Chapter 26

FLOORING

Introduction

Terminology

How to Choose Flooring

Flooring

Introduction

Although books on flooring from a holistic approach are few, there is no shortage of industry guidance on floors and flooring. The problem is that people do not use the guidance that exists. It is our intention to try to bridge that gap with this publication and this section on floors and flooring. Flooring should not merely be viewed as a necessity, but rather as a functional element. The features and functions of floors and flooring in combination are critical when deciding on what type of flooring would best suit the application. We describe the underlying structure to enable an understanding of the behaviour of the whole floor without going too far into engineering design principles.

The contents of this section are configured so that the principles, features and functions of floors and flooring are described first with reference to other sections in this book, to provide an overall understanding of floors and flooring.

Flooring is a diverse area of the building industry because there are so many types and products one can use. Therefore, we have tried to illustrate what to look for as good and bad features of floors and flooring and the type of flooring that would be “fit for purpose” or best suit the application. It also offers sources of further information and advice.

Flooring can assist in demarcating areas, assisting with the flow of traffic into various areas, and can be a striking design tool. Flooring should be practical and functional e.g., a children’s playroom would be easier to clean if it were tiled or fitted with a jointless floor finish, rather than a soft pale coloured carpet

Terminology

Floating floor

A concrete screed, or floorboards, on top of a structural floor (sub-floor), separated from it by resilient material e.g. expanded polystyrene. Its advantage is to reduce transmission of impact noise downwards through a separating floor; typically, a floating floor is not fixed to the sub-floor. A domestic floating floor might be constructed over an existing floor, which would usually consist of a glass fibre, felt or cork layer of sound insulation with neoprene pads holding up a wood floor. There is a gap between the floor and the walls to separate them and allow for expansion, this gap will usually be covered by a skirting or other moulding. Laminate flooring is often referred to as a floating floor.

Floating screed

A screed layer placed on a separation sheet and having gaps between the screed and abutments to separate them and allow for expansion; this gap is usually filled with a Polysulphide sealant.

Floor

A level indoor area for walking on or as some describe as all the horizontal elements of a building (excluding roofs but including ceilings); A floor is one element of the building structure and usually made of concrete or timber.

Floor boarding

A floor made of floorboards laid several boards at a time, tightened with floor cramps and nailed into each joist. The most usual timber boards used for this type of application are 22 x102mm or 22 x138mm tongued and groove boards.

Floor check

A door closer with a hydraulic check, set into a deep hole in the floor, usually covered with a neat brass or chrome plate flush with the finished floor surface.

Floor coverings

Thin resilient floor finishes, usually detachable or loose and laid on top of the finished floor, to improve comfort and reduce impact noise, e.g. carpet, linoleum, and vinyl.

Floor finish

Material laid on top of the sub-floor to form the visible surface and to resist wear. In wet areas, it should be non-slip. It can be in-situ granolithic, thick floor tiles on adhesive or mortar bedding, thin floor finishes, or one of many flooring or floor coverings.

Flooring

Simply refers to the finish of the upper or walking surface of the floor.

Floor joist

A common joist of a timber framed floor, carrying the flooring

Floor paint

Tough paint usually based on epoxy or acrylic resin for the decorative colouring of concrete or timber floors, also capable of acting as a floor sealer.

Floor sealer

A finish either based on polyurethane to keep timber flooring clean, or based on epoxy resin for dust proofing and to improve durability of concrete.

Floor tile

Floor tiles are available in a number of different finishes from glazed ceramics, burnt clay, precast concrete, natural stone etc. In general, wall tiles are too weak, soft, and slippery when wet for use as floor tiles.

Topping

An in situ material laid to provide good abrasion resistance and to provide the wearing surface of a floor. It can also be referred to a cementitious mix used to lock together components of a structural concrete floor, such as hollow blocks, where it is called a structural topping.

Underlay

Is a layer used between the structural deck or slab and the flooring, either prefabricated e.g. underfelt, plywood or hardboard or a thick in situ layer e.g. mastic asphalt or plastic sheeting.

Wear

Is the progressive loss from the surface of a material or component brought about by mechanical action.

How to Choose Flooring

Step 1

The first task of the specifier is to identify the separate areas of the building having specific performance requirements for flooring. Particular attention should be paid to substrates and whether they may be subjected to deflection or movement e.g. prefabricated suspended floor slabs, the risk of and effects of impacts, and the existing and potential ambient conditions in each area of the building; also, how much thickness can be allowed for the finish. In addition, is there a combination of different levels required to suit different flooring types?

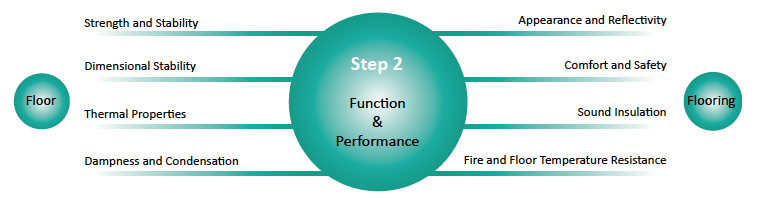

Step 2

Step 3

The specifier will need to set the criteria of the acceptable performance requirements for each of the chosen functions above (where applicable) as some do not necessarily apply to certain applications. Some functions are easier to assess than others are e.g., slip resistance, surface hardness and impact resistance will be easier to deal with than colour and pattern.

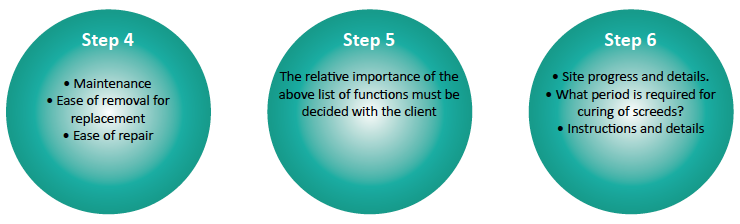

Step 4,5 & 6

Step 7

This final step is assessing and tabulating the above information for comparison of the competing floorings with the performance requirements as described in step 2 (which we discuss in detail below) and decide which flooring would best suit the application or “fit for purpose”. Part of the decision making process should include inspection or research on how similar materials have performed in similar situations and or applications.

Flooring

Appearance and Reflectivity

User satisfaction with floors depends largely on the condition of the top wearing surface. After installation, the surface should be clean and capable of being maintained in this condition. It should be suitable to receive a floor covering if one is not provided under the building contract. In areas where water may spill onto floors, both the effect of moisture on the floor and the ease with which the floor may be cleaned and dried, together with its subsequent rate of deterioration, will need to be considered.

Appearance

The appearance of a floor finish is often considered to be of paramount importance, both in its initial selection and its acceptability for continuing use. The visual acceptability of the various kinds of floor finishes, in the final analysis, is a matter for individual taste and judgement.

Reflectivity

The reflectance of the flooring will affect the amount and distribution of light in a space. After all, in a reasonably sized space most of the light from windows, roof lights and light fittings will fall on the floor. A light coloured floor will increase the illuminances on walls and, especially, the ceiling, making the room look less gloomy and reducing glare from overhead light fittings. In a day lit space the light levels away from the windows, and hence the overall balance of light in the room, will be improved if floor reflectance is increased. Therefore, reflectance values will always need to be considered when choosing floor coverings. However, external reflectivity can be quite the opposite in that when using a very light shade of tile e.g. light grey, it would be almost impossible to look at the floor when exposed to direct sun.

Concrete Wearing Surfaces

This sub-section deals only with floors where the concrete is finished to form the wearing surface i.e. to take traffic directly. The surfaces of slabs, which receive no further applied finish, are normally finished by one of two methods:

- power floating

- hand trowelling or power trowelling

- grind and polish concrete

These methods, if applied to specification are capable of providing satisfactory wearing surfaces. Traditionally, plain concrete was used to provide floors in a wide range of buildings e.g. workshops, stores and warehouses. Most plain concrete floors have sufficient abrasion resistance to withstand foot traffic and light to medium loads. (Also see Polished Concrete below).

Wear resistance

Abrasion resistance varies between poor and very good depending on the type of aggregate, mix, curing, finishing etc. Impact resistance is normally good and long-term resistance to indentation very good. Wear resistance is greatly influenced by the quality of finishing and the strength of the concrete to produce a dense, tight surface layer. Good power floating, followed by power trowelling, can greatly enhance the wearing qualities of a concrete floor.

Slip resistance

The slip resistance of smooth concrete surfaces is fair to good, depending on surface characteristics. Surfaces are slippery when wet unless a textured finish is applied or slip resistant aggregates are used.

Control of damp and condensation

Concrete is unaffected by water and can be used, therefore, in wet areas, provided no chemicals are present in the water.

Thermal properties – “Warmth to touch”

Very poor

Fire

Non-combustible and no flame spread.

Suitable for all likely temperatures, but concrete will be adversely affected by accelerated drying shrinkage, which must be taken into account at the design stage.

Sound insulation

Sound absorption is very poor. Sound insulation depends largely on the mass of the structural floor.

Durability

Cement concrete surfaces have the following chemical resistances to various liquids:

- water: very good

- organic acids: poor

- hydrochloric acid: very poor

- sulphuric acid: very poor

- nitric acid: very poor

- alkalis: good

- sulphates: poor

- mineral oil: good, but will stain

- animal oil: poor

- organic solvents: good

Deterioration in concrete surfaced floors usually results from:

- badly graded aggregate in the concrete

- inadequate control of concrete mix proportions

- too much water in the concrete mix

- inadequate curing of the concrete

Maintenance

It is difficult to maintain concrete surfaces in anything resembling their original appearance since even the densest concrete will absorb liquids and become stained. Scrubbing with hot water and detergents will remove dirt. The surface may be sealed with a hardening agent or a resin from time to time to prevent or reduce staining and dusting (see paints and seals below).

Polished Concrete

HTC Superfloor™

Concrete, known in Rome by its Latin name concretus, has become synonymous throughout history with strength and durability. HTC Superfloor™ is the revolutionary flooring concept that uses a technique that makes concrete more than just strong and hard-wearing. The technique is as simple as it is ingenious. HTC’s machines and diamond tools grind and polish concrete floors to remove the surface paste and expose the stronger concrete beneath. The result of this process is a stronger, more durable, shiny and beautiful polished concrete floor. The environment and one’s bottom line both benefit too.

Concrete floors deserve better treatment than just being walked on. An HTC Superfloor™ will make one appreciate the advantages of having concrete as an exposed floor surface. Dirty, grey concrete floors are transformed into brilliant, easy to clean, environmentally-friendly and durable polished concrete floors.

New or existing floors

HTC Superfloor™ finish can be used on both existing concrete floors with or without coatings and for new buildings in the construction phase. For existing floors, the final appearance is dependent on how the concrete floor was made with regard to the colour of the cement, the type and amount of aggregate used and how much of the aggregate it is possible to expose after grinding. Existing concrete floors can often be ground to the quality of a HTC Superfloor™ using diamond tools and concrete polishers from HTC. For newly cast concrete floors, the different possibilities for creating an elegant floor are endless.

Beauty comes from below

Floors are an important part of everyday life, in both industrial areas and private residences. But as well as looking good, a floor needs to be functional too. That’s why one will like HTC Superfloor’. The glossy concrete surface is not just aesthetically pleasing – it brings a host of other benefits too.

