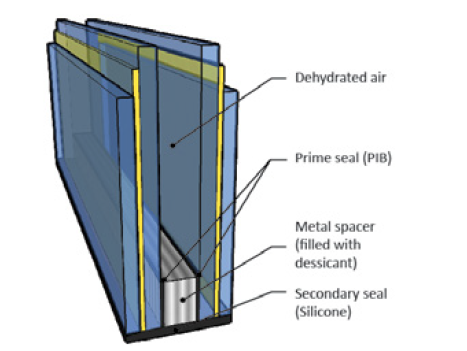

Double glazing facilitates higher performance for all climates, especially in heated and air-conditioned buildings or homes. Multiple layers of glass can be assembled with sealed cavities between each sheet, which is commonly referred to as double or triple glazing but is now increasingly being referred to as a Sealed Insulating Glazing Units (SIGU) – See following figure.

The performance of SIGUs depends on the properties of each layer of glass and the thickness, sealing and content of the cavities between the glass layers.

Using combinations of standard and low-e glass allows SIGU to be tailored to have extremely low U-values ranging from 3.5 to as low as 1. Using clear, toned, reflective or low-e glass can deliver a wide range of SHGC values from 0.2 to 0.7. However in housing, good daylighting is invariably required; in this situation only a double-glazed configuration will simultaneously achieve very low SHGC values coupled with high VT.

The performance of the cavity in SIGUs impacts on the U-value and serviceability of the glazing. Cavities must be sealed to minimise convective heat transfer. If the cavity is not properly sealed or contains inadequate desiccant it may contain moisture which, under cold conditions, will condense on the colder glass surface. The spacer (metal or polymer strip) that separates the two glass layers contains a desiccant to absorb any moisture. SIGU cavities may also be filled with an inert, low-conductivity gas such as argon. Cavity thickness is usually in the range 6 to 18mm. wider cavities provide lower (better) U-values with 12mm normally accepted as the preferred gap.

Note: The term used to describe the surfaces of the glass in numerical order from the exterior to the interior. The exterior surface is always referred to as face 1. For a double-glazed unit, the surface of the outer pane facing into the cavity is face 2, the surface of the inner pane facing into the cavity is face 3 and the internal surface of the inner pane is face 4. With triple glazing there will be a face 5 and 6, with face 6 becoming the roomside face.

Types of Plastic

Plastic glazing materials are less prone to breakage than glass, but most are softer and more liable to surface damage such as scratching. They may also have quite large thermal movements. Those most commonly used are polycarbonate and acrylic.

Polycarbonate

Polycarbonate is not prone to discolouration so much as surface erosion due to weathering. This tends to lead to loss of surface gloss and reduction of clarity of transmitted images. Polycarbonate has relatively good retention of impact resistance and dimensional stability on weathering. Surface coated varieties are available with significantly enhanced weatherability.

Acrylic

Acrylic sheet (polymethyl methacrylate) has very good retention of optical clarity on exposure to weathering but can be prone to crazing and embrittlement in the long term, especially when subjected to undue stress.

Curtain Walling

Curtain walling, and its derivative, the so-called but confusingly named ‘structural glazing’, is undoubtedly a development of the twentieth century. The true curtain wall has no load bearing function other than to carry its own loads, to transmit the wind loads on the face of the wall to the primary framed structure behind and to offer weathertightness against driving rain. The industry is imprecise about the definition of curtain walling.

However, for the purposes of definition, it is taken to be a form of cladding with glazing contained within or superimposed on a grid of framing members, with the majority of its surface area consisting of glazing.

The main impetus behind its development came with the need to reduce the dead loads on high-rise office buildings, while at the same time, saving space and providing an external skin, which met all the necessary functional requirements.

Curtain walling systems may be prefabricated off site into assembled frames complete with infilling allowing the early enclosure of the building, or may be built up on site from separate framing members and infill panels. Installation usually involves no wet trades, whether they are unit systems, placed by crane, or ‘stick systems’ assembled on site from inside the building or from a flying scaffold. Site assembly, provides more opportunity for adjustment of dimensions to fit the structure, but at the same time more opportunity for deficiencies in workmanship leading to deficiencies in performance.

Shower Doors

Plan sizes of 800 mm x 800 mm and 900 mm x 900 mm are the most common. There are many different materials and designs for shower surrounds; they include curtains, tiling of the wall surfaces, glazed screens and various different types of doors. A tray height of 150 mm is considered to be a practical minimum, either set into or standing on the floor plane. Some shower units are supplied as an integral enclosure, which includes the floor tray.

Standards

This standard specifies requirements for shower enclosures for domestic purposes, which ensure that the product, when installed in accordance with the manufacturer’s installation instruction, gives satisfactory performance when used as intended. This standard does not apply to shower cabinets or curtains and does not specify aesthetic and dimensional requirements.

For the purpose of this standard, the following definitions apply:

Shower enclosure – An arrangement of fixed and moving panel(s) and/or door(s) erected on or around a drained shower place, shower tray or bath, either freestanding or in conjunction with one or more walls of the main building structure to provide a water retaining area for the purpose of showering.

Shower cubicle – A prefabricated but not necessarily preassembled unit for the purpose of showering comprising a shower tray or bath and rigid water resistant enclosing wall(s), with or without a roof and with an entry capable of being closed to provide a fully enclosed compartment.

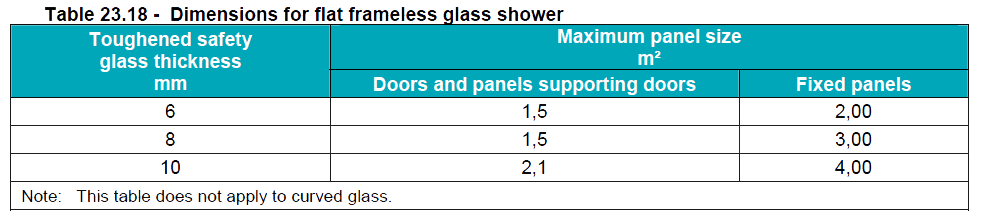

The thicknesses and maximum panel dimensions of frameless bath and shower enclosures shall be as given in table 23.18.

References

Alexander G D & Alexander G C. 2010. Buildaid Building and Pricing Guide 2010/11. Johannesburg: Buildaid Publishing.

Alexander G D & Van As F. 2008: Civil Technology. Johannesburg: EWA Publishing

South African Bureau of Standards – SANS 10400 Part N & various other standards. Pretoria. SABS Standards Division.