Knowing how to join metal is a skill worth knowing and can be the difference between fixing something or throwing it out.

Doing it right means we need to solder the join. Soldering for electrical connections is an easy but fundamental skill for homeowners and DIY enthusiasts. Whether you’re working on circuit boards or simply joining two wires together, the principle remains the same.

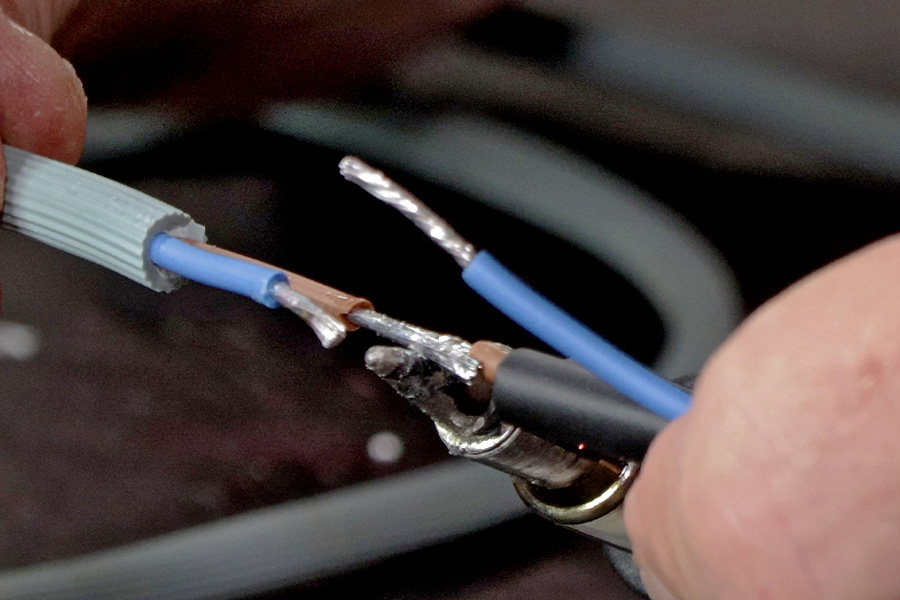

Soldering for a strong, permanent and safe electrical connection involves placing two ends of an electrical circuit, such as two ends of a cable, into hot molten solder. Solder is a very soft metal alloy made from tin and sometimes lead that melts at around 300°C. When cool, it forms a strong bond between the two metal surfaces.

The art of soldering is getting this right.

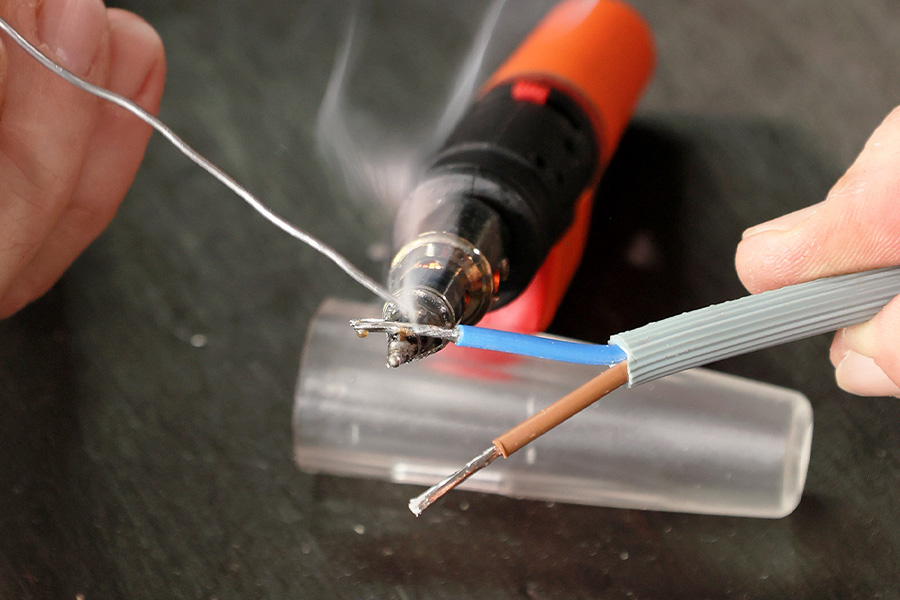

To solder properly, you need heat. The heat required to melt the solder is applied with a soldering iron, available in different sizes for different jobs. Solder wire is also sold in various sizes or gauges. For electrical work, you want a thin option – 1.2 mm is perfect.

Start by stripping the wire using wire strippers or pliers. At this point we’ll point out an optional step, applying flux. Some people use flux and others don’t but we recommend using it as it speeds up the process and gives more even coverage of the solder.

If you don’t use flux, just leave out that particular step. The solder will still stick to the metal but will take slightly longer and is more fiddly.

Do the same for all the cables and then slide the last heat shrink into place. Heat it so that it seals the join and you’re done. Now that it’s been repaired with a good solid join, this cable can go back into service.

For all soldering and electrical supplies (as well as new mower extension leads if the damage is too bad to repair!), visit Builders, either in-store or online at builders.co.za.