Strong floor, strong bottom line

HTC Superfloor’” is an extremely economical option for all types of business activities. Compared with traditional methods for concrete floors or epoxy, for example, HTC Superfloor” offers unbeatable durability. The processed construction concrete has an unlimited lifespan, i.e. the same as the lifespan of the building. The initial investment is the same, or lower, than for traditional flooring solutions, but the low maintenance cost and the longer lifespan make HTC Superfloor” the most lucrative investment option. The life cycle cost is about 60% less than for traditional flooring solutions. And using the Twister’” method of cleaning, the floor is simple, environmentally-friendly and cost-effective to maintain.

Concrete is composed of pure natural materials. The coatings that are often applied to the concrete have an adverse effect on the environment. HTC Superfloor’” uses as much as 30 times less energy than traditional flooring solutions. The Twister” floor maintenance system is also the only completely eco-friendly cleaning method. Twister” uses nothing but ordinary water, no chemicals!

A floor to suit all tastes

HTC Superfloor’” is available in four different concepts. Platinum, Gold, Silver and Bronze. This means one can choose between a floor with a matt finish or a high gloss finish. What all four of the HTC Superfloor’” concepts have in common is that they are functional, economical, eco-friendly and aesthetically appealing.

A floor for the electronics industry

The resistance tests conducted, both on floor joists and on concrete slabs on the ground, show that HTC Superfloor’” complies with the SS-EN 61340-5-1 standard. Measured values fall within the range for the international IEC standard and the American ANSI/ESD standard too. Walk-around tests with ESD shoes generally produce low or no static. The limits stipulated in the standard for the handling of electronics have not been exceeded by HTC Superfloor’” in any cases.

Add colour to a floor

HTC Superfloor’” offers more than just a chance to have a hard-wearing, high-gloss floor. One can also add colour with many colours to choose from without losing any of the floors excellent qualities. One might want to bring colour into an entire room or simply incorporate an eye catching logo. Only use water The HTC Twister’” cleaning method allows one to keep all kinds of floors clean with a minimum of effort. All that is required is water – no chemicals or polishing agents.

Polymer Modified Cementitious Screeds

These screeds are commonly used where thin toppings of around 8–10 mm are laid directly onto concrete bases, although they can range in thickness up to 40 mm. They normally have good bond strength to the concrete base and good abrasion resistance. Chemical resistance is enhanced by the incorporation of polymers. (Polymerisation is The chemical process, normally with the aid of a catalyst, to form a polymer by bonding together multiple identical units (monomers))

Aggregates and binders may comprise a variety of materials. The most common aggregates found will be sand and fine granite or other stone chippings like quartz. In addition, shrinkage compensation additives are used to reduce the bond line stresses and minimize shrinkage cracking.

While these screeds are often laid as wearing surfaces, they can be used to receive other floorings. They are useful in making up thicknesses of between 10 and 25 mm, and in forming coves and skirtings.

Appearance

Appearance depends largely on the aggregates, fillers used and colour chosen. Surfaces are sometimes ground to expose decorative aggregates. They can become drab in the absence of suitable maintenance. Bitumen modified cements are usually black or very dark grey. Modified screeds which are grey in colour can easily be mistaken for other cementitious materials not containing polymers.

Strength and stability

Resistance to indentation is usually good, but the bitumen mixes may only give fair performance. Overlatexing can lead to a softer screed with reduced indentation and abrasion resistance. Since many of these floorings are laid relatively thinly, the bond strength to the base can be critical.

Wear resistance

Resistance depends largely on the aggregate or filler, though most mixes will give good performance. Higher proportions of latex in the latex modified mixes will give improved wear resistance up to the point where the material softens.

Slip resistance

The slip resistance of surfaces is normally very good, depending on additives. Bitumen modified mixes are slippery when wet unless a textured finish is applied or slip resistant aggregate used.

Although the finishes are all relatively impervious to water, they cannot be regarded as equivalent to Damp Proof Membranes. Just how impervious depends on the type and amount of polymer incorporated. PVA modified mixes are less resistant to water than natural latex modified mixes, but are more resistant to oil. Bitumen modified mixes are susceptible to softening by oils and greases.

Thermal properties – “Warmth to touch”

Fair

Fire Non-combustible

Suitability for underfloor heating

Suitable Sound insulation

Sound absorption is very poor. Sound insulation depends largely on the mass of the structural floor. Modified screeds can be used in a floating floor; performance depends on overall thickness of the screed.

Durability

Plasticizer migration may occur if these products are used below flexible PVC floorings and too much latex has been added to the mixture. Bitumen emulsion cements should not be used as screeds immediately below sheet and tile flooring. Instead, they should be separated by laying 3 mm of a suitable underlay on top of the screed.

Maintenance

Washing, using a mild detergent is the preferred method of cleaning. Scrubbing should be avoided. Ground surfaces of the latex modified mixes can be polished with a wax emulsion. Solvents should be avoided.

Common Products

Common products are self-smoothing/levelling, cement based, polymer modified, non-structural floor screeds for use over poured in-situ and precast concrete floors, where a smooth, wear resistant surface is required which may be covered by resin overlays, carpet, vinyl, ceramic tiles or natural stone. Only water needs to be added on site to the desired consistency for pumping or manual installation.

Granolithic & Cementitious Wearing

Screeds (Topping)

Standard sand and cement screeds are not usually considered suitable as wearing surfaces. However, if they are laid slightly wetter than normal levelling screeds (i.e. not semi-dry), they can provide moderate abrasion resistance. The addition of small amounts of 10 mm single sized aggregate to the mix will enhance the wear properties and reduce drying shrinkage problems.

Granolithic flooring is still used in residential type projects, where power floating is impractical. A typical example is in the garage.

Granolithic wearing surfaces can be found in two forms:

- As an integral topping to an ordinary concrete mix, laid before the base has achieved initial set – known as monolithic construction. And usually aided by what is termed as dry shake flooring (see below)

- As a separate granolithic screed – known as bonded

screeds and toppings, which are applied to hardened

concrete floors Standard sand and cement screeds are

essentially light-duty flooring elements and are suitable

for the following applications:- Wearing surfaces of floors of utility rooms in domestic premises e.g. store rooms.

- Floors covered with carpets, plastic tiles or linoleum, etc. and subjected to relatively light traffic such as in residential homes and offices.

Note: The concrete on which the granolithic screed or topping is to be laid should be hard and strong i.e. characteristic strength of at least 20 MPa. Weak, friable concrete is not suitable as a base for a screed or topping as the achievement of adhesion between such material and the screed or topping is not possible.

When laid as a topping on fresh concrete (monolithic), thicknesses are about of 15–25 mm. The recommended thickness of bonded screeds and toppings is between 25 and 40 mm. Granolithic screeds exceeding 40 mm are much more likely to debond and become hollow because of drying shrinkage.

Dry Shake Flooring

Dry Shake Flooring Systems are characterized by the application of the dry powder to the surface of freshly laid concrete. The special hydraulic cements and powerful workability aids in the powder release moisture from the concrete. This results in the material hardening at a very low water-cement ratio, monolithically with the base concrete, creating an integral and extremely hardwearing surface.

Dry Shake Flooring Systems are cost effective as they are installed with the main floor slabs by the same concrete flooring contractor. Since there is no separate installation process, they have no effect on the programming of a project.

Appearance and reflectivity

- Some granolithic surfaces may have been coloured by the use of coloured cements or pigments, and some may be of a colour imparted by the colour of the fine aggregate used. Reflectivity therefore depends upon the surface colour chosen, lighter shades like grey give reflectances of around 0.45, with darker shades being around 0.25.

- Wear resistance is the prime requirement for granolithic toppings. Abrasion resistance is good to very good depending on the type of aggregate used, quality of finishing and curing.

- Impact resistance and long term indentation are normally very good.

Slip resistance

- The slip resistance of surfaces is good when dry but it can be poor when wet, particularly when worn smooth.

- Where enhanced slip resistance is required, an abrasive grit can be incorporated into the finish.

Control of dampness and condensation

These screeds are unaffected by dampness though they may be subject to condensation just as any other solid floor.

Thermal properties – Warmth to touch

Poor

Fire

Non-combustible

Suitability for underfloor heating

Suitable, although it can show excessive drying shrinkage caused by the underfloor heating drying out the material too quickly or by reducing the moisture remaining to a lower value than for an unheated screed.

Sound insulation

Sound absorption is very poor. Sound insulation depends largely on the mass of the structural floor.

Durability

The two factors, which most often lead to the early failure of granolithic concrete, are excessive drying shrinkage combined with poor preparation of the base in bonded construction leading to marked cracking, curling and hollowness. Life expectancy will be at least 50 years for good quality granolithic flooring, though rather less if specification and mixing is of inferior quality. One possible cause of failure due to increased shrinkage is that too rich a mix had been used. Although the shrinkage rate of the finish will always be higher than that of the base, if the difference is too great, poor adhesion will lead to debonding, cracking and curling.

Other factors affecting durability include:

- water: cement ratio in the mix

- proportion of dust in the mix

- adequacy of thickness

- curing

- adequacy of bonding

For other aspects of curing, and for thickness and bonding of screeds see the section on Plastering.

Maintenance

Maintenance is normally limited to removal of ingrained dirt by scrubbing with hot water and a neutral detergent. The surface should not be polished. Repairs to worn or stained patches by epoxy resin bonding agents and skim coats of granolithic is feasible, but such repairs will be visually obtrusive.

Synthetic Resins

Synthetic resins provide flooring materials, which can be modified to achieve a very wide range of performance characteristics, albeit that such versatility and performance can be expensive. These floorings do provide an enhanced resistance to a wide range of chemicals and being jointless offer, a hygienic solution for buildings in specific industries.

The resins used are epoxy resin, polyurethane, polyester and acrylic (methyl methacrylate), often referred to as thermosetting resins. Except where they are used as coatings, they are always mixed with substantial quantities of aggregates, which include sand, quartz, and carborundum. Resin flooring systems allow the integration of a wide variety of materials and objects, and thus add an individual touch to floors. Be it quartz sand in many colours and particle sizes, or granulated polymers, stone and glass, or many types of flat objects: they can all be integrated into the floor coating and produce amazing results. Even a simple combination of colours can create extraordinary effects. There are no limits to shapes and patterns, and almost any shade of colour is possible.

There are three basic types of resin bound aggregate floorings.

- Resin screeds – These are relatively stiff mixes with the material being applied by trowel or sledge followed by power trowelling. The mix proportions are often in the range of 1:5 to 1:9 resin: aggregate. The aggregate size can range up to 5 mm and some decorative screeds have even larger aggregates. Because the resin content is rarely sufficient to fill all the pore space between the aggregate particles, these floorings are often finished with a seal coat of the same resin to provide a hygienic surface. Resin floors with careful selection of resin, hardening system and aggregates can provide excellent chemical and abrasion resistance, and be used for very heavy-duty areas. They are most often laid between 4 and 6 mm thick.

- Self-levelling resin floorings – these are very fluid materials, as their name implies. They contain much finer aggregate and provide very smooth non-porous hygienic surfaces. Often laid in the range 1–3 mm thick, they provide excellent floors in clean rooms, pharmaceutical factories, food processing areas etc. these very smooth floorings can be slippery when wet, a degree of slip resistance can be engineered into some types of resin flooring systems.

- Coatings and seals – many resin screed mixes require a final seal or topcoat, which are discussed in this section even though they could be classed as a coating or seal. Others are discussed in the next section – paints and seals.

Appearance and reflectivity

Base resin and hardener systems tend to vary in colour from clear through to white. Most systems are pigmented, with a wide range of colours being available.

Choice of materials for substrate

Synthetic resin floorings can be laid successfully on a wide variety of primed substrates, but concrete is by far the most common. The alkali content of concretes can inhibit hardening of some resins, and high moisture content can inhibit adhesion, so the longer the concrete is left before applying the flooring the better. Some thermosetting resins require the concrete substrate to be below a certain moisture content before they can be successfully laid.

Strength and stability

Results of testing for compressive strength, flexural strength, bond strength and tensile strength are normally available from the manufactures of resin products, which may give the user some indication of relative performance. However, care has to be taken that the resin product is appropriate to a particular application.

The minimum compressive strength of a concrete base or screed substrate should be between 20 to 25N/mm² but higher strength Grade concrete is commonly required Cement sand screeds usually do not have sufficient strength but fine concrete and polymer screeds are suitable.

Slip resistance

Like most floorings, thermosetting resins are usually safe when dry. Some of the self-levelling types produce very smooth surfaces and can be dangerous when wet, but special grades are available which either contain hard slip resistant aggregates as fillers or have them sprinkled onto the surface before they set to produce fine or rough textures. Many of the products available have excellent slip resistance when wet.

Control of dampness and condensation

- Special formulations of epoxy resins have found widespread use as surface damp proof membranes (DPMs). They adhere well to damp-but-surface-dry concrete at the time of application.

- Resin floors are rarely specified for new construction but are used when a building without a DPM undergoes a change of use (e.g. factory-to-office and basement conversions) or to control excess constructional water in thick concrete bases when insufficient time is available for them to dry.

Thermal properties – “Warmth to touch”

Resin floors provide no thermal insulation and behave similarly to other hard floorings such as concrete and ceramic tiles.

Fire

Resin floorings are unsuitable for use on floors within fire escapes.

Suitability for underfloor heating

Resins are rarely used over underfloor heating although there is no reason why they should not be used, provided the bases are sufficiently strong, crack free and dry and the surface temperatures should not exceed 28 °C.

Sound insulation

Sound absorption is very poor. Sound insulation depends largely on the mass of the structural floor.

Durability

- The resin floor fully bonds with the substrate; therefore, any cracking in the substrate or poor preparation of the surface on which it has been laid will inevitably affect the flooring.

- Epoxy floorings are, in general, not suitable for use in floors where there is a risk of thermal shock, especially where the flooring consists of more than one coat and the coefficient of thermal expansion of the topping is greater than that of the base coat.

- They have excellent resistance to a wide range of chemicals including alkalis and moderately concentrated inorganic acids.

- Epoxies soften at temperatures between 60 and 80 °C and should not be used where liquids above these temperatures can be spilt on the floor.

- Polyurethanes generally have much better resistance to temperature and some can be used where liquids exceed 1000C.

- Most self-levelling thermosetting resins can suffer blistering caused by osmosis.

Paints And Seals

Floor paints are normally used over very large surfaces as a relatively inexpensive means of improving appearance in the short term. Seals are applied to concrete floorings as a means of surface hardening and to prevent dusting, again as a short term measure. Seals are also applied to a number of different synthetic resin flooring systems as discussed above. In many instances the terms floor paint and floor seal are interchangeable.

Paints and seals are normally categorized as one of the following:

- polymer based emulsions e.g. acrylics

- resin based solvent mixes

- oleo-resinous paints

- one and two-pack polyurethanes

- two-pack epoxies

- chlorinated rubber

Polyurethanes are the type most frequently used. Some preparations are available with fine aggregates to enhance slip resistance.

Concrete seals or surface hardening agents are normally found to be one of the following types:

- sodium silicate solutions

- silico-fluoride solutions

- one and two-pack polyurethanes

- epoxies

Solutions of sodium silicate, magnesium or zinc silicofluoride applied to the surface of a good quality concrete floor will often increase its resistance to abrasion and dust formation. This treatment is of little use, though, if the surface is of poor quality.

Appearance and reflectivity

- Paints are available in a wide range of colours. They can discolour under certain conditions of use.

- Seals can significantly affect the appearance of a floor, especially the pigmented types.

- Polyurethanes on timber give a high gloss finish, which becomes matt where trafficked.

Choice of materials for substrate

As is normal with paint systems, the condition of the substrate has a significant effect on performance. Thin coatings cannot be expected to restore the integrity of pitted worn or friable surfaces; indeed, they will readily detach from the high spots. Seals, too, are often expected to work wonders with dusting surfaces, whereas their capabilities are limited by the condition of the substrate. When timber is resealed, it is normally first sanded. Other floorings, such as linoleum, may be also sealed e.g. with acrylics.

Strength and stability

- Two-pack paint mixes usually produce tougher finishes than one-pack. They adhere by adhesion and penetration. Adhesion is affected by the presence of contaminants such as oils or greases on the surface, leading to selective detachment.

- Sodium silicate and silicofluoride seals act by filling the pores of the concrete or screed, coupled with some chemical reaction with the free lime in the cement to harden the surface. They are not used on timber.

- Polymer emulsions are not as good as one-pack polyurethanes, which, in turn, are not as good as two-pack epoxies, and two-pack polyurethanes. The last two give the highest abrasion resistance.

- Because of their small thickness, all paints and seals on floors will have a limited life before wearing through.

Slip resistance

Special textured floor coatings are available which provide varying degrees of slip resistance in wet conditions. Information should be obtained from manufacturers.

Control of damp and condensation

Some polyurethanes and epoxies perform reasonably if laid on dry substrates even if there is no damp proof membrane.

- None can be laid in wet conditions.

- Specially formulated polyurethanes and epoxies can give excellent performance when laid on damp concrete provided it is well prepared and surface-dry when applied.

Thermal properties – Warmth to touch

These surfaces are so thin that they add nothing to the thermal performance of the floor.

Fire

Paints and seals do not materially affect the performance of a screed in fire.

Suitability for underfloor heating

All paints and seals (except bitumens) can be used.

Paints and seals make negligible difference to the floorings to which they are applied.

Durability

- Paint not specifically designed for use on cementitious surfaces will simply not work and unnecessary time and money will be spent removing it later.

- The durability of floor paint systems depends as much on preparation of the surface and degree of traffic as on their formulation. Lack of adequate preparation can lead to patchy wear in a comparatively short time.

- Since these coatings are all very thin, the life expectancy in heavily trafficked areas is always limited. Therefore, in choosing a coating for trafficked areas, the ability to re-coat is vital. Some polyurethanes, for example, do not tolerate a re-coat. Sodium silicate solutions are effective for comparatively short periods and re-treatment is normally needed at regular intervals.

- Some coatings like polyurethanes and epoxies have good resistance to a wide variety of chemicals.

- Polyurethane and epoxy coatings can be affected by osmotic blistering.

Maintenance

It is important that paint systems on existing floors be correctly identified when the time comes for re-coating. It may be necessary to examine samples of old coatings in the laboratory to determine the compatibility of proposed paint formulations. If paint systems are used in industrial locations, hot water or steam cleaning should be limited to polyurethanes.

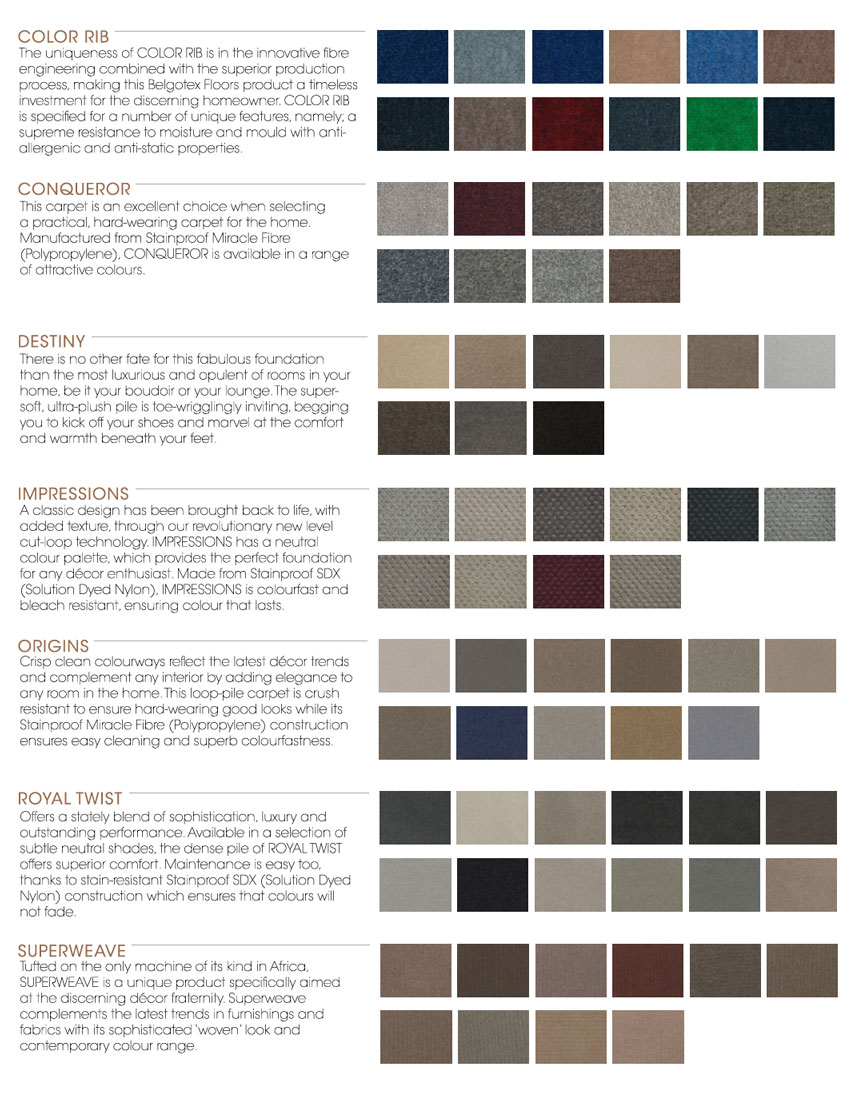

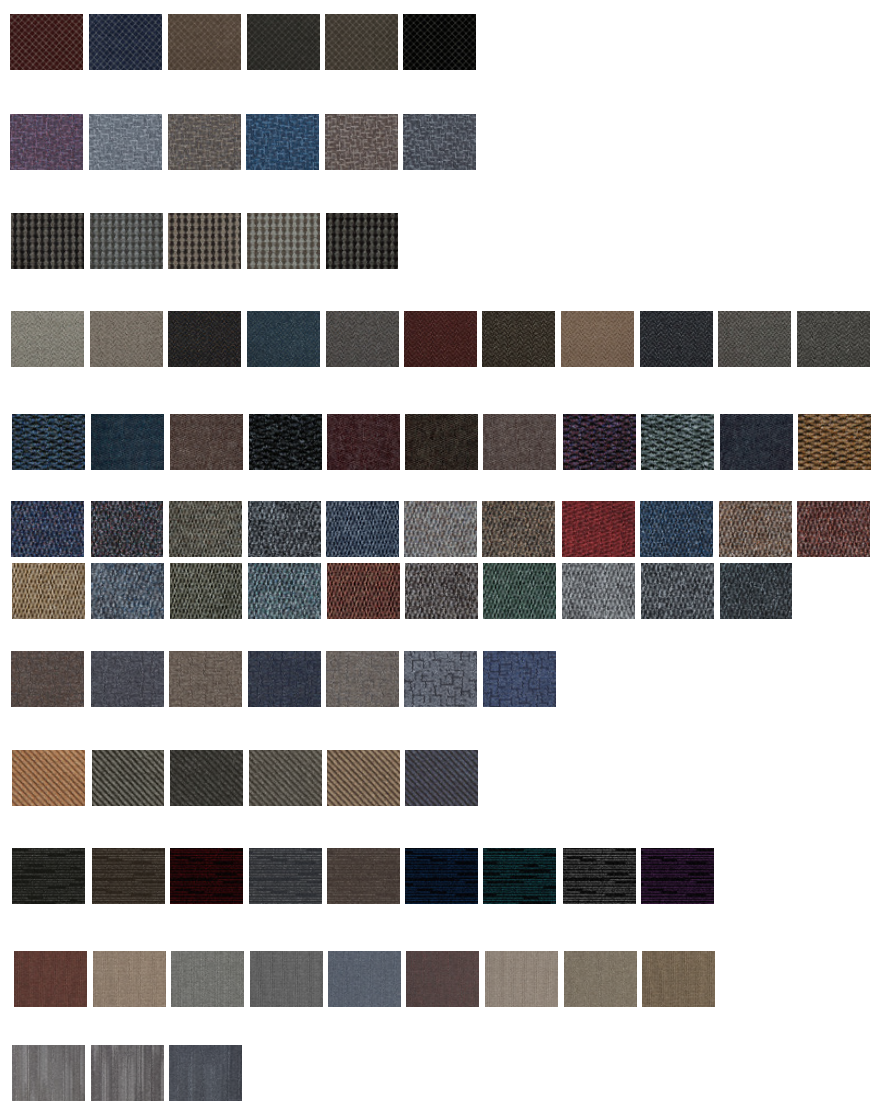

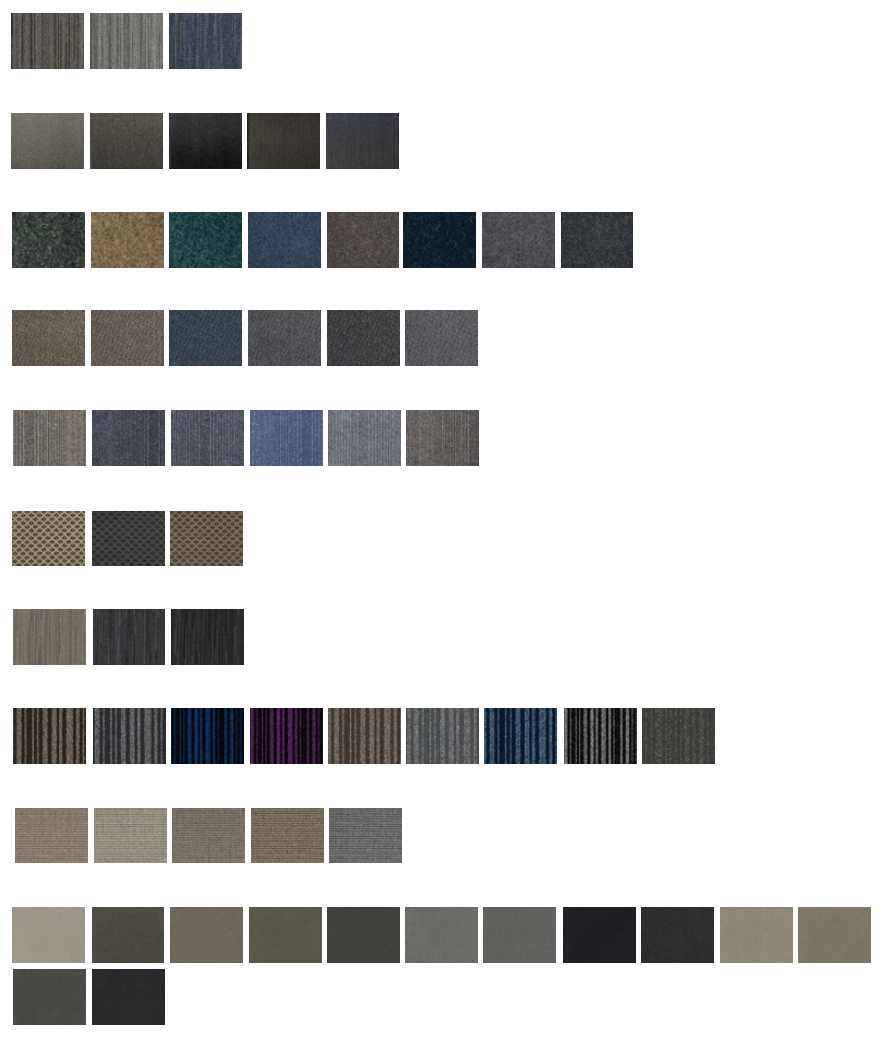

Carpet (Textile)

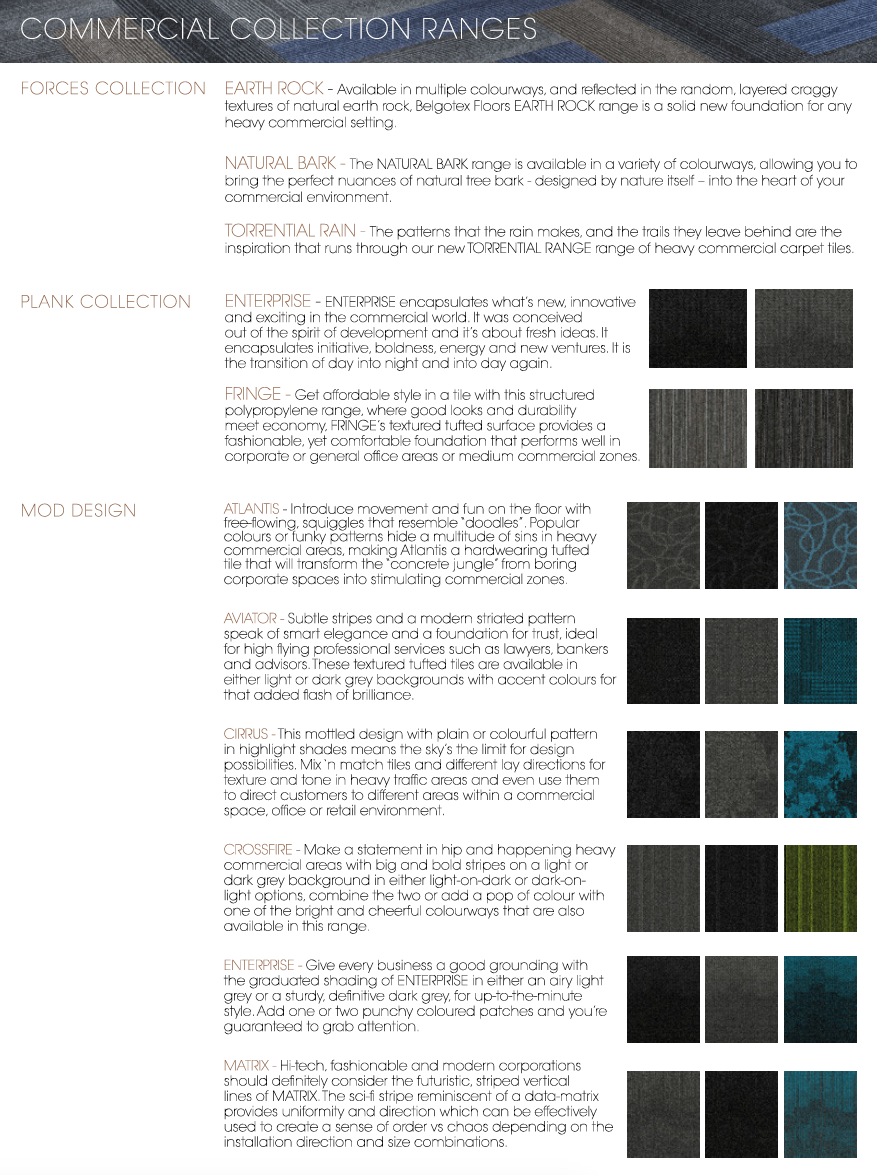

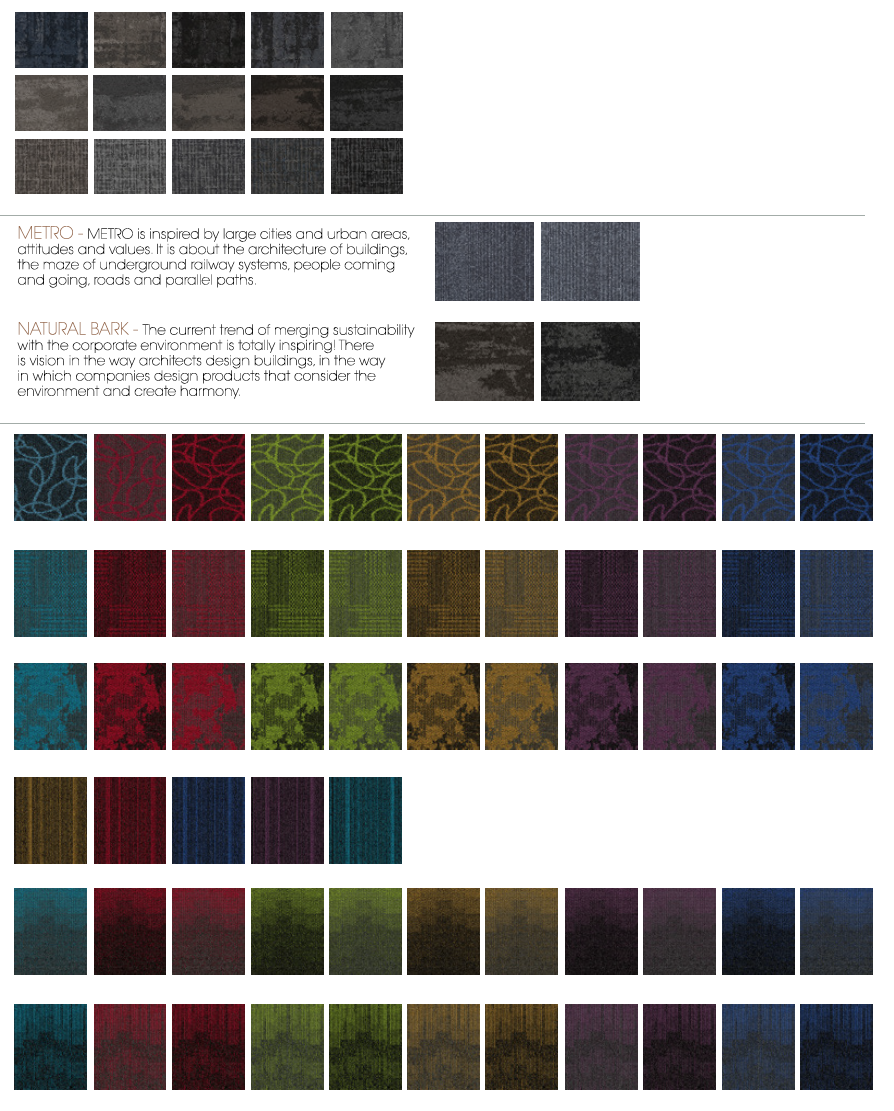

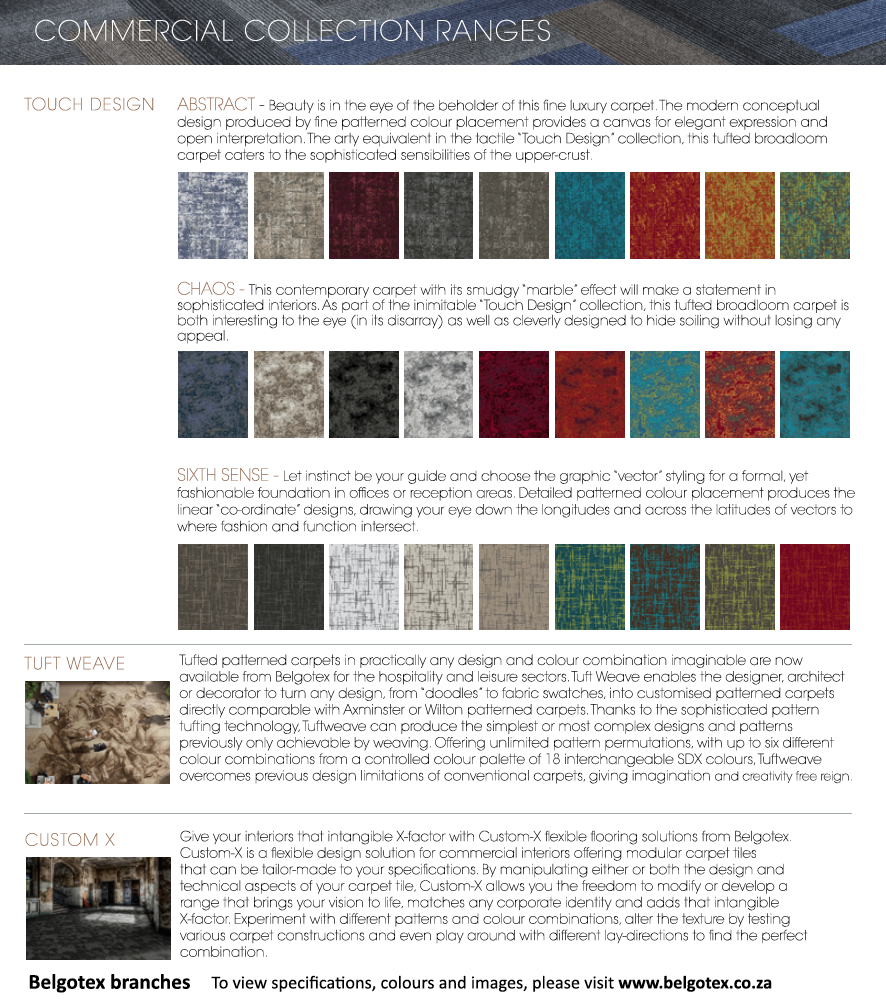

Textile floorings, or more commonly known as carpets, are one of the more commonly used types of floorings in residential buildings, including commercial buildings like offices, albeit these types of applications also make use of carpet tiles. (For more on carpet tiles see notes at end of this sub-section). Materials used in the manufacturing process include wool and cellulose, and various combinations of synthetic fibres such as acrylics, polypropylene and nylon for piles, with polypropylene, nylon and polyesters used for backings. The variety and qualities is enormous; all that can be explained here is to cite a few of the more common varieties together with some of the materials used and some basic carpet terminology including manufacturing processes.

Fibre bonded carpets, often based on polypropylene or nylon, have become popular. They can offer considerable advantages from the point of view of ease of cleaning, and give excellent abrasion resistance.

The main manufacturing processes for carpets are:

- Woven – the carpet is produced on a loom similar to woven cloth and is a cut pile. Usually many different coloured threads are used and this process allows one to produce complex patterns from predetermined designs. These carpets are usually the more expensive.

- Tufted – the carpet is produced on a tufting machine using a single coloured or sometimes non-coloured thread. If non-coloured thread is used, the carpet will be dyed or printed with a design as a separate process. Modern tufting technology now enables the production of basic geometric patterns. Tufted carpets can be either cut pile, loop pile or a combination of both. Tufted carpets are cheaper than woven carpets.

- Needlepunch – these carpets are more technologically advanced and growing in popularity due to their durability and stain-resistant properties. Needlepunch carpets are produced by electrostatic attraction of individual synthetic fibres together with a series of barbed needles. All the fibres are anchored into a resin backing, giving superb stability with extremely high durability.

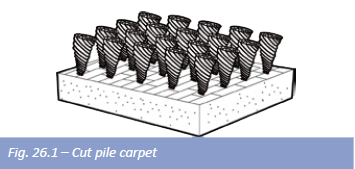

Cut Pile

The carpet yarn loops have been cut off to create individual yarn ends for a soft, luxurious look and feel. Best suited to those special areas where underfoot comfort is important.

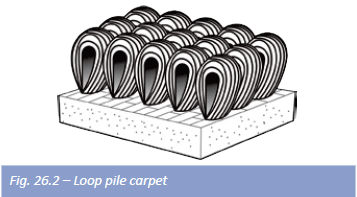

A more durable carpet, the carpet fibre loops are not cut or sheared, so the loops form the carpet surface. Soil tends to stay on the surface, making cleaning easier. Level loop pile has a tight, pebbly surface. Multi-level loops produce interesting patterns that have enhanced soil-hiding capabilities. Textured loops are constructed with loops of slightly different heights, randomly placed.

Carpets are manufactured from either natural or synthetic fibres, or a blend of any, the most common types include:

- Wool or Wool blended with synthetic fibres – 100% Wool has excellent durability and is the only carpet product with a fire rating of one. Blended Wool yarns are used a lot in modern carpet production.

- Nylon – This product is the most popular synthetic fibre used in carpet production. Nylon can be dyed topically or dyed in a molten state otherwise known as solution dying. Nylon can be printed easily and has excellent wear characteristics. In carpets, nylon tends to stain easily because it possesses dye sites on the fibre. These dye sites need to be filled in order to give nylon any type of stain resistance.

- Polypropylene – This polymer is used to produce carpet threads mainly because of its cheaper price, Polypropylene is difficult to dye and does not wear as well as wool or nylon. Carpets made from this fibre are usually only suited for light to medium domestic use.

Carpet grading

Carpets are graded in accordance with the following SANS use classes; classes 1 and 2 are seldom specified, with class 3 being the most commonly specified carpeting for residential applications. (Textile floorings are tested and graded for their suitability to specific areas)

Class 1 – Light Residential

Class 2 – Medium residential

Class 3 – Heavy Residential/ Light Commercial

- Areas where high-energy absorption is desirable

- Domestic rooms

- Corridors subject to heavy traffic

- Playrooms

- TV rooms

- Offices subject to light traffic

Class 4 – Medium Commercial

- Areas subject to heavy traffic and wheel traffic

- Offices

- Shops

- Hotel bars

- Public lounges

- Areas subject to very heavy traffic and wheel traffic; areas where

- castor chairs are used

- Public buildings

- Hotel and shop entrances

- Hospital corridors

- Lift areas

Carpet backing

Carpet backing plays a vital role in maintaining the life and appearance of a carpet. Traditional jute (hessian) weft backings are complicated to install, will rot when wet and require more maintenance. A number of backing systems using new generation synthetic fibres are available, from woven polypropylene with exceptionally hardwearing and durable properties to more cost effective resin backings typically used with Needlepunch products.

Note: Most carpets are usually laid with an underlay/ underfelt or incorporate an underlay or backing material in their construction.

Underfelt

Underfelt can be described as a felt of textile/fibre, or foam plastic, or rubber, put down before the carpet is fitted. Underfelt should weigh at least 1000g/m² in accordance with SANS 1419:1997 to prevent collapse and should not act as a vapour barrier or cause dampness.

Fitting

Carpets are normally fixed by gripper battens round the perimeter of the area to be covered; or they can be stuck using an appropriate adhesive, which may give problems when they need to be replaced.

Static electricity

- Certain kinds of textile flooring, particularly those containing synthetic fibres, in common with certain kinds of vinyl and other plastics, have been prone to problems caused by the buildup of static electricity from friction. The phenomenon occurs in conditions of low humidity, and can be uncomfortable to occupants and disastrous to microelectronics or in atmospheres where flammable gases accumulate.

- This is mainly a problem with new carpets and is particularly evident during the first heating season. As the carpet becomes more soiled, conductivity improves and static is therefore less of a problem. The problem can be ameliorated by incorporating conducting materials within the flooring.

Thermal properties – “Warmth to touch”

Very Good

Fire

Although there is normally no requirement for fire protection of textile floor coverings in most situations in buildings, products are tested and classed with SANS fire ratings.

Suitability for underfloor heating

Good – textiles will have an insulating effect on the flooring substrate, and the effects of heating should always be considered.

Sound insulation

Sound absorption is usually very good; sound insulation depends largely on the mass of the structural floor.

Durability

- Life expectancy will be about 10 years for natural fibres and substantially longer for synthetic fibres, depending on traffic conditions.

- The backing or underlay has an important influence on the overall life of a product.

- Most carpet manufacturers guarantee and provide warranties on their products for between five to ten years (subject to terms and conditions).

- A number of manufacturers supply carpets with fibres that are stain proof, extending the life of the carpet.

Maintenance

- All carpets require maintenance to optimize wear life, performance and appearance retention. A carefully planned and executed maintenance programme will help to preserve the aesthetic and functional benefits of textile floor-coverings, and will maximize the return on this expensive investment. Regular maintenance costs will pay for itself by extending the carpets working life and deferring replacement costs. This programme should be considered at the time of carpet selection and must be implemented immediately after installation.

- Regular vacuuming is the most important component of carpet maintenance. It is the primary means of removing dry soiling, the basis of effective soiling control. Loose particles account for up to 80% of the total soil in a carpet, and become harder to remove the further they are pushed into the pile.

- Walk-off mats should be placed at all entrances to carpeted areas to serve as soil barriers.

Carpet tiles

- Carpet tiles are manufactured in the same way as carpet sheeting and share the same properties. The only real difference being, they are available in lesser variety than that of sheeting (Broadloom).

- Carpet tiles may be replaced easily and inexpensively when worn or soiled. Alternatively, they may be rotated to allow even wear resulting in a consistently uniform appearance.

- Carpet tiles can be applied in imaginative configurations using different colours and patterns or to create attractive border features

- General method of installation would be a tessellated configuration. Successful monolithic installations are dependent on good screeds, precise laying and tile quality.

- It is imperative that a carpet tile not only maintains its aesthetic appearance over time, but that it has the ability to maintain its shape and to remain flat on the floor surface without doming or buckling. To do this, it should possess five fundamental characteristics for optimal in-situ performance:

- Dimensional stability

- . Balance between flexibility and rigidity

- . Sufficient weight and mass

- Strength of construction

- Resistance to fire

Linoleum

Linoleum or as some refer to as ‘Lino’ is a floor covering made from a mixture of linseed oil, resins, cork and wood flour, traditionally adhering to a hessian backing, though other materials have been used as backings in more recent years. Heat treatment then follows to create a tough material, which is consistent throughout its structure and has a smooth surface.

Linoleum is available in sheet and tile form in a range of thicknesses from 2, 2.5 and 3.2 mm though other thicknesses may be available to special order. Linoleum sheeting can be laid with butt joints or grooved joints; where the grooved joints are hot welded with a fully flexible coloured welding rod to provide a homogeneous hygienic sealed finish.

Normally abutments are covered with skirtings or a cover mould. The thinner products can be formed as coves by using formers to which the linoleum is stuck. Linoleum is vulnerable to scuffing in areas of heavy traffic such as at thresholds; some protection, perhaps in the shape of a timber moulding or aluminium extrusion, may be needed.

Adhesives used for sticking down linoleum have been of many varieties: vegetable and casein glues, lignin pastes, gum spirit adhesives, latex cements, bitumen rubber, and tar emulsions and bitumen rubber solutions in petroleum solvents. Not all these materials would now conform to health and safety legislation, or indeed be available. The adhesives most often used are resin alcohol and gum spirit.

Appearance and reflectivity

Linoleum comes in a wide range of colours and is soft, resilient, and easy to maintain, but can suffer from indentation.

Choice of materials for substrate

Linoleum floorings have been laid successfully on a wide variety of substrates. Although the material is flexible, it performs best on a firm base i.e. a concrete sub-floor.

- All subfloors must be tested for moisture content, with a hygrometer reading showing a moisture content of less than 70% prior to installation,

- Where timber floors are used as the sub-floor, they need to be in good condition, with no warping and with nail heads punched below the surface.

- Uneven solid or suspended timber sub-floors may need preparation to meet the required standard.

Strength and stability

- Standard linoleum may not be suitable for use in situations where there is a risk of impact loads from sharp objects and wheeled traffic.

- A toughened form is available, in which the surface is reinforced giving improved resistance to point loads.

Wear resistance

Good.

- Good, although wax polishes should not be allowed to build up

- since surfaces can then become slippery.

- Linoleum can be slippery when damp.

- Control of dampness and condensation

- An effective damp proof membrane under ground bearing floors/slabs must be installed where Linoleum floorings are used.

- Linoleum is susceptible to degradation in the presence of water

- rising from below, or where spilt in quantity and remaining on the surface.

- All subfloors must be tested for moisture content, with a hygrometer reading showing a moisture content of less than 70% prior to installation.

Thermal properties – Warmth to touch

Good.

Fire

- Combustible, though this is normally of little consequence unless used in escape routes in buildings where a fire certificate is required.

- Although the material can be marked by cigarette burns, normally any scorching can be removed with care using a fine abrasive.

Suitability for underfloor heating

Suitable provided that the surface of the subfloor does not exceed 27°C (a small insulating effect will occur if cork has been used as one of the raw materials in the manufacturing process).

Sound insulation

Sound absorption is usually very good. Airborne sound insulation depends largely on the mass of the structural floor.

Durability

Life expectancy will be around 15–25 years depending on traffic. The most common cause of lifting is construction moisture in the substrate, it is therefore important to ensure the sub-floor is sufficiently dry before installation (see Control of Dampness and Condensation above).

Maintenance

- Infrequent washing with a wet mop and a mild detergent is the preferred method of maintenance.

- Scrubbing or abrasive cleaners, and particularly highly alkaline cleaners, must be avoided.

- Thin layers of either solvent or emulsion wax polishes (dry-sheens and buffables) are beneficial but should not be allowed to build up.

- Oil based seals will discolour linoleum.

Note: Linoleum sheet and tiles must be allowed to relax for 24 hours in a uniform room temperature between 18°C and 27°C prior to installation. It is essential that during the course of installation the material be rolled in both directions with an articulated 68kg three sectional metal floor roller.

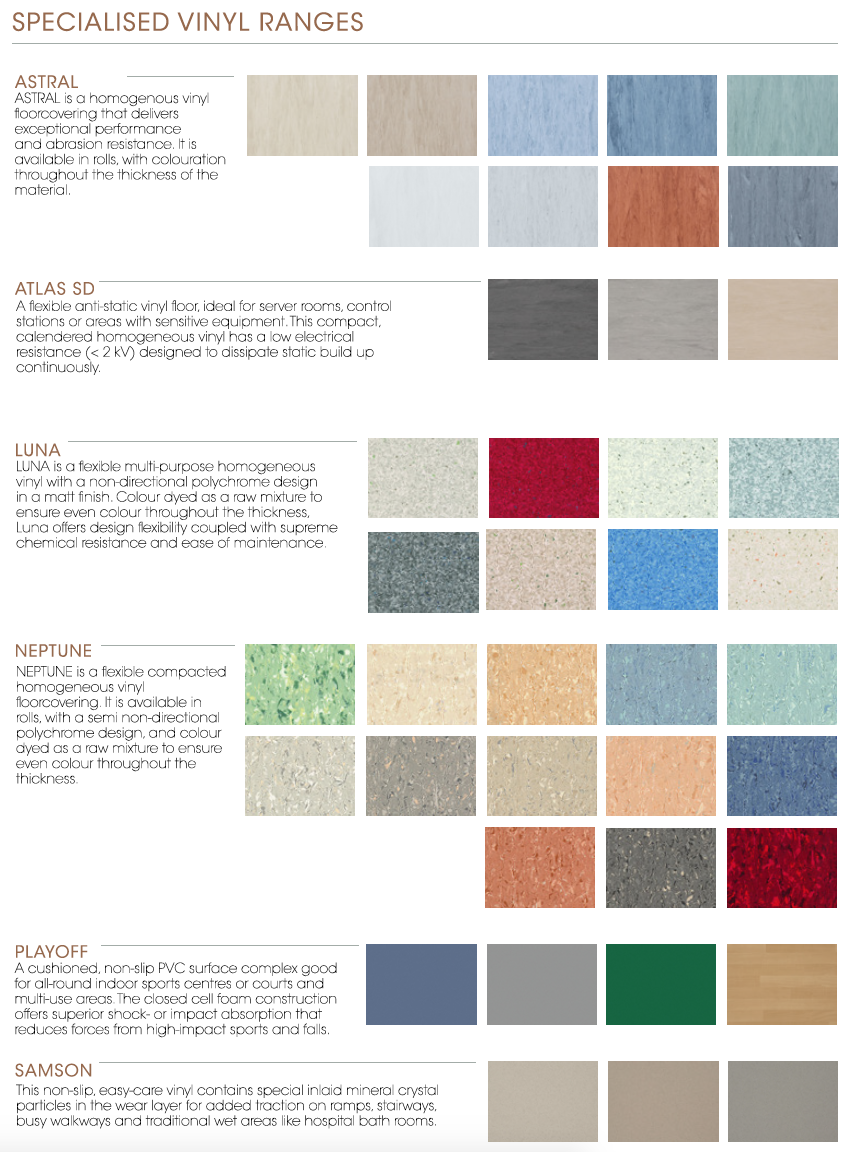

Vinyl (PVC Flexible/Semi-Flexible)

The development of flexible PVC flooring – frequently referred to as vinyl – has been one of rapid growth since the 1960s. There are vinyl-flooring options for every budget, every décor and every taste. Vinyl is a low-maintenance, high performance flooring option to just about any well-trodden area. Some grades can be used in heavy wear situations and products for many different uses including Healthcare, Electro Static Discharge protection and Safety Flooring, Acoustic Foam flooring for comfort and sound absorption are produced.

Ranges come in a multitude of colours in both directional and non-directional, including luxury vinyl tile products in wood, stone and other natural finish effects.

The tiles and sheets consist of PVC resins, plasticisers, stabilisers and extenders, forming a rubber-like material, which varies in consistency between hard and soft. PVC cannot carry large quantities of fillers without losing its rubber-like properties. The material is calendered to thicknesses varying from 1–3 mm, formed into multilayer sheets as appropriate and left as sheets or cut to size as tiles. Typically, unbacked flexible PVC is available in roll or tile form and backed material usually in roll form only.

Flexible PVC can be laid with butt joints, or it can be hot air welded to form a virtually continuous surface; with some materials, joints can be solvent welded.

Appearance and reflectivity

Since most of the basic materials are light in colour, a wide variety of clean bright colours and marbled effects is available. Seams can be welded, giving an almost unbroken surface. Welding rods can be found in colours that will provide contrasting effects to tiles and sheets or colours can be mixed and matched to suit your requirements.

Choice of materials for substrate

- PVC flooring can be laid on a wide variety of substrates. The most common substrate will be a screed or concrete. Although this type of flooring is flexible, it will be susceptible to movements at cracks and joints in the base leading to rippling

- Subfloors must be smooth, hard, clean and dry before laying commences.

- All subfloors must be tested for moisture content, with a hygrometer reading showing a moisture content of less than 70% prior to installation.

- Timber boarded floors will not usually cause flexible PVC flooring to crack, though any warping will show and movements in the timber may result in rippling

- Existing floors of ceramic tiles may provide a suitable base if a levelling screed or latex underlayment is applied.

Strength and stability

The resistance of unbacked PVC flooring to indentation is good, though the material is soft. The backed type, though, can be cut by furniture feet.

Wear resistance

Normally the wear resistance of these materials is between good and excellent.

Slip resistance

- Very good in dry situations

- Smoother types can be very slippery when wet.

- Special slip resistant grades are available

- An effective damp proof membrane under ground bearing floors/slabs must be installed where PVC – vinyl floorings are used.

- All subfloors must be tested for moisture content, with a hygrometer reading showing a moisture content of less than 70% prior to installation

Thermal properties – “Warmth to touch”

The material itself is not warm to touch. However, the backed materials can show an improvement, depending on the insulation value of the backing e.g. Novilon

Fire

- Combustible

- All types of PVC flooring are very vulnerable to cigarette burns

Suitability for underfloor heating

Suitable provided that the surface of the subfloor does not exceed 27°C

Sound insulation

Felt backed vinyl products will give a degree of protection against impact sound.

Durability

Life expectancy can be 15 to 30 years for a good quality vinyl.

(PVC) flooring

- PVC does not age as rubber does and should retain much of its resilience.

- If PVC materials are not well adhered to the substrate, though, they can stretch under traffic and bubbles can form which will become torn in use.

Maintenance

- PVC is relatively easy to clean using only water and neutral detergents, so making it possible to maintain a satisfactory appearance. Nevertheless, some types of cleaning agents can give problems, mainly shrinkage. This has been attributed mainly to the effects of stress relaxation in sheets or tiles, or to the migration of plasticisers into certain adhesives.

- Highly alkaline cleaners should not be used as they can react with plasticisers.

- Only water emulsion polish complying with SANS 1042 and detergents complying with SANS 825 should be used to effectively maintain the flooring materials.

- Poor maintenance or the use of the wrong cleaning materials will not only result in an unsightly floor, but may irreparably damage the flooring.

Note: Vinyl sheet and tiles must be allowed to relax for 24 hours in a uniform room temperature between 18°C and 27°C prior to installation. It is essential that during the course of installation the material be rolled in both directions with an articulated 68kg three sectional metal floor roller.

Rubber

Rubber flooring is available in sheet or tile form, in varying degrees of hardness, and with various forms of surface profiles to enhance slip resistance.

Appearance and reflectivity

- Sheet and tile rubber flooring is available in a wide range of plain or marbled colours.

Choice of materials for substrate

- Rubber flooring can normally be stuck to a flat screed using a contact adhesive or other recommended proprietary adhesives.

- Uneven solid or suspended timber subfloors may need preparation to meet the required standard.

- Where rubber flooring is to be stuck to ground bearing concrete floors/slabs with adhesive, a damp proof membrane must be incorporated into the subfloor.

- All subfloors must be tested for moisture content prior to installation.

Strength and stability

The resilience of rubber flooring can be exploited for a variety of applications e.g. indoor sports.

Wear resistance

Very good

Slip resistance

Rubber flooring is unsuitable for areas around cooking, washing or laundering, or in spaces near entrance doors. It is very poor when smooth and wet unless ribbed or studded.

Control of dampness and condensation

- Although rubber as a material is largely unaffected by dampness, the same cannot be said of adhesives used to stick it to screeds or other substrates. Where rubber flooring is to be stuck to ground bearing concrete floors/ slabs with adhesive, a damp proof membrane must be incorporated into the subfloor.

Fair – Rubber flooring is too thin to add substantially to the thermal characteristics of the substrate.

Fire

Rubber flooring offers outstanding fire resistant properties with low flame spread and low smoke emission. Surface shows no burns and is resistant to cigarette burns.

Suitability for underfloor heating

Suitable provided that the surface of the subfloor does not exceed 27°C, provided the adhesive is unaffected.

Sound insulation

Sound absorption is usually very good. Airborne sound insulation depends largely on the mass of the structural floor. Rubber flooring can also be stuck directly to a non-floating floor.

Durability

The lifespan of natural rubbers normally exceed 10 years after which they oxidize and become brittle. Failure will occur much earlier, though, if the substrate is wet.

Maintenance

Solvent-based polishes can cause softening of the rubber, which, in turn, leads to stretching and detachment from the substrate. Since each installation is subject to different usage situations, adaptation of recommendations for local conditions may be necessary. Any maintenance products used should be selected and handled with consideration of the manufacturers’ recommendations.

Jointed Hard Finishes

Tiles; ceramic, natural stone, terrazzo, concrete flagstones and brick pavers.

The floorings dealt with in this section tend to be both hard and durable. The materials include Ceramic tiles, brick pavers, concrete flagstones, natural stone tiles, and terrazzo tiles. The materials described are fundamentally broken down into two specific categories:

- Tiles

- Paving

These two categories are dealt with in separate sections in this publication. However, in order to allow the reader to draw a comparison of these types of materials being used as a flooring surface versus others described in this section, we have covered the basic performance requirements and properties of tiles and paving as one in this sub-section.

The enormous variety in products as described above, in addition, the different types of manufacturing processes make it impossible to cover every type of product manufactured; all that can be done here is to try and provide sufficient information as a guide to facilitate the reader making an informed decision or choice.

Note: For more information please see section on tiling.

Appearance and reflectivity

- Tiles are available in a variety of types, sizes and colours.

- Most manufacturers produce a range of special size tiles to fit awkward spaces, and to form coves, upstands and stair treads.

- When tiles are subject to wide dimensional deviations in manufacture, it should be remembered that the wider the joint, the less apparent will be these variations in size when the floor is laid.

- Clay Pavers are normally available in standard brick size, but with a reduced thickness of 50 mm, with concrete pavers available in many different sizes, shapes and thicknesses; pavers also include special bricks to suit specific functions e.g. a bull nose paver for a pool coping. For more details see: Paving – Materials

- Light shades give reflectances of around 0.45, medium shades around 0.25, and dark shades around 0.10. Remembering many of these products are used externally where high reflectances are not ideal, especially when using a light shade ceramic tile e.g. light grey; which give a terrible glare in direct sun.

Substrates and beddings

- Tiles are normally laid on concrete bases or screeds. If they are laid on timber bases, great care will be needed to accommodate their brittle characteristics.

- Brick pavers and flagstones can be found laid on sand or river-sand beds, or even upon consolidated earth, including concrete bases

Strength and stability

- Thin tiles will be less able to resist impact damage unless they are fully bonded.

- In specifying thin tiles, a balance has to be struck between initial cost and impact resistance. The thinner tiles may cost less but are more vulnerable to impact damage than thicker tiles.

- Loosening or debonding of tiles from the substrate is not necessarily the result of bad workmanship. It could be due to drying shrinkage or moisture expansion of the tiles.

- Brick pavers are used where impacts are expected to be severe. Pavers thicker than the normal 50 mm are available, and, if necessary, improved impact resistance can be obtained by laying the pavers on edge; for further information see: Paving – Materials

- The necessary thickness of screeds to receive different types of floorings, including tiles has been dealt with in the plastering section in this publication; for further information see: Plastering – screeds and toppings

Wear resistance

- Abrasion resistance of these products is good to very good, especially for the harder vitrified or semi-vitrified products fired at high temperatures.

- Impact resistance is normally fair to excellent.

- Resistance to long-term indentation is excellent.

- Where pavers, flagstones and tiles are laid herringbone (pattern at 45°) across the main lines of traffic, they can offer improved resistance to wear from wheeled traffic. This is because impacts on protruding edges are glancing rather than direct.

- Ceramic tiles are normally tested for surface hardness by a MOHS test;

for further information see: Tiling – Terminology

- Paving bricks slip resistance is usually very good. However, when oil has been spilt on the surface of paving bricks, with the addition of water they can be slippery.

- Depending on their characteristics, the slip resistance of the surfaces of smooth tiles is fair to good in dry conditions, except when polished or waxed. They can be slippery when wet, especially the polished stone types e.g. granite. They can be particularly slippery when both polished or waxed and wet. For this reason, textured or unsealed porous tiles are specified for the surrounds to swimming pools and other exposed external applications.

- Ripple finish type tiles are slip resistant, even when wet.

- Slip resistant nosings are necessary on external tile stairs.

Control of dampness and condensation

- Tiles and paving bricks are almost totally unaffected by moisture from above or below. However, the property of water absorption gives a good indication of other properties of tiles and bricks such as durability.

- Most hard type floorings will sweat (condensation) in unheated buildings under certain weather conditions and therefore may become slippery.

- Most tiles have a life expectancy of about 50–65 years – with brick pavers having about the same – depending naturally on the severity of service conditions. Nonvitrified fired clay tiles may have shorter lives.

- Flagstones should be well cured and allowed to dry partially before fixing in order to limit drying shrinkage.

- To a large degree, durability depends on the adequacy of the bedding and the completeness of filling the joints, which if not done effectively will lead to spalling¹ of some tile products especially natural stones like marble or travertine. (The amount of movement required to cause spalling in a brittle material is not very great). Spalling – the crushing of an edge or corner of masonry or tile or precast concrete, or the general flaking of a surface.

- Modern ceramic tiles are relatively easy to clean and can provide very hygienic surfaces.

- Brick pavers are not so easy to clean, depending on the surface textures.

- A floor of brick pavers is straightforward to repair, provided matching pavers are obtainable.

- Concrete flagstone surfaces are difficult to maintain in anything resembling their original appearance since even the densest concrete will absorb liquids and become stained. Scrubbing with hot water and detergents will remove dirt. The surface may be sealed with a hardening agent or a resin from time to time to prevent or reduce staining and dusting (see paints and seals).

- Cleaning should be with neutral detergents only. Most stones and marbles can be stained by oils and greases, which will be difficult to remove.

Thermal properties – “Warmth to touch”

Cold

Fire

Non-combustible

Suitability for underfloor heating

Very suitable.

Sound insulation

Sound absorption is poor.

Durability

Maintenance

Timber & Timber Products

Characteristic details

The species of timbers suitable for flooring are too numerous to mention in detail in this publication, with this vast variety available, each floor can be individualized according to specific needs or tastes, with each wood species having its own qualities in terms of hardness, grain and colour. With genuine wood, each plank has its own unique grain. In addition, some species lend themselves to staining, while others are most beautiful in their natural tone. Timber can be categorized in two botanical groups:

- Hardwoods are the species, which belong to the botanical group angiosperms, and can be described as wood from broad-leaved, usually deciduous trees. Hardwoods are often used in decorative applications, but are not always hard.

- Softwoods are the species, which belong to the botanical group gymnosperms. Softwoods often contain resin, which makes them waterproof. Softwoods generally have less moisture than hardwoods, are easier to work, usually less decorative and used for utility, not appearance. Small firm knots are normally acceptable in softwoods intended for use as the final flooring, but are not acceptable in hardwoods. Heartwood is the wood that has finished growing, usually the best timber in a log, darker and more durable than sapwood. Sapwood is the outer woodof a tree, which before felling was living tissue and is softer and paler in colour than the heartwood although not always weaker than the heartwood.

Allowing for movement

Wood and wood based panel products are subjected to dimensional movement as moisture content changes, and provision must be made for this movement to take place without disrupting the flooring. Movement is normally accommodated at the perimeters of rooms where skirtings cover the edges. Vulnerable areas are at door thresholds and staircase landings.

It is the relative atmospheric humidity (RH) that is in principle completely decisive for the appearance and movements of the wooden floor and, in the long run, also its function. A wooden floor, which is subjected to very low or very high atmospheric humidities, will shrink and swell beyond the limits indicated by the manufacturers. It is important to understand that these limits are set not only from an aesthetic viewpoint.

Appearance and reflectivity

- The species of timber is often selected for its appearance, provided durability can be predicted.

- There are too many species for meaningful comment on appearance.

- The quality of the wood is crucial to the appearance of the finished floor, though, as a natural material, it is inevitable that there will be differences in grain and colour between units. Indeed, it can be argued that it is this variability, which gives a wooden floor much of its character.

- In general, some of the paler coloured woods, such as maple, tend to bleach slightly on exposure to sunlight. They may yellow too. Other woods, such as iroko and afrormosia, tend to darken.

- Sapwoods and heartwoods tend to change colour at different rates.

- It should be remembered that re-sanding old wood floorings would often reveal a quite different colour from that to which owners have become accustomed.

Choice of materials for substrate

Timber flooring can be laid on a wide variety of substrates. The most common substrate will be a screed or concrete base where boards are laid normally to form the deck, whereas strip flooring is laid normally on battens on a concrete or dense screeded base. Where the substrate is solid, it must be level and dry, and an effective damp proof membrane is essential.

Wear resistance

- Wear resistance depends on the species and structure of the timber. Although surface finishes, especially those based on polyurethanes, can slow down the rate of wear of a timber surface, they have only a marginal effect on hardwoods.

- Abrasion resistance is fair to very good for unprotected hardwoods and poor to fair for unprotected softwoods.

- impact resistance is fair to very good for hardwoods and poor to fair for softwoods.

- Long-term indentation is fair to very good for hardwoods and fair for softwoods.

- Modern layered floorings have a lacquered finish, which protects the wood, and allows the natural beauty of the wood grain to be revealed and provides a strong, durable surface that will last for years.

- Most laminate floors are manufactured with a highly abrasion-resistant overlay, providing a durable surface, which will last for years (also see utilization class under laminate floors).

- Slip resistance of timber surfaces is very good for both hardwood and softwood boards, blocks and strip when dry.

- It can be very poor if the surface is wax polished.

- When timber floorings or products are used on stairs, a slip resistant nosing is recommended on stair treads.

Control of dampness and condensation

- An effective damp proof membrane under ground bearing floors/slabs must be installed where timber floorings are used.

- Where there is a void beneath a timber floor it should be ventilated to the outside air.

Thermal properties – “Warmth to touch”

Most timbers are fairly warm to touch.

Fire

Timber is combustible

Suitability for underfloor heating

- Timber and timber based floorings are not the best of materials for use over underfloor heating owing to their thermal insulating properties and their propensity to dry out and shrink (unless moisture contents can be well controlled) when heating is on; also their ability to pick up moisture and expand when heating is off. If underfloor heating is going to be used it is recommended that one discusses this with the supplier or manufacturer of the flooring.

Sound insulation

- Wood floating floors consisting of timber boards over battens laid over a resilient sheet on a concrete or timber subfloor will give good impact sound insulation.

- The performance of airborne sound insulation depends on overall thickness and mass of the floor and the number of joints.

- Panel products, with fewer joints per unit area, give slightly better performance than strip or board flooring.

- Structural floors of wood, surfaced with boards or panel products, usually give rise to noise when trafficked.

- Walking comfort and the sound a floor makes when we walk on it is important in the way we perceive and enjoy it. A number of manufacturers of laminate floors have products available with built-in Sound Insulation, which will both reduce sound and improve walking comfort.

- Softwoods, which have not been surface, protected, when subjected to traffic, will rapidly deteriorate.

- Softwoods treated with polyurethane seals will improve their durability.

- Hardwoods are more durable, though they still need sealing or ‘feeding’ to keep them in good condition.

- Layered wooden flooring or engineered wood or also known.

- as multi layer flooring which have a factory-applied acrylic finish or lacquer applied to the planks will resist most common household stains for up to 24 hours.

- Dirt and sand have the same effect as sandpaper on wooden floors, especially laminate floors. Anti-soiling protection or mats should therefore be provided close to entrances and in areas where dirt and moisture might be brought indoors.

- Using water to clean wood floorings should be kept to an absolute minimum, even if the flooring has been sealed.

- Caustic cleaning agents should not be used on wooden floorings.

- Periodical stripping of old emulsion waxes will be necessary, and it may be necessary to use a mildly alkaline detergent. If waxes used have been of the solvent type, then stripping should be unnecessary.

- The thicker timber floorings are often re-sanded before resealing.

Durability

Maintenance

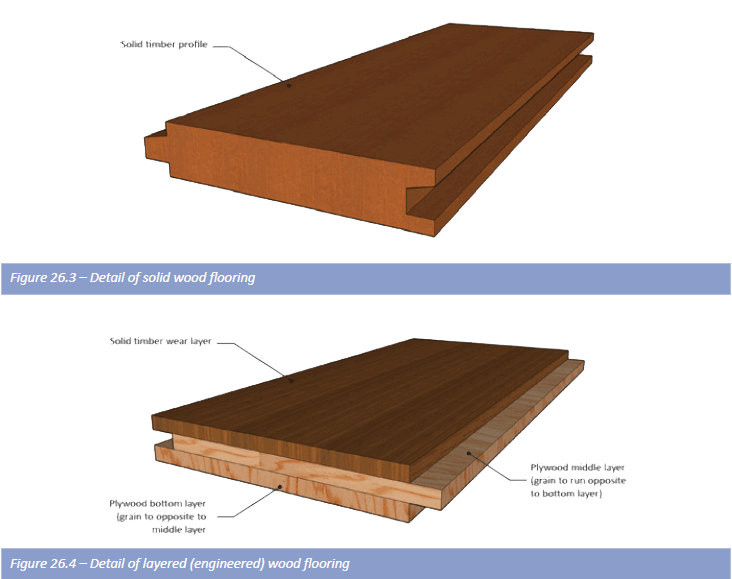

Solid Wood Flooring

Internationally, hardwood floors have become the number one choice floor covering in upmarket homes. Figures show that by installing solid wood floors when renovating or building a home, owners can expect to appreciate at least 10% on their investment in the home’s resale value. This is one of the reasons why the prestigious genuine wood flooring market has tripled in less than a decade. In South Africa, the growth is even more dramatic.

Increasingly perceptive South African consumers and their design professionals – better informed and more internationally aware than ever before – are now also discovering the many benefits of hardwood flooring. That said, when considering hardwood floors keep in mind that they may not work well in areas where they regularly come into contact with water, such as in bathrooms. Also consider where they are going. Light floors reflect light and make rooms appear bigger. Big rooms may look better with dark floors that create a cosy atmosphere.

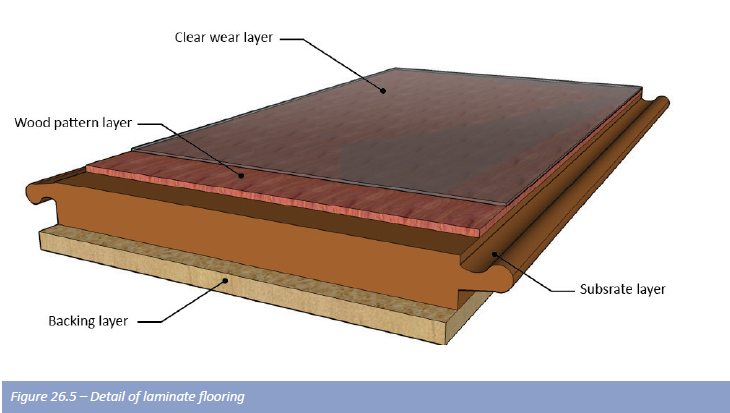

Layered Wooden Flooring (Engineered)

The construction of layered wooden flooring is made up as follows; the wear layer or top layer on each plank is a selected hardwood veneer. The middle layer consists of a high-density material, using a high-density fibreboard or plywood. The bottom layer is made of pine, other softwoods or plywood, which allows the construction to perform flawlessly in a variety of climates and environments. The flooring is usually finished with a factory pre-finished acrylic coating.

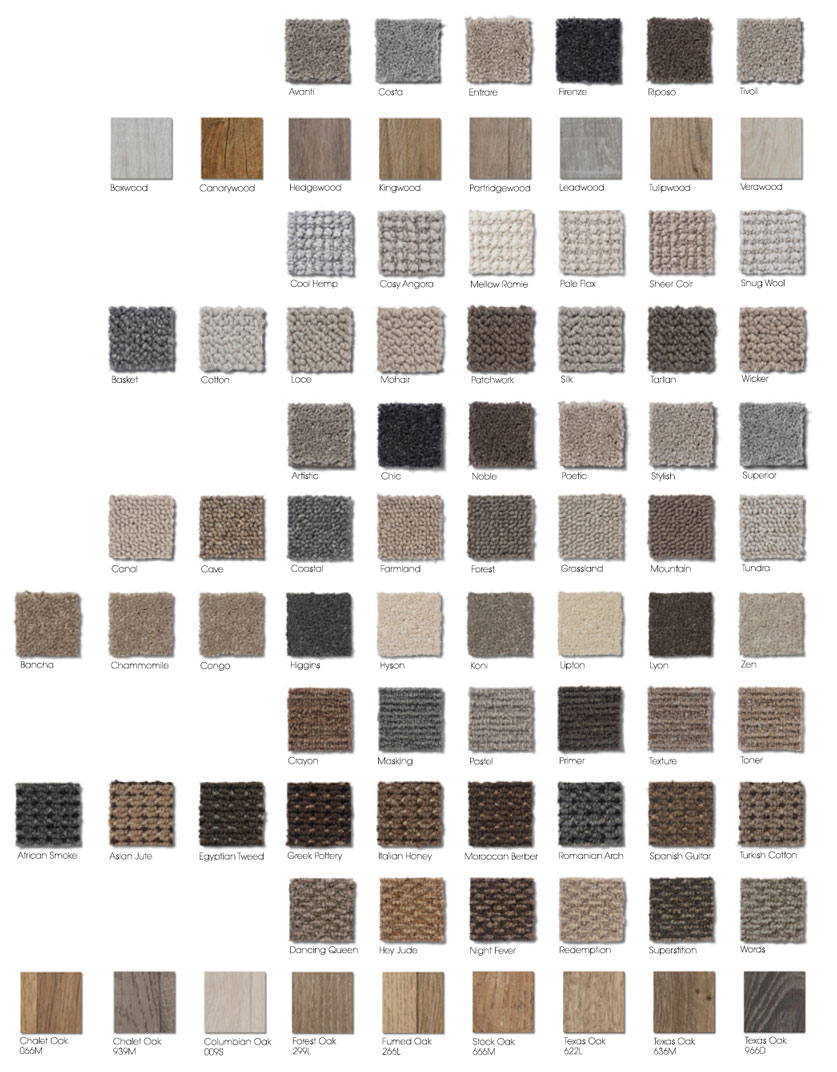

Laminate Floors

Laminate flooring is essentially a flooring system that is floating (glueless) with all systems having a click in joint that connect the planks together. Some manufacturers also produce ranges that can be installed completely glued to the subfloor, should this be the preferred way of fixing we suggest you confirm these details with the technical department of the chosen manufacturer.

Laminate floors are manufactured in two ways:

- High-Pressure Laminate (HPL) manufactured at 9653 kPa. (1400 psi)

- Direct Pressure Laminate (DPL) manufactured at 2070 – 3448 kPa. (300-500 psi)

Even though both laminate types are made of the same basic materials, the pressure used in the manufacturing process helps determine both hardness and performance.

High-Pressure laminates have the following advantages:

- Better impact resistance – no denting

- Better design clarity – higher sheen levels

- Better static load capacity – no dimpling

- Higher in-carton product integrity – less damage in handling, no chipped corners

- Better, wear resistance – fewer scuffs and scratches

Moisture

A moisture or vapour barrier installed below the laminate flooring is always recommended, especially when the flooring is to be laid directly onto a new or recently cast concrete sub-floor. Many manufactures also produce ranges that have a moisture resistant core, available in different classes, for areas requiring added water protection as well as those areas where wet cleaning methods are used e.g. a kitchen. (This however, does not promote the use of excess water and is more an added protection against the use of excess water and spillages).

Layered Wooden Flooring (Engineered)

The construction of layered wooden flooring is made up as follows; the wear layer or top layer on each plank is a selected

hardwood veneer. The middle layer consists of a high-density material, using a high-density fibreboard or plywood. The

bottom layer is made of pine, other softwoods or plywood, which allows the construction to perform flawlessly in a variety of